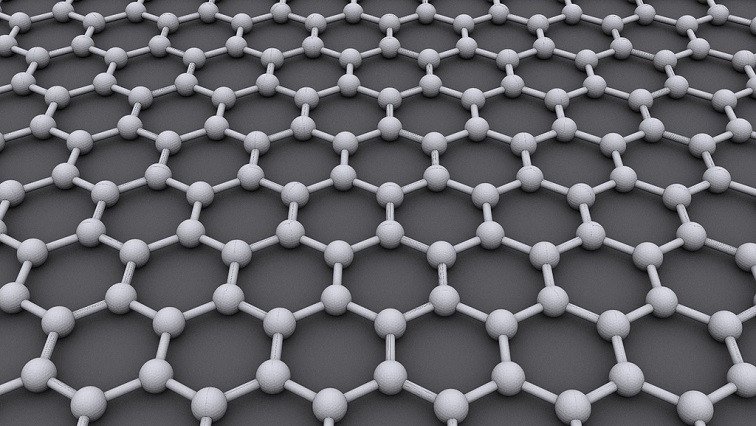

The project is aimed at supporting the scale-up of graphene oxide production by ZEN so that the miner can supply it to Evercloak. The nanomaterials manufacturer, on the other hand, will work on scaling up its membrane production process.

“Graphene has long promised to deliver immense benefits across a diverse range of technology applications. This collaborative project between Zen and Evercloak will fundamentally transform the manufacturing of graphene thin films and will bring forward environmentally friendly solutions in strategic clean technology areas including energy efficiency separation processes, batteries and solar cells to generate sustainable solutions for Canadians,” John Laughlin, NGen’s CTO, said in a media statement.

Evercloak’s patent-pending HydroAM printer is capable of depositing both 1D and 2D nanomaterials and transferring these ultra-thin films onto flexible substrates with a controlled density for various applications ranging from transparent conductors for flexible electronics to more efficient membranes for industrial separations.

To support this work, Zen will optimize and scale-up the electrochemical exfoliation process that was developed by a team at the University of Guelph to produce graphene oxide from Albany Pure Graphite.

The trademarked product is sourced from the company’s microcrystalline Albany deposit in northeastern Ontario.

Read the original article on Mining.