In recent years, intensive work has been dedicated to develop simpler and cheaper energy production methods to meet increasing power demand. The in-situ conversion of mechanical or solar energy into electricity is a feasible solution to satisfy the power demand of emerging technologies such as the Internet of Things (IoTs). Harvesting of environmental mechanical energy is a particularly promising solution, and many mechanisms have so far been explored to convert it into electricity.

A triboelectric nanogenerator (TENG) is considered as a potential solution to address the issue at hand owing to its comprehensive advantages including light weight, small size, a wide choice of materials, and high efficiency. The output of conventional TENGs has two built-in characteristics: first, they produce AC output, thus requiring a rectifier for generating DC output; second, their pulsed output results in a very high crest factor which seriously influences their performance.

Very recently, a continuous DC output has been achieved using the sliding Schottky nanocontact technique; however, the output voltage is too low (~ 8 mV) to drive electronics directly.

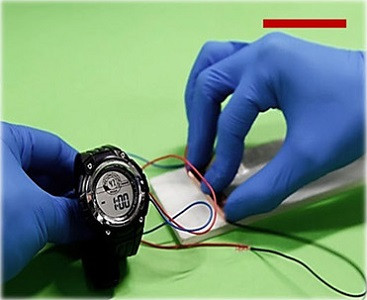

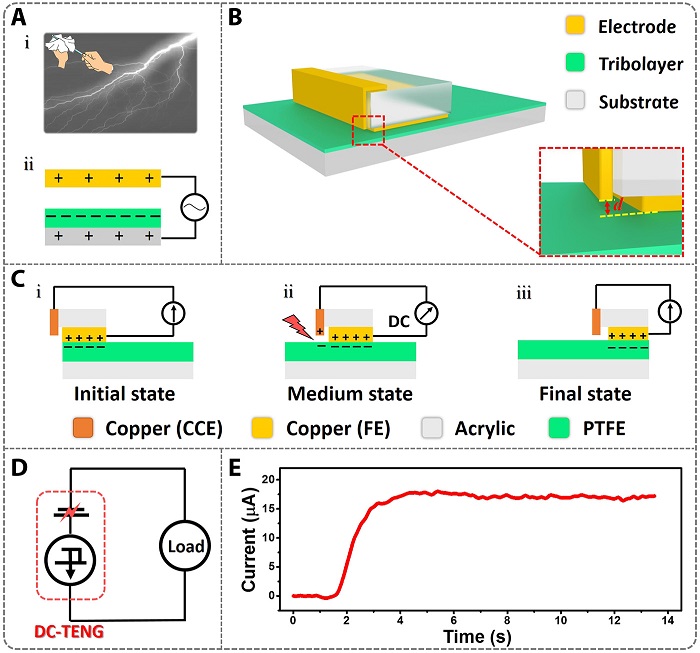

The researchers of Beijing Institute of Nanoenergy and Nanosystems, Chinese Academy of Sciences, and Georgia Institute of Technology have developed a special triboelectric nanogenerator which can make DC output with high voltage. This triboelectric nanogenerator, known as direct current triboelectric nanogenerator (DC-TENG), is designed based on the triboelectrification effect by inducing artificial lightning. It is composed of a charge collecting electrode (CCE), a frictional electrode (FE), and a triboelectric layer. The CCE layer is fixed on the side of a sliding acrylic substrate, with a subtle distance to the triboelectric layer which is a PTFE layer attached to another acrylic sheet. Here, both CCE and FE are copper electrodes.

Fig. 1 Working principle of the DC-TENG

In the initial state, the FE is in left alignment with the PTFE film and is in contact with PTFE, and there are positive charges on the FE and negative charges on PTFE caused by the triboelectrification effect (stage i). PTFE film can hold a quasi-permanent electric charge. Thus, in the medium state when the slider moves forward under an external force, a very high electrostatic field is built between the CCE and the negatively charged PTFE film which can cause the nearby air to partially ionize and begin conducting. This will result in electrons flowing from the PTFE to the CCE, thus reducing the potential difference (stage ii). In this system the CCE induces air breakdown, creating artificial lightning. Instead of allowing air breakdown to happen spontaneously and having its energy untapped in a conventional TENG, the CCE effectively collects these charges. The discharging process will continue until FE is in right alignment with the PTFE film (stage iii).

Because the inner flow direction of electrons is fixed from the FE to the PTFE film and then to the CCE, the output electrons will also be in a single direction. When the slider moves backward to the initial state, no current flows in the external circuit because there is not enough potential difference across the CCE and the PTFE film. Hence, a cyclic DC output can be produced using this technology with the voltage of 750 V and the charge density of 430 μC.m−2, offering a far better alternative to conventional batteries in various applications.

The results of this study have been published in the Science Advances journal with the title of "nanogenerator arising from electrostatic breakdown."