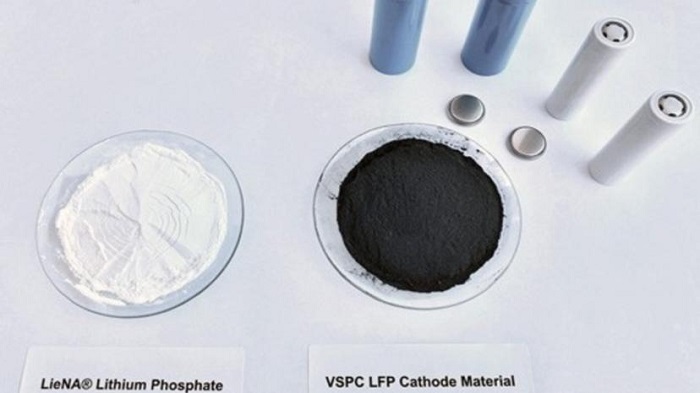

Lithium ferro phosphate and lithium manganese iron phosphate are phosphate-based cathode active materials that can be manufactured using VSPC’s patented nanotechnology process, according to LithiumAustralia.

The company says the new patent, which provides VSPC with 20 years of intellectual property or “IP” protection in Australia, represents the first milestone in VSPC’s quest for global patent protection of this IP.

VSPC has been simplifying the processing method for the production of lithium metal phosphate cathode powders over the past two years which it says has led to a wider range of raw materials being able to be used as feedstock.

By harnessing lithium phosphate as a cathode powder precursor, VSPC suggests its newly patented process has the potential to cut out the number of steps from mining of ore to the production of battery cathode materials and new lithium-ion batteries.

LithiumAustralia says VSPC’s technology offers several competitive advantages.

LithiumAustralia subsidiary VSPC’s patent application has been approved.

LithiumAustralia subsidiary VSPC’s patent application has been approved.

They include flexibility and choice in terms of the lithium raw materials used such as lithium phosphate, lithium carbonate or lithium hydroxide.

The company also says its technology can lower energy consumption and provide a precise up-front control of the chemistry to reliably deliver products consistent in their chemical and physical properties.

The VSPC patented process has also been shown to reduce chemical input costs by 15 per cent, the company says.

Chemicals typically speak for more than two-thirds of the total cost of producing cathode materials and LithiumAustralia says the cost savings could therefore be significant.

According to LithiumAustralia, global demand for lithium ferro phosphate has climbed more than 25 per cent over the past year or so, increasing Chinese lithium ferro phosphate cathode powder manufacturing levels to more than 100,000 tonnes per annum.

Respected independent research house Roskill points to the potential rapid take-up of lithium ferro phosphate by the electrical vehicle or “EV” industry, potentially driving demand for lithium ferro phosphate four-fold to 500,000 tonnes per annum by 2025 and to a whopping 1.3 million tonnes per annum by 2030.

Those numbers if achieved would elevate lithium ferro phosphate to one of the fastest growing sectors in the lithium-ion battery market.

LithiumAustralia says an expansion of lithium ferro phosphate cathode material capacity will be needed in China and also worldwide as demand surges for lithium ferro phosphate batteries in EV applications.

Their ability to replace lead-acid batteries in automobiles, back-up power supplies and stand-alone power for remote site applications also factors into the equation.

Read the original article on The West Australian.