“As a leading facility in electrochemical research, it’s crucial that we continue to invest in state-of-the-art capabilities such as nano-CT,” said Senior NREL Energy Storage Researcher Donal Finegan. “This scanner expands our capabilities at NREL with a new spatial resolution of 50 nanometers, a limit otherwise only achievable at high-energy synchrotron X-ray facilities.”

Significant improvements to the resolution of nano-CT systems open the door to advances in how we analyze and understand battery materials. As the sample rotates, an X-ray beam creates 3D images with extreme resolution. As a result, this imaging method allows researchers to examine the properties of battery materials, such as their crystal structure, chemical composition, and 3D architectures. Given the nondestructive nature of nano-CT, researchers can view changes as they occur in real time to understand the reactions within a battery during operation or cycling.

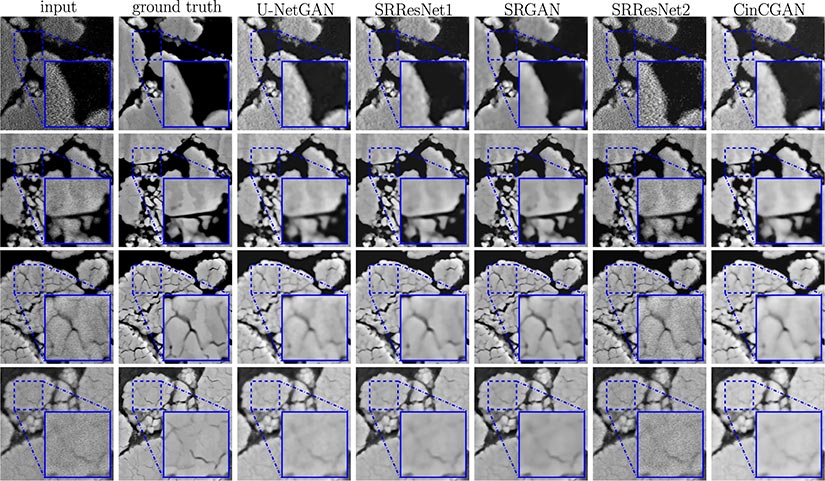

A visual comparison of super-resolution microscopy imaging obtained by five trained networks

Future Opportunities in Battery Research

A collaborative Nature Nanotechnology review authored by leading nanotechnology scientists at NREL, University of California (UC) San Diego, Université de Picardie Jules Verne, and Thermo Fisher Scientific expands on the history and evolving trends in battery diagnostic imaging and opportunities for applying machine-learning techniques to improve existing imaging and computational modelling capabilities.

Machine-learning techniques train computers to build models to predict outcomes and automate analysis processes. Combined with nano-CT, machine learning can develop predictive models to analyze how the electrode microstructure or material heterogeneities—such as the uniformity of particle shapes—impact electrochemical responses. As a result, researchers can quickly review complex data sets to identify new solutions for next-generation battery designs.

In addition, modeling tools, such as generative adversarial networks (GANs) can enhance the resolution of digital images and bridge gaps between diagnostic imaging scales to provide a holistic view of Li-ion electrode particle morphology, or simply put, its structure. For example, the shape and size of electrode particles can vary widely, and multiscale imaging is critical to understanding how batteries work. Degradation mechanisms—or material inconsistencies that negatively affect the lifetime, safety, and reliability of batteries—appear across different magnification scales if researchers know where to look.

NREL, in collaboration with researchers at the University of Ulm and Argonne National Laboratory, recently published a demonstration in Nature Partner Journal (NPJ) Computational Materials on how GANs can be applied to enhance the resolution of microscopy images and enable the ability to quantify small features that are invisible to the naked eye, such as cracks in electrode particles.

“We hope to use this new nano-CT scanner to inform future synthesis and manufacturing techniques for next-generation battery materials,” Finegan said. “The ability to perform imaging of this resolution in-house allows our research team to gain deeper insights—quicker—into materials that are more resistant to degradation mechanisms, such as particle cracking. This capability, in conjunction with other microscopy techniques and novel machine-learning methods, expands our characterization reach to a whole new limit.”

Read the original article on National Renewable Energy Laboratory (NREL).