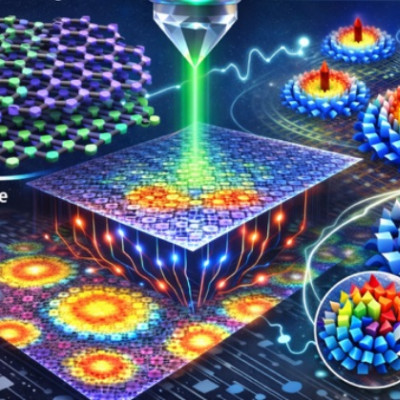

Graphene is a sheet-like two-dimensional carbon material and is nanosized and ultra-thin. This advanced functional material is easy to align uniformly, contributing to its excellent conductivity and its barrier performance.

Applying graphene or blending with other materials makes additional functions possible. To date, Toray has developed technologies to create very thin, top-quality graphene from inexpensive graphite materials.

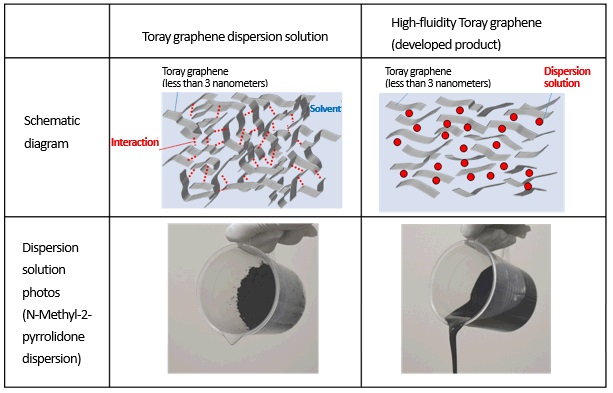

The issue, the company said, is that thinner graphene is more likely to aggregate. In contrast, higher concentrations make graphene more like clay, impeding fluidity, according to Toray.

It is hard to apply and mix graphene in clay form, so it is necessary to dilute and use it in low-concentration solutions, the company said. This has masked the inherent benefits of graphene, Toray noted.

Toray, therefore, developed a dispersion technology to control viscosity by adding a unique polymer material that suppresses aggregation from interactions between graphene.

The result, it said, was a highly concentrated ultra-thin graphene dispersion solution with increased fluidity. According to Toray, the fluidity is excellent, even in high concentrations.

The solution is accordingly easy to handle and apply without dilution and more readily demonstrates its outstanding electrical conductivity and other advantages, the company said.

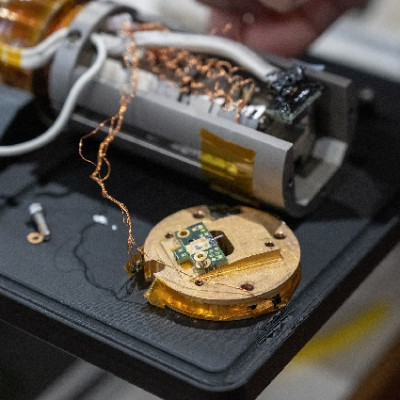

The high dispersibility and ease of mixing make it simple to blend the solution with other materials, Toray noted. A good application with the new solution would be as a conductive material for lithium-ion batteries, Toray suggested.

It can be mixed easily with cathode material, with graphene inserted between cathodes to boost conductivity, according to the company.

This approach lowers capacity losses from conductive pathways degrading during repeated charging and discharging, thereby extending battery life, Toray said.

The high-performance batteries of electric vehicles conventionally employ carbon nanotubes as conductive agents, noted Toray. Toray said testing confirmed that the new solution offers 50% better battery life than carbon nanotubes.

It is also worth noting that applying and drying the solution laminates graphene to form a dense film, the company pointed out. One use of the film could be printable electronics wiring that is highly durable and conductive without rusting like metal.

Diverse other applications could include mixing the solution with anti-corrosion paints to block water and oxygen permeation that causes rust, thereby enhancing durability.

Read the original article on Printed Electronics Now.