The invention is based on nanocolloidal systems produced by means of ionic gelation of nanoparticles with different charge. They contain poly(ethyl methacrylate)-based polymer particles with different charges, which gives the material not just plasticity but also the ability to self-restore. The gels produced in such a way can be used for 2D imagery as well as in multilayer 3D printing, which offers many prospects for their use: from the creation of functional biological materials and films to the printing of optically active structures. Among the applications of the latter is anti-counterfeiting protection.

The tags developed at ITMO University can be applied not only on even surfaces, but also on those with complex geometry or morphology. It’s also worth mentioning that this method is not just eco-friendly and affordable, but also safe for both customers and products. It can be used to tag clothes, as it doesn’t damage fabrics and the tags can be easily removed with organic solvents. It can also be used in the food industry: the tags don’t percolate even through thin membranes, which makes it possible to use them in food packaging.

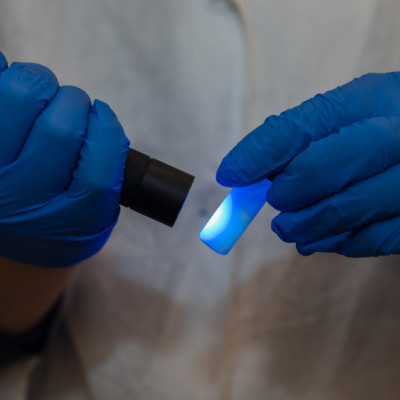

Ink for anti-counterfeiting protection. Egor Ryabchenko.

Scientists from ITMO’s ChemBio Cluster focused on the latter application, as anti-counterfeiting protection is not only promising, but also relevant.

The scientists plan to continue experimenting with the ink formula so that they can adjust it to the needs of specific industries. By changing the formula, the ink can be made better in terms of thermal resistance (this can be of use to the manufacturers of electronics and equipment), or in terms of plasticity (which is relevant for tagging clothes).

The research received support from a Russian Science Foundation and the Ministry of Science and Higher Education grant.

Read the original article on ITMO University.