3D printed electronics provider Nano Dimension, has signed a Memorandum of Understanding (MoU) with South Korean technology innovation hub Chungbuk Technopark (CBTP). A multi-year agreement, the two organizations will work to streamline the electronics manufacturing process chain. Products of the collaboration will benefit various areas of the region’s electronics industry, covering consumer goods, transportation, energy, bio-health and smart IT (e.g. IoT type devices). Nano Dimension’s DragonFly additive manufacturing system will be at the core of their work.

3D printing for “high-tech electronics” in South Korea

CBTP is a non-profit research institute supported by the South Korean government that encourages collaboration between local industry and academia. It has been active for 15 years, winning national awards in this time for its valuable contributions to research and business.

Founded in 2014, Nano Dimension provides hardware, materials and software to 3D print embedded, multilayer and non-planar electronics. The complete package from the company provides manufacturers with a faster and more cost-effective solution to PCB/electronic product development. Eventually, the company envisions it will also be able to apply its technology to the end-use production of custom, electronic devices.

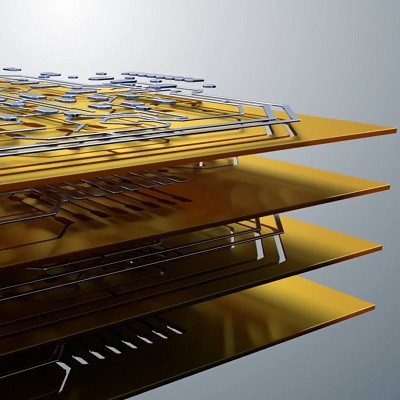

Example of Dragonfly 3D printed circuit boards. Image via FAPS Nuremberg.

Though October 28th marks the first public and formal announcement of Nano Dimension’s work with CBTP, the center’s researchers have already undertaken some development work with the DragonFly system. A fully functional, 3D printed IoT communication device is the first product of their partnership. The team has also produced capacitors in PCBs and side mount boards on the DragonFly. With these novel developments, manufacturers can save valuable space and weight in ever-shrinking electronics designs. “We are proud to work with CBTP […] to continually advance additive manufacturing of electronics and pave the way for innovative applications,” said Amit Dror, CEO of Nano Dimension. “We are constantly developing and presenting exciting new applications and providing our customers cutting-edge solutions for electronics design and manufacturing.

As indicated by the South Korean government’s investment in the 3D printing industry, the nation that CBTP represents is committed to becoming a hub for excellence in electronics. Song I. Hun, Director of the Semiconductor IT Center at CBTP, commented, “This research agreement is an excellent platform to work together with Nano Dimension on a long-term program of research focused on the crucial design and prototyping phases of innovative electronic projects.

A new strategy for Nano Dimension

Following results below management’s expectation for Q2 and H1 2019, Nano Dimension has been undergoing a strategic restructuring of late. This has included a “review of strategic alternatives,” and saw Nano Dimension CBO and Co-Founder Simon Fried to step back on to the company’s board of directors. The launch of the company’s new DragonFly LDM model (Standing for “Lights-Out Digital Manufacturing”) was also an important part of the company’s move forward, signifying a move to higher electronics throughput. Commenting on the strategy at the time of the announcement, Dror added, “We believe that the combined actions we have taken position the company’s products and structure better for sustainable growth.”

Read the original article on 3D Printing Industry.