Around 70 million metric tons of hydrogen are produced globally every year for various industrial sectors. These include steel manufacturing, oil refining, metallurgy, food processing, chemical, and fertilizers.

Hydrogen energy is exceptionally versatile as it can be utilized in both liquid and gaseous forms. This gas can be converted into electricity or fuel by adopting different methods.

The amount of hydrogen present in the universe is high compared to any other element. It has been estimated that approximately 90% of all atoms are hydrogen. However, the hydrogen atoms cannot exist independently and have to be decoupled from other elements. Decoupling determines the sustainability of hydrogen energy.

What is Green Hydrogen?

The electrolysis process involves the splitting of water into oxygen and hydrogen in an electrolyzer under the influence of electric current. When the electricity used in the process is generated using a renewable source such as wind or solar energy, the resultant pollutant-free hydrogen is called green hydrogen. Generally, the sun is regarded as the largest and the ultimate renewable energy resource that has been recently used in the production of green hydrogen.

Production of Green Hydrogen Using Nanoparticles

Scientists from the Institut national de la recherche scientifique (INRS) at the University of Quebec have partnered with the Institute of Chemistry and Processes for Energy, Environment and Health (ICPEES) at the CNRS-University of Strasbourg. They have recently made a breakthrough in producing green hydrogen by creating a novel sunlight-photosensitive-nanostructured electrode.

Splitting water molecules into oxygen and hydrogen through electrolysis, industrial electrolyzers commonly demand extremely high energy and require large investments. The team of researchers at INRS and ICPEES were primarily inspired by a natural process known as photosynthesis. The team developed a sophisticated electrode that undergoes photocatalysis to split water molecules under the sun's light.

For the optimized usage of solar energy, scientists have utilized titanium dioxide (TiO2). TiO2 is a chemically stable semiconductor that is easily available and photosensitive to UV-light, about 5% of the solar irradiance.

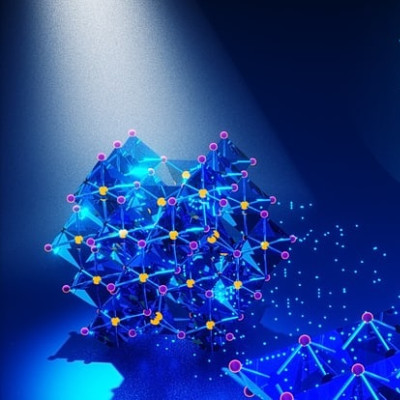

Researchers have modified the atomic composition of TiO2 and enhanced its photosensitivity to visible light. They have successfully developed an electrode that can absorb up to 50% of the sun's light emitted.

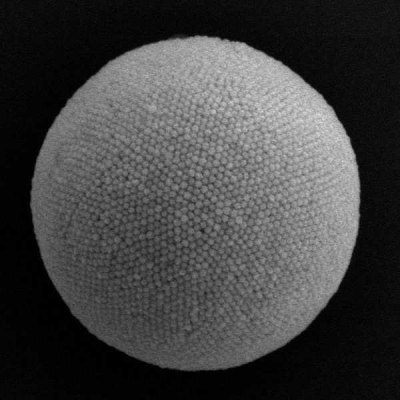

Nanostructuring augments the ratio between the surface and volume of a material. Scientists have created a TiO2 nanostructured electrode, a network of TiO2 nanotubes similar to that of a beehive structure. This nanostructure enhances the operational surface area of the electrode by a factor of 100,000 or more.

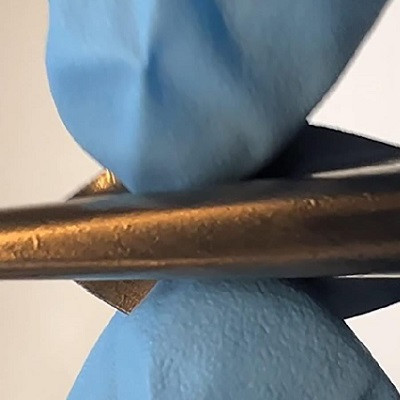

The final step of electrode development is nanodecoration, where researchers deposit catalyst nanoparticles on the TiO2 nanotubes network by the laser ablation deposition technique. This deposition elevates the efficiency of the electrode for the production of green hydrogen.

During electrode development, one challenge was to replace the costly classical catalysts, i.e., iridium and platinum, with a lower-cost catalyst. The research team identified cobalt oxide (CoO) as an effective co-catalyst for electrolysis. They found that CoO nanoparticles can increase the novel nanodecorated electrodes' photocatalytic efficiency tenfold in visible light.

Advantages and Applications of Green Hydrogen

One of the main advantages of green hydrogen is that it can be used in the production site and be transported elsewhere.

Another benefit of green hydrogen is that it can be manufactured wherever there is water and electricity. It can be stored in existing gas pipelines to power household appliances. This nanostructured electrode can work as an independent generator of heat and electricity in the presence of water and energy.

Green hydrogen fuel can supply clean power for transportation, manufacturing units, and many other energy-dependent units. Another significant advantage of the production of green hydrogen is that the byproduct of the process is oxygen.

Challenges of Green Hydrogen

In comparison to natural gas, gasoline, and propane, hydrogen is more flammable in the air. Therefore, handling this requires great vigilance. Hydrogen is less dense than gasoline, and, therefore, it needs additional steps such as lowering its temperature to -253 ˚C to liquefy it or compressing it to 700 times atmospheric pressure before transportation.

The Future of Green Hydrogen

According to Goldman Sachs, green hydrogen could supply up to 25% of the world’s energy needs by 2050. Scientists are working to reduce the cost of green hydrogen production.

A current analysis revealed that if the cost of green hydrogen and its derivatives can be lowered to $2/kg, it will be readily used by multiple sectors such as power generation and steel and fertilizer production. Another form of green hydrogen is green ammonia, a potential replacement for fossil fuels in thermal power generation. Green ammonia can significantly decrease greenhouse gasses and other toxic emissions.

Scientists believe that increasing the production and utilization of green hydrogen will help achieve net-zero emissions by 2050 and dampen the rise in the world’s temperature. Currently, many countries such as Australia, Japan, Germany, and Portugal are involved in developing green hydrogen to minimize the use of fossil fuels.

Read the original article on Azonano.