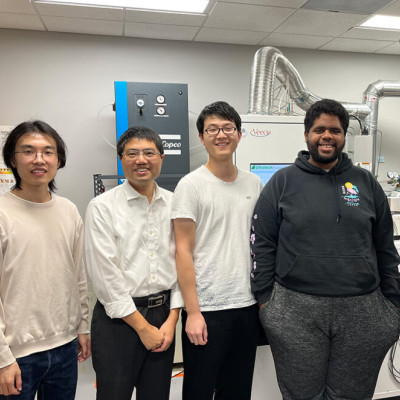

A University of Central Florida research team with collaborators at Virginia Tech have published critical findings about the electrochemical synthesis of ammonia, advancing sustainable fertilizer research and thus aiding global food safety efforts.

Ammonia, a compound of nitrogen and hydrogen, is an essential ingredient in many fertilizers for food production. However, its primary method of production, the Haber-Bosch method, is energy and fuel-intensive, consuming 3% to 5% of the world’s natural gas output and accounting for more than 1% of global carbon emissions.

While there are many research efforts on electrochemical ammonia production, the underlying mechanisms have yet to be better understood.

Using the metal ruthenium as a catalyst, researchers identified the most efficient way to produce ammonia through a more sustainable production method — electrochemically. This production method can be more sustainable when electricity from renewable sources, such as solar or wind, is used to power the electrochemical synthesis, the researchers say.

The findings were published recently in ACS Energy Letters.

While there are many research efforts on electrochemical ammonia production, the underlying mechanisms have yet to be better understood, the researchers say.

However, this new research helps provide a clearer picture of the reaction mechanism, says study co-author Xiaofeng Feng, a professor in UCF’s Department of Physics.

“The results of this in-depth work can provide important guidance to researchers on how to design more efficient catalysts towards sustainable ammonia production,” Feng says.

How They Did the Work

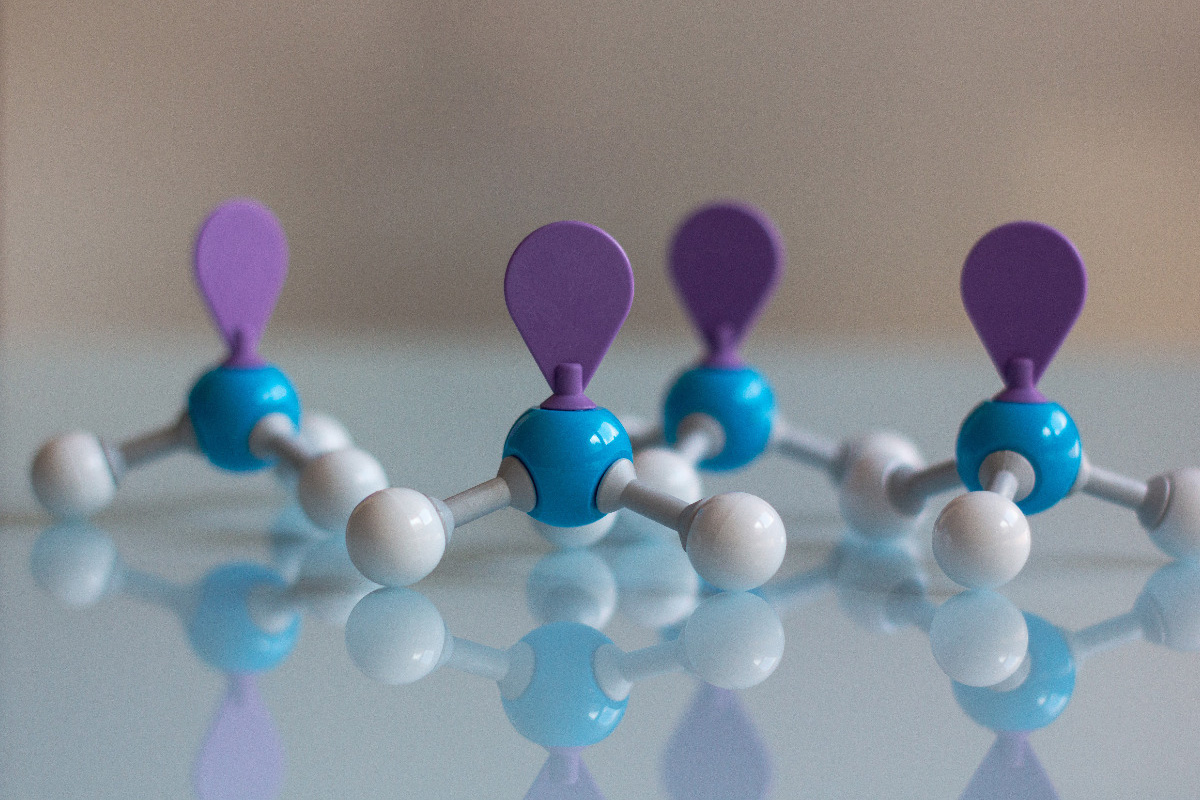

Ruthenium’s optimal binding strength with reaction intermediates makes it one of the most active catalysts for the nitrogen reduction reaction, which produces ammonia by combining nitrogen with hydrogen from water molecules.

Using atomic layer deposition, the researchers were able to have very precise control of the synthesized nanomaterials at the atomic scale, allowing the testing of ruthenium nanoparticles ranging from two to eight nanometers.

Researchers discovered that while layering ruthenium atoms into a catalytic structure, a special arrangement of ruthenium surface atoms — named the D5 step site — was the most active site for the electrochemical nitrogen reduction reaction.

Unlike other sites, the D5 step site possesses the “perfect balance,” favoring the formation of the N2H intermediate and not getting poisoned, or rendered unable to allow new molecules to adsorb and react, by the NH2 intermediate, the researchers say.

Ruthenium nanoparticles of around four nanometers in size were thus found to have the best catalytic performance for the nitrogen reduction reaction. Activity peaked at four nanometers and then dropped by five-fold as the particle size was doubled, demonstrating the critical effect of ruthenium particle size on the catalysis.

The researchers’ previous work to improve the efficiency of the electrochemical production of ammonia helped the current study by providing the mechanistic understanding and research methodology.

Read the original article on University of Central Florida.