Archer Materials Ltd has progressed its graphene-based lab-on-a-chip device (A1 Biochip/biochip) technology development with improved biochip nanofabrication capabilities.

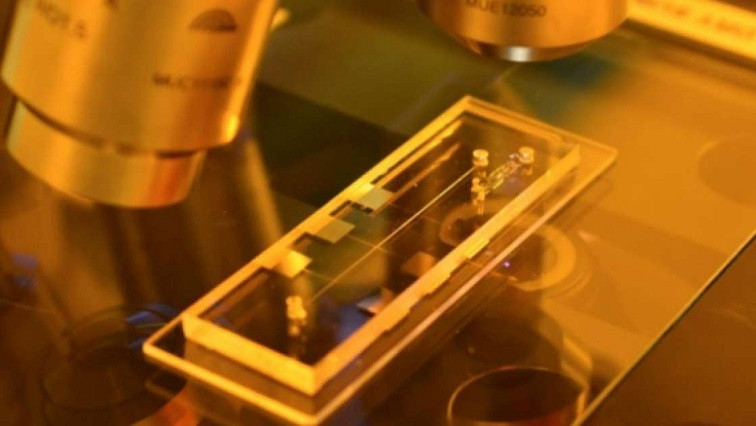

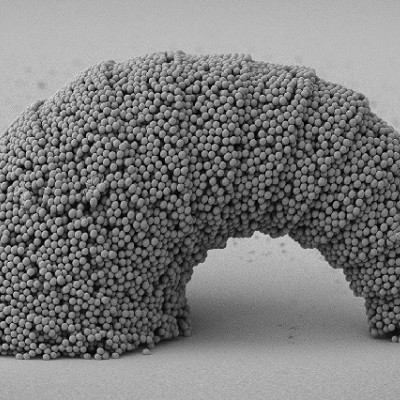

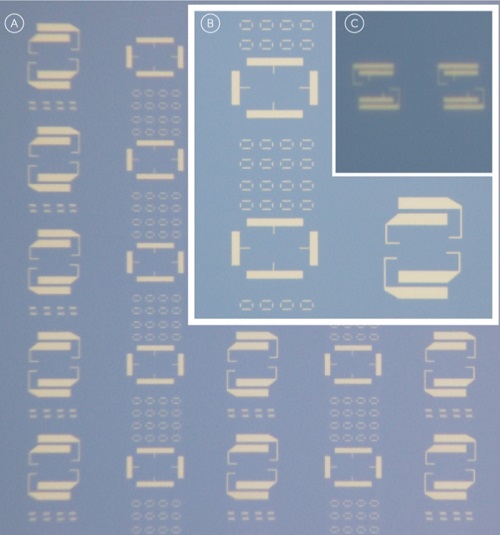

The company has successfully demonstrated that it can fabricate nanosize biosensor components of 100-150 nanometre features on silicon wafers.

Previously using local semiconductor foundry fabrication techniques, the company was limited to one sensor per 1 square centimetre; but with its in-house capability, AXE has now miniaturised key biosensor components to chip-formats on silicon by nanofabrication translating to over 1 million sensor components within 1 square centimetre.

Nanotechnology experts boost capability

Archer Materials has recently brought on permanent staff to pursue areas of highest value-added activities in its biochip development.

The team has grown to include expertise spanning semiconductor device fabrication, nanoscience and technology, advanced materials engineering, and molecular biology.

CEO Dr Mohammad Choucair said: “Archer has attracted talented technologists to work on a promising, potential solution to a global challenge that has significant socio-economic implications.

“As we ramp up our biochip development, we will strategically bridge industry capability gaps, and where possible, locally.

“At Archer, our staff have a proven track record of producing intellectual property that is worth protecting internationally.

“As we solve for significant technological barriers in our biochip development, the company will rapidly translate this knowledge into strong IP assets that would underpin high value, long-term commercialization.”

The company's market cap is approximately A$203.3 million and today shares have been as much as 7.7% higher to A$1.06.

Biochip development and commercialization

Last year, Archer announced its plans to miniaturise key biosensor components of its biochip technology (reducing the size to nanoscale) onto silicon wafers; a technology development milestone required prior to validating commercial advantages of ultra-sensitivity and device integration.

Translating the biochip sensor components onto silicon wafers would also enable high volume chip production – required for any future retail applications of the biochip.

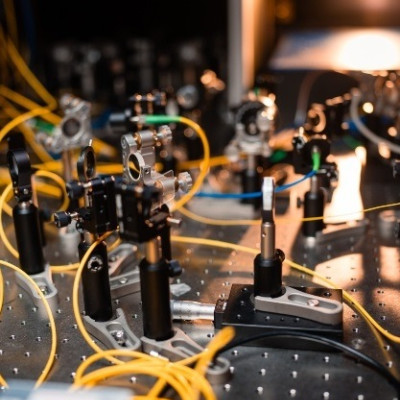

The company is now able to expand on its commercial access-and-use of some of the best instrumentation in the world, utilising more than $150 million of sophisticated chip building facilities in Australia to manufacture its graphene-based biochip technology.

Nanofabricated biochip electrode componentry of a silicon wafer containing patterns of metallic electrodes at various feature sizes down to 100-150 nanometres.

Lab-on-a-chip device potential

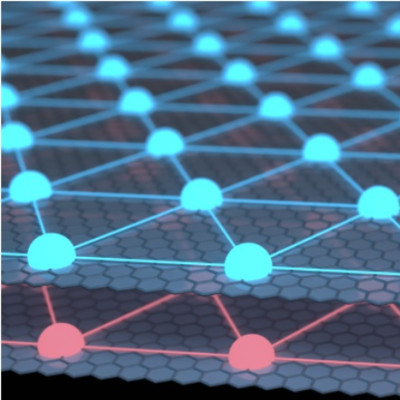

Archer’s biochip design principles involve using proprietary graphene-based materials as integrated circuits, to form the key sensing elements in its lab-on-a-chip technology.

The biochip end-use is initially aimed at addressing the complex detection of diseases affecting the respiratory system.

Lab-on-a-chip devices integrate several biological laboratory functions on a single chip, one being biosensing, and others including sample delivery, for better diagnostics.

The largest technological barriers to commercialising such devices involve nanofabrication that link to high-value advanced manufacturing – which is the current focus of Archer in its biochip development.

Read the original article on Proactive Investors.