2023-04-08

Visited : 1430

Already touted as a cleaner, more efficient source of renewable energy, perovskite solar solutions stand to see further improvements with the incorporation of graphene.

The race for large-scale renewable energy solutions is in full flight around the world. Far more than being nice to have, renewables are a mandated and growing part of the energy mix for many governments.

However, there is a large overhead associated with the decommissioning of current infrastructure and the production and rollout of new infrastructure requirements, including generation, transmission and storage, that in many cases bring the true sustainability claims and return on investment into question.

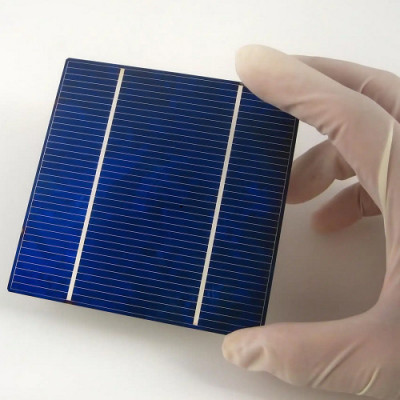

For example, the most common solar panels use silicon photovoltaic cell technology, which is made in large quantities in fossil-fuel powered manufacturing facilities in China. With the recent issues impacting China’s trade relations, as well as energy security arising from the Ukraine-Russian conflict, bringing infrastructure manufacturing requirements in-country is a greater focus for many nations.

Changing the solar equation

Solar power is one of the cleanest power sources available, but as described above, the creation of the necessary infrastructure can be problematic. There are also issues with performance of the commonly used silicon photovoltaic cells in areas that receive a lower intensity of solar radiation.

In addition, generating solar power on an industrial scale requires a large footprint – feasible where there’s plenty of open space, such as in desert areas, but that often necessitates requirements for lengthy transmission infrastructure.

In countries such as Australia, rooftop solar has experienced significant growth across both residential and commercial applications. Once restricted to daylight hours, more recent advances in battery technologies have seen behind-the-meter storage start to gain traction, meaning solar power becomes a 24×7 possibility, using sunlight during the day to generate enough energy to carry households and businesses through the night. But sunlight is the operative word and backup power supplies are still required to provide energy when generation cannot keep pace with demand.

Nevertheless, the advent of rooftop solar highlights two things. Firstly, the real estate required for solar energy is quite literally available in the existing infrastructure, so large-scale solar farms can be reimagined. Secondly, it shows that energy generation can become far more individualised instead of requiring large utility organisations and/or government ownership. That becomes even more of a priority given the spotlight on energy security brought about by the pandemic and Ukraine conflict.

Now, novel perovskite solar technology is showing promise to further downscale energy generation – to a device level – but more importantly to provide far better conversion of light to electricity. The beauty of perovskite technology is that it works in low and ambient light.

Perovskite technology explained

Perovskites are a range of naturally occurring minerals with a unique crystal structure that are used in a range of applications including piezoelectric, batteries and superconductors.

Perovskites are also one of the most effective forms of Ultra Low-Cost Solar (ULCS), allowing the creation of thin-film solar cells. Compared to other solar technologies, they offer a tunable chemistry leading to high energy conversion and can be made in very small, flexible formats with low weight configurations. Most importantly, they are effective at generating power in indirect or ambient light conditions. They also require far lower temperatures than in the manufacture of silicon-based cells, hence enabling much lower carbon emissions from the manufacturing process.

Being able to create these small-scale ULCS cells opens the way for a greater range of highly effective, device-centric charging applications – think phones, lighting, household appliances and a broad range of consumer electronics with inbuilt solar charging capabilities.

Further consideration, with energy security issues being a major concern, is that manufacturing can be carried out in relatively small-scale facilities, in-country and at multiple local facilities rather than requiring extensive floor space and carbon-intensive industrial processes.

For Australian company Greatcell Australia, which has established a pilot plant in New South Wales and is in the advanced stages of testing its range of Perovskite Solar Cells (PSCs) with manufacturers around the world, the ability to provide new sovereign capabilities in clean energy is key.

Greatcell is aiming to fit its modular production lines into 40-foot shipping containers, due in part to the easier assembly and reduced number of steps to produce PSCs compared to silicon solar cells.

The graphene advantage

There have been challenges with PSCs, particularly with regards to extending their lifetime for viable commercial applications. Greatcell realised that by rethinking the materials in PSCs, these challenges could be overcome. Graphene, a cutting-edge advanced material, has demonstratable performance enhancements over other existing PSC technologies, leading to a collaboration between Greatcell and First Graphene.

Graphene is seen as the key to enhancing many of the key properties of PSCs that already make them appealing for a vast range of everyday applications. It can also improve service life and allows high-speed roll-to-roll production. In addition, due to graphene’s exceptional electrical conductivity and thermal properties, there is good potential for improved energy conversion efficiency. Graphene is also seen as the key removal of environmentally hazardous materials currently used during the manufacture of perovskite solar cells.

In addition, Greatcell Australia CEO Paul Moonie says the graphene composites and formulations developed through the collaboration not only result in PSCs delivering enhanced performance but provide over 80 per cent reduction in input material costs.

“This opens the way for even lower cost options that will undoubtedly be a compelling proposition for global electronics manufacturers,” he says.

According to Michael Bell, CEO and Managing Director of First Graphene, the collaboration with Greatcell offers considerable opportunity for both companies.

“We’re aiming to fast-track the commercialisation of the new graphene-enhanced PSC technology, which could open the way to a considerable global market that needs better performing perovskite solar technology,” he says.

Read the original article on First Graphene.