Ultraviolet nanoimprint lithography (UV-NIL) is a manufacturing technique for producing nanostructures using UV-curable resin. One of its main advantages is its sheer simplicity; UV-NIL essentially consists of pouring a liquid resin over a nanostructured mold, making the resin solidify using UV irradiation, and then releasing it from the mold. The result is a solid polymer with a nanostructure that is the inverse of that of the mold. Using this technique, a great variety of functional devices and thin films can be made for applications in fields such as optics, electronics, healthcare, biology research, and solar cells, to name just but a few.

It is safe to say that the most valuable piece of equipment in the whole UV-NIL process is the master mold. To make them last longer, replica molds made from the master mold are made and used for the mass production of nanostructured devices. However, these replica molds are not as durable as the master mold, and they generally begin to show macroscopic signs of wear after a couple thousand imprints. Unfortunately, no reliable and standard method to predict the lifetime of replica molds exists-yet.

Measuring how a drop of water makes contact with the grooves of a nanolithography mold to find out how worn out the mold is.

In a recent study published in Nanomaterials, researchers from Tokyo University of Science and Autex Inc., Japan, came up with a clever strategy to tell when a replica mold will break. They managed to do this by looking at water droplets placed on top of a mold with a pattern of spaced parallel lines and noting how the adherence of the droplets changes as the mold wears out and distorts with use.

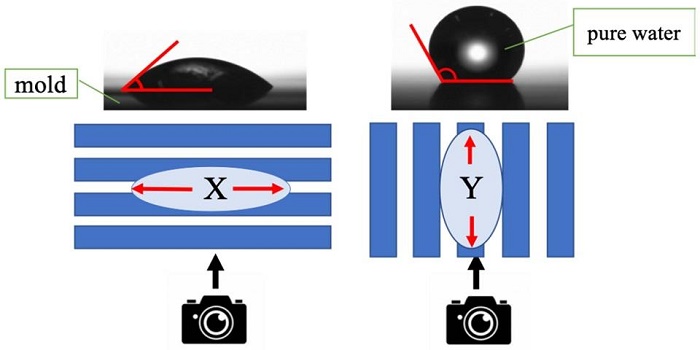

But how does such a method work? Liquid droplets resting on a surface have a measurable property called contact angle, which is the angle at which the liquid meets the solid at the interface. This angle is easily measurable using commercial camera-based systems.

Now, in a nanostructured mold with parallel lines (grooves), the contact angle of water exhibits anisotropy, meaning that it varies along different directions. More specifically, a water droplet placed on a pristine mold with parallel grooves will spread along the direction of the grooves more than in the direction perpendicular to the grooves. However, the researchers noticed that, as the mold wears out with repeated use, the contact angle changes differently along each direction.

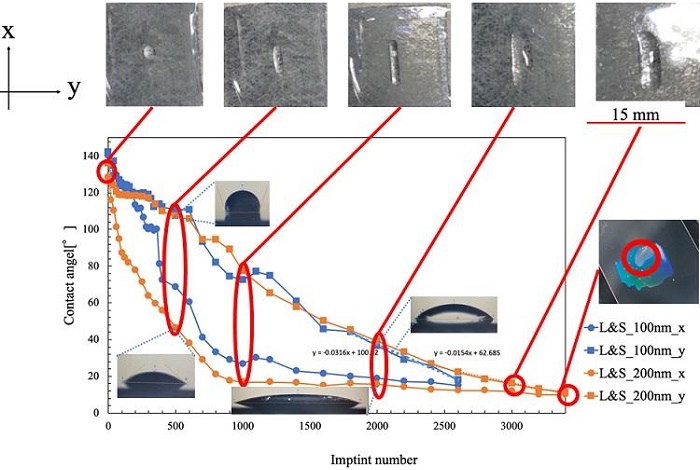

Professor Jun Taniguchi from Tokyo University of Science explains: "As the number of uses of the mold increases, the contact angle along the direction parallel to the grooves decreases linearly. In contrast, the contact angle along the perpendicular direction decreases much more quickly at first and then stays at a constant minimum value. We found that molds tended to become defective almost exactly when the number of repetitions made the contact angles in both directions equal."

The researchers verified their method using molds with different groove widths, and the results held up (see the accompanying Figure). This means that one can make accurate predictions about the remaining lifetime of a mold with parallel grooves through a simple process. First, check that the contact angle in the perpendicular direction has reached a stable minimum value. Then, compute the decreasing line function with the stored values for the contact angle along the parallel direction. Finally, calculate the number of uses after which this line will intersect the minimum value; the mold will most likely break around that number.

Plot of the contact angle along the parallel (y) and perpendicular (x) directions versus number of uses of the mold. The mold becomes defective when the contact angle along the vertical direction becomes equal to the stable minimum value along the perpendicular direction.

This simple approach will be useful to determine the expected lifetime of molds for UV-NIL. "Though our method is only applicable to molds with parallel grooves, it can be used to assess the durability of mold materials themselves; the predicted lifetime of a mold material applies to virtually any shape," remarks Mr Shin Hiwasa from Autex Inc. Overall, this study fills an important knowledge gap in UV-NIL, reducing its associated costs by providing an easy way to predict when molds will wear out.

The proposed strategy will hopefully make this nanoimprinting technique more accessible and reliable, fostering its adoption both in research and applications for everyday life.

Read the original article on Tokyo University of Science.