The current situation with the COVID-19 pandemic underscores the importance of detecting infections quickly and accurately to prevent further spread. Today, symptoms provide the clues that help diagnose viral or bacterial infections. However, many infections have similar symptoms, so these signs can easily be misread and the disease misdiagnosed. Blood tests provide certainty, but laboratories only carry these out when prescribed by the family physician. By the time the results arrive from the lab, doctors have often prescribed an antibiotic that may well be unnecessary.

Just one drop of blood for a diagnosis

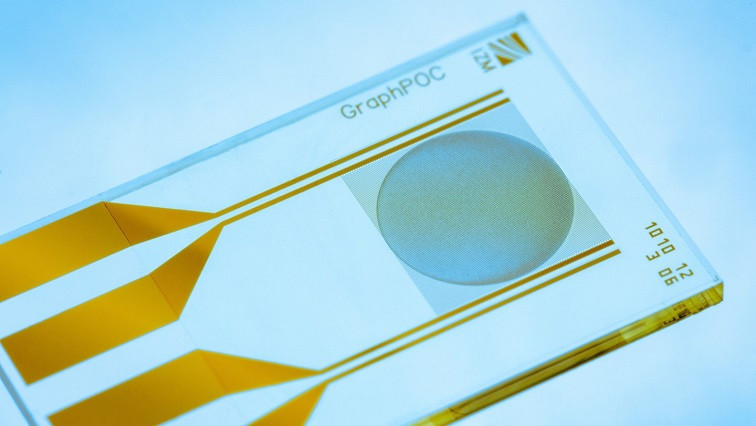

Researchers at the Fraunhofer IZM in Berlin have been working on the project Graph-POC since April 2018 on a graphene oxide-based sensor platform to rise to precisely these challenges in diagnosing infections. A single drop of blood or saliva is all it takes to perform an accurate analysis. Just a few minutes after the drop is applied to the sensor’s surface, electrical signals convey the test result to the family doctor’s office. This rapid test provides certainty within just 15 minutes to replace the protracted blood work in the lab. It takes the error and guesswork out of diagnosis so the physician can prescribe the appropriate treatment or suitable antibiotics.

The test may also be set up to detect antibodies that are present after a patient has recovered from an infection. Fraunhofer IZM researchers are now focusing on this application to detect earlier infections with the COVID-19 virus, which can help with efforts to trace how the infection has spread. The human body forms molecules or proteins called biomarkers in response to an infection. Capture molecules placed on the surface of the graphene-based sensor to detect these biomarkers. Differential measurements of biomarkers’ concentration determine if an infection is present.

3D structure to enlarge the measuring surface

This sensor platform’s most remarkable feature is its base material: Electrically conductive and biocompatible, graphene oxide is also a very reliable means of detection. To date, it has only been used in microelectronics in its original form, a 2D monolayer. Fraunhofer IZM researchers are now applying it in a 3D structure in form of flakes. This 3D form increases the measuring surface and the accuracy of measurements.

Manuel Bäuscher, scientist at Fraunhofer IZM and sub-project manager at Graph-POC, sees great prospects ahead for these graphene oxide sensors: “We can pivot from the current medical field to also develop in the direction of the point of need; that is, towards environmental technology and the detection of environmental impacts. But of course the corona application is our first priority.” The graphene oxide flakes’ 3D array and heightened sensitivity also open the door to further applications. For example, it could detect harmful gases such as carbon monoxide or acetone even at room temperature. As it stands, these gases have to first be heated to trigger a surface reaction that today’s sensors can detect. The graphene oxide sensor reacts at lower temperatures when metal oxides bond with its sensitive surface.

Fraunhofer IZM researchers are taking on another challenge to scale the production process up for mass manufacturing: They are looking to apply the graphene oxide coating at the wafer level so that hundreds of chips can be processed at once.

Antibodies detectable after coronavirus infections in about one year

The graphene oxide-based sensors have to be integrated into a plastic carrier and the reliability of the system have to be tested before the rapid tests can be deployed. Although the original project to detect infections is slated to run until spring 2021, the researchers do not expect to be able to verify the sensor for the coronavirus for another year yet. The partners in this project are the Charité, Aptarion Biotech AG, Technische Universität Berlin, MicroDiscovery GmbH and alpha-board GmbH. It is funded by the German Federal Ministry of Education and Research (BMBF).

Read the original article on Fraunhofer-Gesellschaft.