Carbon nanotubes exhibit remarkable properties such as mechanical strength 100x that of steel at 1/6 the weight and could revolutionize numerous industries.

Unfortunately, existing manufacturing approaches have not adequately lowered the production cost of this game-changing material, preventing mainstream adoption. SkyNano overcame this limitation by creating a manufacturing process that significantly reduces carbon nanotube production costs, resulting in carbon nanotubes that are competitively priced with other conventional carbon structures.

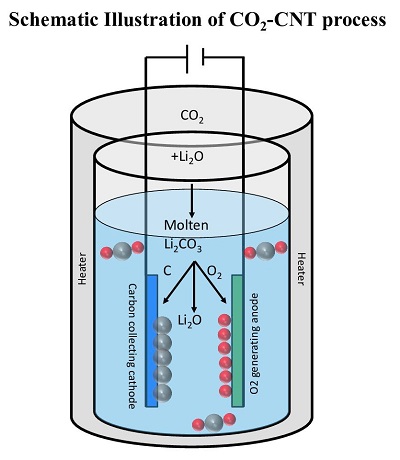

Schematic illustration of CO2-CNT process.

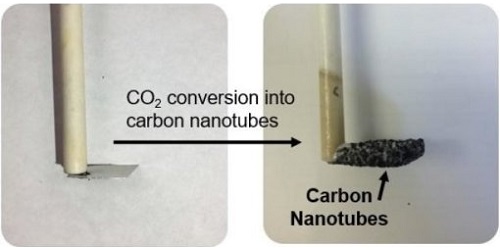

This cost reduction was achieved through a novel process that extracts harmful carbon dioxide from the environment and permanently stores it as solid, stable carbon nanotubes.

The SkyNano manufacturing process, developed with Vanderbilt University, provides advanced carbon materials at cost parity to conventional carbon additives, is CO2 negative, and does not produce harmful carbon byproducts like other carbon nanotube manufacturing approaches.

Using carbon dioxide to make single-walled carbon nanotubes.

Given that carbon nanotubes also have the potential to provide significant energy and CO2 savings when replacing conventional carbon structures, this truly remarkable innovation stands to have a lasting impact.

Read the original article on Research & Development World.