Scientists from TSU, the Institute of Strength Physics and Materials Science of Siberian Branch of the Russian Academy of Sciences (ISPMS SB RAS), and the Engineering Chemical-Technological Center (ECTC) have developed new materials with a bactericidal and virucidal effect that can be used to create various medical products, including protective masks and medical clothing. The materials were tested at the Federal Research Center for Fundamental and Translational Medicine (Novosibirsk) with the most modern protocols for assessing antiviral activity, using a model of the influenza A/H1N1 virus, and tested at the ISPMS SB RAS (Tomsk) in the Escherichia coli model. The new materials have shown high efficacy with both model objects.

"The situation with new pathogens arising from natural foci requires a fundamentally new approach to the organization of prevention: it is necessary to create barriers to the spread of microbes by preventing their accumulation on surfaces and medical products, - explains Aleksey Sazonov, an adviser to the TSU administration. SARS, bird flu, H1N1, and COVID-19 have shown that it is not enough to treat surfaces with disinfectants. The surfaces themselves must fight the infection".

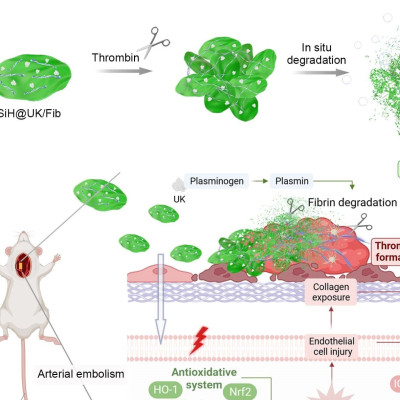

TSU and ISPMS SB RAS scientists have developed new technologies for imparting antiseptic properties to polymeric medical materials, including fibrous ones, used for the manufacture of protective masks, gowns, hats, and other medical items. The scientists used zinc oxide nanoparticles and biocomponent particles of copper oxide (Cu-Fe)O, obtained by the method of the electrical explosion of conductors, as a tool that acts as a barrier to the pathogen.

A liquid containing strains of the pandemic model influenza virus A/Tomsk/273-MA1/2010 (H1N1pdm09) was applied to the materials. After 30 minutes, the researchers assessed the viral load in the swabs. In washes from polypropylene samples containing particles of copper oxide and zinc oxide, there was no viral load, in contrast to the washout from the surface of the control sample (spunbond), where a high virus content was noted.

Along with this, the antiviral activity of materials with nanoparticles was tested on a culture of MDCK cells sensitive to the virus. They were treated with fluids from washes and the cell viability was assessed. The analysis showed that washings from nanomaterials did not hurt cells, in contrast to washings from the control sample (spunbond) that did not contain nanoparticles.

During the studies, the effectiveness of the protective properties of new materials against E.coli was revealed. Along with this, it was found that technological processes do not hurt bioactive particles and do not reduce their protective qualities.

"The test results helped us to take a fresh look at our development, - says Alexander Vorozhtsov, TSU Vice-Rector for Research and Innovation. - The nanoparticles we have obtained are promising for use in other areas. For example, they can be incorporated into paints and varnishes and used for surface treatment in hospitals, schools, kindergartens, and other high-traffic organizations. Now for such purposes, silver-containing paints are sometimes used. Paints with our nanoparticles will not only be effective but also several times cheaper. Thanks to such coatings, the disinfection process will become permanent. At present, TSU and its partners are solving the issues of commercializing a new product and bringing it to the market".

Read the original article on Tomsk State University.