Nanostructuring of materials leads to completely new, often surprising properties; this makes them highly interesting for new fields of application and technologies. However, whether these materials can be processed into robust components and thus find their way into applications depends very much on their mechanical properties. These are usually particularly difficult to determine without changing them through the measuring process or even destroying the materials.

A German-French research group led by Patrick Huber (DESY and TU Hamburg) has now developed a non-contact and non-destructive measurement method using laser ultrasound in such a way that the elastic properties of nanostructured materials can be characterised in detail. They report on their research results in the journal Nature Communications.

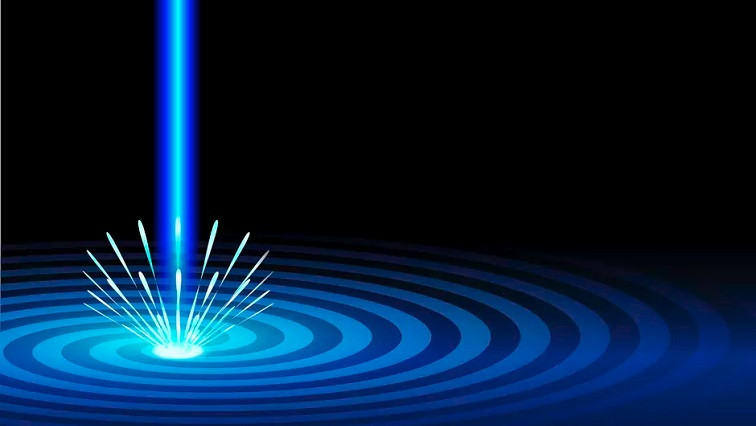

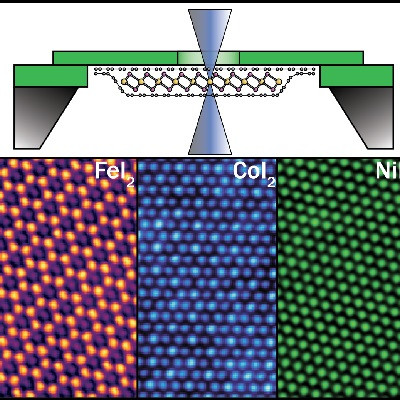

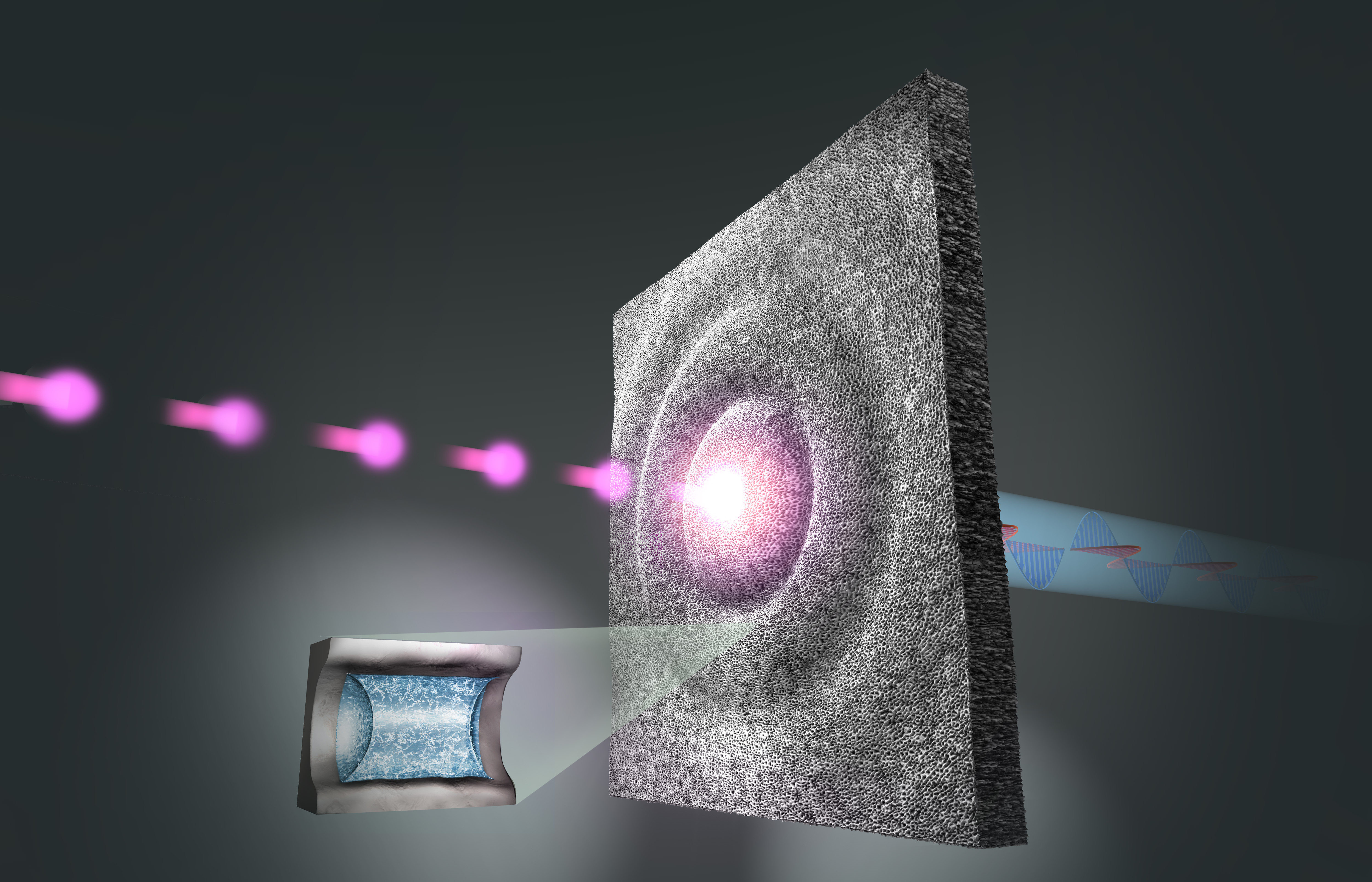

Similar to droplets hitting a water surface, short laser pulses lasting only a fraction of a billionth of a second excite a nanoporous silicon membrane to vibrate in the ultrasound range. The elastic wave propagation in the membrane, whose nanopores are filled with a liquid, is detected interferometrically with a second laser, so that a non-contact and non-destructive mechanical characterization of the hybrid nanomaterial is possible. The membrane illustration is based on electron micrographs of nanoporous silicon with a pore diameter of 7 nanometres.

Materials with nanostructures exhibit many interfaces and extreme geometric limitations. Their interplay leads to new behaviour in many material systems. In particular, nanoporous solids, whose pore space is filled with liquids, have therefore already led to new high-performance materials for energy storage, biosensors and water treatment in recent years. The mechanical properties of such hybrid materials often determine whether they can actually unfold their technological potential. Conversely, many classical mechanical characterization methods are very difficult or impossible to apply to porous or nanostructured material systems, which makes targeted improvement of these properties and thus the technological use of nanomaterials difficult or even impossible.

Now, the Hamburg-Paris research team has succeeded in deciphering the complex mechanical properties of nanoporous materials, especially porous silicon, with the help of laser-ultrasound experiments, thus making them more accessible to a mechanistic understanding and for technological applications.

Patrick Huber, who heads the research group “High-resolution X-ray analytics of materials” at DESY and the Institute for Materials and X-ray Physics at TU Hamburg, explains: “A pulsed UV laser generates thermoelastic oscillations in porous silicon without contact. These oscillations, which are in the ultrasonic range, penetrate the entire monocrystalline material.”

