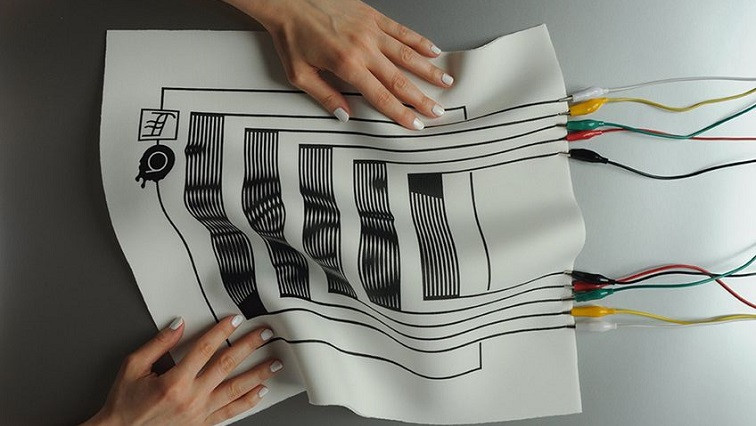

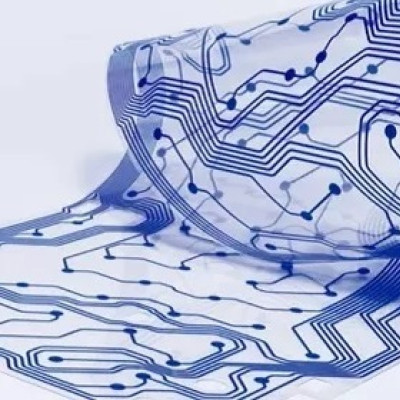

Electronic textiles (e-textiles) involves electronics and interconnections knitted or printed onto or into textiles, which enable the integration of electronic functions and attachments. Components and interconnections are natural to the fabric structure, which decrease the chance to be seen, twisted together or tore apart by the surroundings. Electronics that can be hanged over a vehicle or a tank is achievable using textile fabrics.

The ideas for e-textiles have been around for decades, but with increasing commercial focus in the last 30 years. They are of great interest as they have various industrial applications such as health monitoring, sports training data acquisition, tracking the position, and status of soldiers in action, monitoring pilot or truck driver fatigue, and so on.

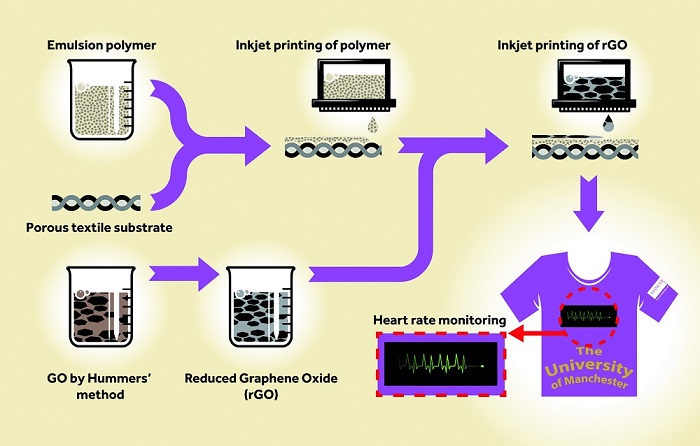

Researchers at the University of Manchester have reported inkjet printing of highly conductive graphene-silver nanoparticles-based composite ink for wearable e-textiles applications for the first time. Inkjet printing is one of the most promising methods for the fabrication of flexible and wearable electronics, owing to a number of advantages compared to conventional manufacturing techniques including reduction in material waste, digital and additive patterning, deposition of a controlled quantity of materials, and compatibility with various substrates. Currently, silver nanoparticles-based inkjet inks are the most utilized conductive inks; however, the higher price of silver increases the processing cost, which restricts using this method.

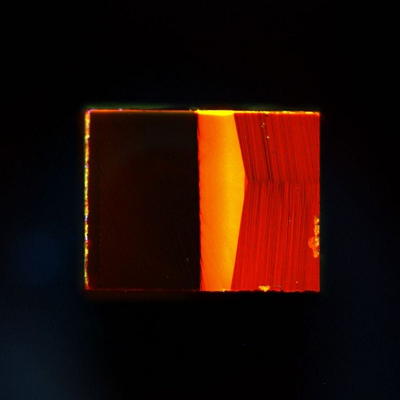

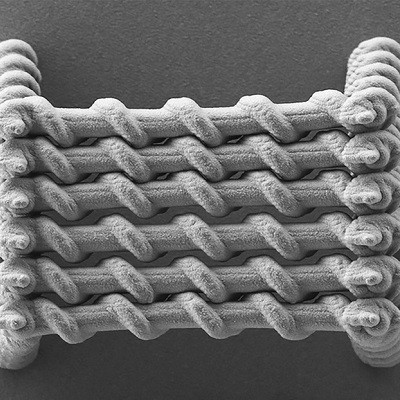

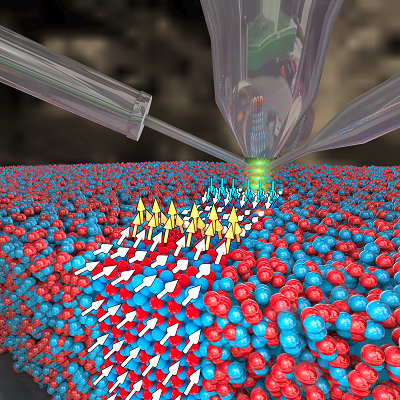

Inkjet printing of graphene-based inks is a promising approach as both the advantages of inkjet printing and the remarkable electronic, optical, and mechanical properties of graphene can be exploited. Reduced graphene oxide (rGO) is an excellent choice to fabricate flexible devices, but the conductivity achieved with rGO inks is limited. In order to overcome such limitations, pristine graphene inks were developed and used for printing; however a number of obstacles still exist with these inks, that is lower graphene concentration and residual solvent in the printed electronics, higher annealing temperature, and the number of inkjet layers needed to achieve the desired conductivity.

To overcome these problems, the researchers developed the formulation of highly conductive silver nanoparticles decorated graphene-based composite inkjet ink with which the desired electrical conductivity can be obtained with few layers of printing. The formulation was optimized using a cube film applicator first, and then a range of composite inkjet inks was formulated. Finally, the optimized graphene-silver composite ink was printed on the surface of pre-treated textiles (by inkjet) for highly conductive wearable e-textiles applications. This achievement will open up so many potential applications of graphene-based wearable e-textiles, where higher electrical conductivity is desired.

The results of this study have been published in the Scientific Reports journal with the title of "All Inkjet-Printed Graphene-Silver Composite Ink on Textiles for Highly Conductive Wearable Electronics Applications."