ORF: FIB-SOL is revolutionising the fertiliser industry. How did you arrive at this much-needed solution?

Kavitha Sairam: FIB-SOL is currently developing and commercialising nanofibre-based agricultural inputs. The product is a five-gram fibre that is soluble in water and can be applied on the field using conventional or modern irrigation practices. The product addresses the demand for live bacteria that could rejuvenate the soil. It could also increase the nutrient utilisation efficiency, allowing plants to assimilate nutrients in a better way.

The idea of entrapping agriculturally important microbes came to me a few years ago, when I had just completed my doctorate. I was working on stress signal transduction to improve secondary metabolite production in fungal systems. At that time, I was keen to start my own business pertaining to science and was exploring many ideas, including the development of assays for biomarkers. That is when my PhD guide and mentor Prof. T.S. Chandra insisted that we should develop some technologies to address issues in agriculture.

This is when I started exploring agricultural practices. I found that the soil has lost its nutrient utilisation efficiency, most of which could be attributed to the soil deprivation of microbes. Indiscriminate use of chemicals has reduced the microbial content in the soil. These microbes are essential for the appropriate absorption of plant nutrients. The soil microbes also play an important role in converting organic manure to nitrogen, phosphorus and potassium (or NPK), which the plants need for growth. Hence, I identified that the missing link in both chemical and organic farming is the soil microbe or biofertilisers.

Biofertilisers have been supplied by agricultural universities like Gandhi Krishi Vigyana Kendra (GKVK) for long. However, they are supplied by mixing with inorganic carriers like lignite, peat and talc, which does not support their existence. I realised that a method to stabilise these bacteria will be a solution. There were technologies like freeze drying, but it is very expensive.

Hence, I thought of exploring stress biology, where some stress stabilisers could be added in the bacterial media to stabilise them. Alternatively, electrospinning and encapsulation could be a solution. My junior and co-founder Dr. Anant Raheja was working on nanofibre technology, and we partnered to explore this further. We understood that besides stabilisation we could also increase the payload of cells/unit area using this technology.

This would bring down the bulkiness of the material by reducing the carrier thousand-fold. The advantage offered would be huge savings on logistics for distributors and users. Since the stability of the organism was improved, the efficiency in the field also improved substantially. The other advantage of the technology is that a wide variety of molecules, both organic and inorganic, can be entrapped. Thus, the technology is a versatile platform available for the exploitation of variety of agri inputs. Although some research and development effort will be needed as and when new product pipelines are added, we believe that some day most of agri inputs will be redefined using this technology.

ORF: Tell us how you set up India’s largest in-house production of nanofibres, and how you envision expanding this market further.

KS: Agricultural inputs as a sector has been long ignored and not much research and development has been added, due to low returns on interests associated with it. But improving agri inputs to make them safer and more efficient is necessary. The demand for food will increase with population growth. The soil cannot be eroded constantly of its natural biota. Considering these problems, an alternate solution to redefine agricultural inputs is important.

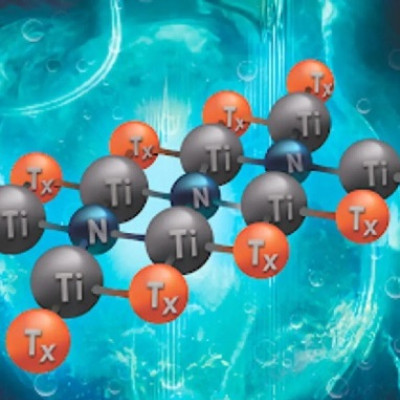

It is in this context that FIB-SOL is trying to offer the most sophisticated technology of stabilising bacteria through a controlled process of electrospinning in nanofibres. Although electrospinning and nanofibre technology existed for the past four decades, it has not been explored on biologicals. In a market like agriculture, where the volumes are huge, there is a need for a technology that can be scaled up. Currently, electrospinning is largely used for making filtration membranes.

At FIB-SOL, we have pivoted it to produce biologicals, with some customisation to the existing methodology. Fib-SOL partnered with engineering companies and had also hired an engineering team internally to focus on the machinery development. The basic parameters needed to produce biological entrapped nanofibres were extrapolated to the large-scale machinery.

Various conditions were optimised and the components needed for the process were built internally and assembled in such a way that we now have the largest scale for water soluble nanofibres in the country.

Apart from indigenous machinery, we have also identified methods to customise industrial scale machinery for the optimal production of our products, removing any production bottlenecks.

ORF: Not only are you deploying a new product, but you are also expanding a whole new agricultural input market segment. What are the changes required at a global scale to accept this paradigm shift?

KS: Agricultural inputs are broadly classified as solids and liquid inputs. Today micro encapsulation technology is widely used to entrap effective microbe consortium to improve soil quality and plant yield. FIB-SOL’s technology is close to this. Nanoparticles are also widely explored, and several products are developed as nanoparticulate formulations. This is a nascent market and the safety of these products must be tested under specific guidelines.

Hence, it is the responsibility of all stakeholders—the government, agricultural institutes, researchers, agricultural startups — in formulating and setting up the new guidelines for nano based formulations. In this context, we are proud to say that FIB-SOL has contributed significantly by registering its inputs for setting up these guidelines. Anant has been actively taking part in the panel discussions on formulating these guidelines and ensuring that our concerns are addressed.

A similar shift is expected to happen globally, since the farming community is aware of the benefits of the new technologies that are currently being developed. Facilitating the usage of such technologies at the ground level will not only increase the benefits to the farmer but will also be a benefit to the environment and society. This is why it is important for all stakeholders to participate in these activities and also educate farmers as well.

ORF: What are your views on India’s strengths in medical and agricultural research, and support systems for early-stage innovation, and what exciting developments should the country pursue?

KS: I believe the country’s potential to innovate in the medical and agricultural fields is huge given the knowledge base. The environment has never been more conducive, with there being many opportunities for the industry and institutes to partner and innovate. Government schemes like BIRAC have been incredibly supportive for researchers to validate and develop their ideas into a commercially viable product. The technology business incubators that are set up across the country ensure that the innovations are provided with all facilities, including research and development, financial and regulatory guidelines. The innovations are nurtured by scientific institutes and startups due to their combined efforts.

In this context, it appears that the future for research in the agricultural and healthcare sectors is currently at its peak and will become more aggressive in the next decade. The support system for early stage innovations is well set and the country will reap its benefits in the coming years.

At the same time, the handholding on the regulatory issues is still a challenge. New products in the agricultural and healthcare system always face regulatory hurdles. Although we need stringent regulations in these sectors, given their importance in human life, it is the responsibility of the government to come up with clear guidelines for these regulations. This will ensure appropriate safety practices as well as an early launch of new technologies for the benefit of the society.

With this platform set, I believe that in the next decade we will see India innovating in various ways in the healthcare and agricultural sectors, and commercialising these successfully.

Read the original article on Observer Research Foundation (ORF).