Automakers have been using natural fibres for certain automotive parts for decades, including incorporating hemp, sisal and wood into materials for insulation, interior panelling and internal engine covers for luxury cars.

According to Dr Patrick Ehi Imoisili, a postdoctoral researcher at the University of Johannesburg, there are many benefits to producing car parts from renewable sources such as plantain.

“There is a trend of using natural fibre in vehicles. The reason is that natural fibres composites are renewable, low cost and low density. They have high specific strength and stiffness. The manufacturing processes are relatively safe,” he said. “Using car parts made from these composites can reduce the mass of a vehicle. That can result in better fuel efficiency and safety. These components will not rust or corrode like metals. Also, they can be stiff, durable and easily moulded.”

Despite these benefits, natural fibre-reinforced polymer composites are given to cracking, breaking and bending due to low tensile, flexural and impact strength. Car owners sometimes notice effects such as cracking, bending or warping of car components.

Now, Imoisili and his colleagues from the University of Johannesburg have demonstrated that plantain – a starchy type of banana considered a staple food in much of the Southern Hemisphere – could be a promising source for a new composite material for the automotive industry with greater strength than alternatives.

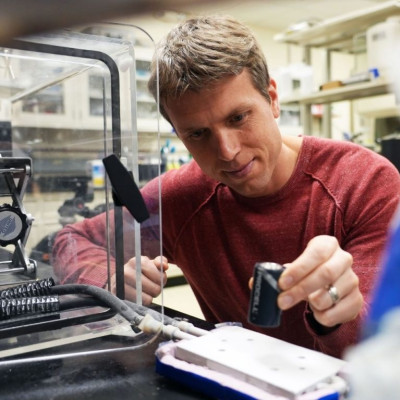

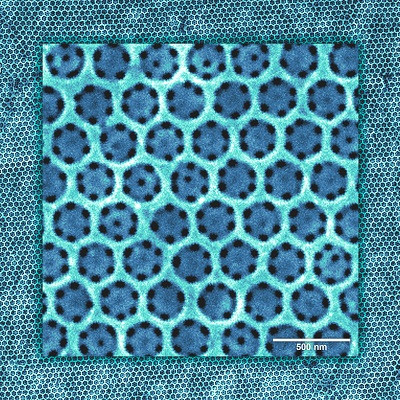

The researchers created a new composite material from epoxy resin, plantain fibres treated to separate them from the stem and improve bonding with the resin (four parts resin to one part plantain), and small mass of carbon nanotubes. The materials were combined in a mould and compressed with a load for 24 hours at room temperature to create a new natural fibre-reinforced polymer hybrid nanocomposite material.

Industrial testing showed that the optimum amount of carbon nanotubes was one per cent by weight, giving the composite material optimal strength and stiffness. Adding carbon nanotubes – compared with epoxy resin alone – also resulted in 31 per cent more tensile and 34 per cent more flexural strength, as well as 52 per cent higher tensile modulus and 29 per cent higher flexural modulus.

“The hybridisation of plantain with multi-walled carbon nanotubes increases the mechanical and thermal strength of the composite,” said Professor Tien-Chien Jen, head of the department of mechanical engineering science at the university and lead researcher. “These increases make the hybrid composite a competitive and alternative material for certain car parts.”

Read the original article on E&T Magazine.