ElastiDry Protective Coating, a Pacific Northwest National Laboratory (PNNL) invention, emerged as the winner at the recent National Labs Accelerator Pitch Event. ElastiDry is a groundbreaking liquid-repellent material that could be applied to personal protective equipment such as gloves, face shields, shoes, or protective suits to reduce infection and contamination in health care settings.

A panel of five judges from the Bay Area and Silicon Valley investment community chose the PNNL innovation from 10 product pitches, all from different national laboratories. The U.S. Department of Energy (DOE) Office of Technology Transitions (OTT) awarded PNNL a $25,000 prize to spend toward further ElastiDry commercialization activities.

“At the Department of Energy, we spend a lot of time working with the national labs to ensure their groundbreaking research has a chance to become a product that improves American lives,” said DOE Chief Commercialization Officer and OTT Director Conner Prochaska. “Thanks to our dedicated lab staff and private-sector partners, technologies like ElastiDry will advance U.S. technological leadership and keep us safe and secure.”

PNNL is seeking a private-sector partner for ElastiDry to bring the product to market. At the same time, PNNL recently launched a new program through which entities can obtain evaluation samples through a research-use agreement and a modest fee.

Product developer makes the pitch

Curtis Larimer, the PNNL materials scientist who has led the nearly three-year effort to develop the superhydrophobic material, presented ElastiDry to the judges.

“I was thrilled to be representing PNNL and to be representing the team that has put so much work into ElastiDry,” said Larimer, who prepared a video presentation and fielded the panel’s follow-up questions.

“We’ve been working very hard to get the technology to this point – to make a compelling presentation at the pitch event,” said Larimer. “I was honored to be chosen as the winner on that day.”

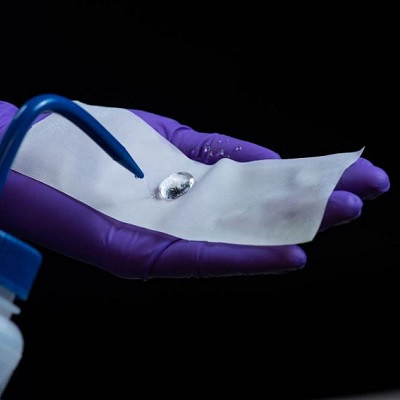

To create the new material, Larimer and PNNL team members experimented with mixtures containing hydrophobic silica, a microscopic particle derived from sand that’s a common ingredient in a variety of products, including paints, plastics, and coatings. The winning mixture proved super repellent when applied to a latex glove and—to the researchers’ surprise—even more water repellent when stretched.

A targeted pitch

In his presentation to the judges, Larimer emphasized the potential application for surgical gloves, noting that a superior repellent could prove to be lifesaving in thwarting diseases—such as COVID-19—that can be transmitted by bodily fluids.

“Startups must be laser-focused on getting a product into the marketplace,” said Larimer. “So even though ElastiDry can be used in multiple applications, I had to narrow the scope. For this pitch, it was surgical gloves.” Larimer had help in perfecting the pitch.

PNNL’s Office of Technology Deployment and Outreach held an internal competition for ElastiDry and a few other PNNL-developed technologies in mid-November, choosing ElastiDry to proceed to the national stage. A panel of local business leaders, including entrepreneurs and representatives of the Tri-City Development Council, listened to the presentations and offered suggestions.

“It was valuable to hear from business leaders in the community,” said Larimer. “They suggested presenting more detail on the market I was targeting. They also said to know your audience and to speak to the judges as business investors, not technical people. I incorporated both of those tips into my video presentation.

ElastiDry’s ability to repel liquids—called superhydrophobicity (literally “water fearing”)—enhances its capability of keeping users clean, protected, and safe.

Tech deployment office helps with pitch

Larimer also credited PNNL Commercialization Manager Allan Tuan for promoting ElastiDry as a candidate for the national competition and efforts to bring the product to market.

“PNNL’s tech transfer team does really important work,” Larimer said. “The technical staff at a national lab can’t really afford to spend the time that’s needed to get technologies from the lab bench to the real world. As scientists, it’s crucial that we have this group of talented people to step in and carry the technology for the critical last mile—to market.”

After winning the internal PNNL competition, Larimer created and refined a 10-minute video before submitting it to the one-day competition, held as a Zoom webinar. He felt thoroughly prepared for the question-and-answer session because of his intimate familiarity with the product and past training in DOE’s Energy I-Corps, a key OTT initiative. The program pairs researchers with industry mentors for an intensive two-month business training.

The winning pitch and the next steps

When the five-member panel asked their questions, Larimer felt nervous, but ready. “You’ve got really talented and sharp reviewers who are going to ask incisive questions,” said Larimer. “When you do well in a presentation, you know it, you feel it. I felt like I addressed their questions succinctly and thoroughly.”

With a new year ahead, and with the award in hand, Larimer anticipates continued PNNL promotion and refinement for ElastiDry.

“We’re going to spend the first part of 2021 reaching out and securing a commercial partner,” said Larimer. “On the research side, we’re going to continue making improvements and modifications. We have plans for improvements to the material’s durability and functionality, and for additional intellectual property creation.”

The UC Davis Institute for Innovation and Entrepreneurship presented the accelerator pitch event in December in partnership with the national labs.

Read the original article on Pacific Northwest National Laboratory (PNNL).