Smart textiles can have numerous applications in consumer electronics, energy harvesting, energy storage, healthcare and fitness, smart buildings, sensors, and e-skin for soft robotics. The project aims to develop technologies in the area of fiber-based materials for non-clothing applications from Technology Readiness Level (TRL) 4 (technology validated in lab) to TRL 6 (technology demonstrated in relevant environment).

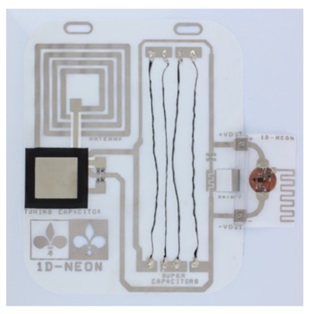

1D-NEON’s 9-million-euro project is funded under the Horizon 2020 program of the European Commission. This project is coordinated by the University of Cambridge and attended by 13 other participants. In addition, a number of renowned companies like Philips and LG giants are involved in the project. For example, LEDs are being designed by Philips and Henkel in order to be miniaturized to the nano-scale and transformed into fibers, while the storage of energy in supercapacitors is being improved by CeNTI (Centre for Nanotechnology and Smart Materials, one of the participants of the project).

"Let's suppose you’d like to make a television. In this case, a TFT would be what is intended here, but in the form of a screen, which would be made of textile. It is clear that, for the screen, we need a transistor, electrodes, LEDs, sensors, and power. So, we need to transform these five components into threads and then we'll pick up these five threads and try to put them all together in a textile structure,” the researcher Nélson Durães, head of the team of fibers and polymers of CeNTI explained.

The results can revolutionize the way opto-electronic devices will be produced in the future. "When we look at the end products, we can think that it is possible to obtain a textile having the intended characteristics, as is the case here. In other words, it is possible to have an image, light, and other characteristics similar to those in a conventional screen[T J1]. If we happen to join these two worlds, it will be a huge improvement in terms of the commercial impact, "concluded Nélson Durães.

From the point of view of the material, six classes of materials including conductive percolated polymers and nano-composites, carbon nano-fibers and active semiconducting materials, organic and inorganic emissive compounds, nanostructured materials for fiber-based energy devices, tactile sensitive materials and conductive, and non-conductive adhesive materials are employed for developing optoelectronic devices.

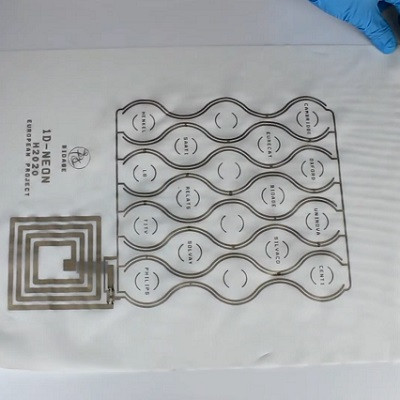

Figure 1. A smart screen with LED matrixes.

Dr. Luigi G. Occhipinti, exploitation and business development manager and work-package leader for exploitation and dissemination, asserted: “The 1D-NEON project represents a unique opportunity to bring about innovation in technical textiles by embedding electronic, sensory, and energy functionalities into active fibers. The new manufacturing platform will use processes widely adopted by the textile industry, from multi-layered fiber extrusion to weaving, knitting, or braiding techniques, in order to make circuits and multifunctional systems that are intrinsically flexible and stretchable.”

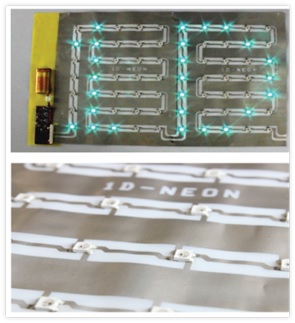

Figure 2. light-emitting fibers.

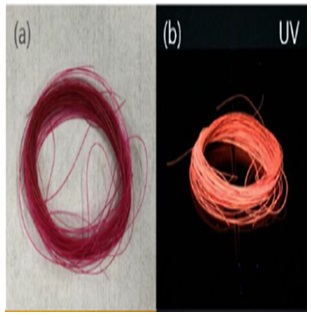

Some of the achievements of this project include conductive fibers, LED matrixes, antennas, transistors, capacitors, and supercapacitors on fibers, piezoelectric fibers with the aim of energy storage and harvesting, light-emitting fibers, and fibers for electrodes in the form of articles and prototypes.

Figure 3. A supercapacitor with a temperature sensor on fibers.

“The key objective of future manufacturing research hubs in this area will be to create a bridge between the electronics and textile industries,” said Brian J. McCarthy, who leads the Knowledge Transfer Network on textiles in the UK.

It seems that the results of the project will help giant electronic companies to achieve huge prosperity in the field of stretchable, wearable, and cloud-connected optoelectronics devices.