The characteristics of the resulting surface and guided elastic waves in the volume of the material depend to varying degrees on the direction-dependent elastic properties of the nanostructured silicon. A laser interferometer detects these waves from the nanomaterial in a completely contactless manner, so that the mechanics can be derived with the help of a suitable model for elastic waves. The complex signal analysis and the development of this model were carried out in collaboration with Parisian scientists. “In particular, Nicolas Bochud´s creative ideas for modelling ultrasound propagation were invaluable to the success of the measurement method,” says Huber. Bochud is an associate professor at the MSME laboratory in Créteil (France).

Marc Thelen, first author of the study and doctoral student in Huber's research group, explains: “Conventional ultrasound measurements have the disadvantage that the sample must be in direct mechanical contact with the ultrasound transmitters and receivers. This is done by applying a liquid coupling agent. Porous materials absorb these coupling liquids, so that classical ultrasound experiments are falsified. In contrast, we were able to study empty and liquid-filled silicon and thus demonstrate that the mechanical behaviour of porous materials functionalised with liquids can also be analysed with ultrasound in detail.”

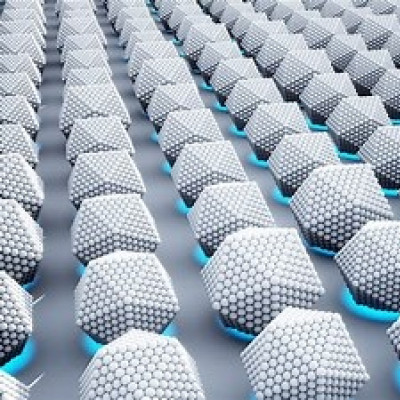

The nanostructured silicon samples investigated contained parallel nanopores that had formed in a self-organised manner and had a density of 100 billion per square centimetre of cross-section. The experiments showed clear differences to the behaviour of conventional silicon single crystals, as they are known as wafers from the semiconductor industry. “On the one hand, we were able to demonstrate that the high nanoporosity causes a significant reduction in stiffness. However, it also leads to the fact that the direction-dependent elasticity present in the silicon crystal seems to be significantly cancelled out. Surprisingly, we were also able to detect a slight change in the diameter (conicity) of the tubular pores on the nanoscale,” explains Claire Prada, Director of Research at the Institut Langevin (Paris), who coordinated this German-French collaboration together with Huber.

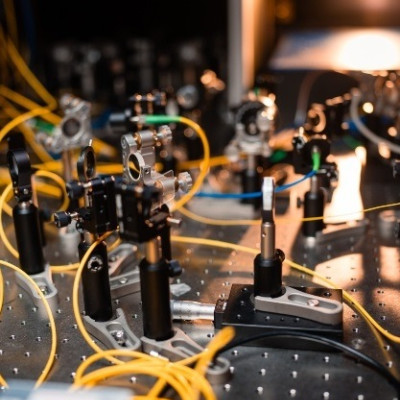

The study shows that recent breakthroughs in laser ultrasound technology open up completely new possibilities for non-destructive and non-contact mechanical characterization and function monitoring of porous materials. Within the framework of this collaboration, it is now planned to combine such laser-ultrasound investigations with other measurement methods, in particular X-ray analysis, for example at PETRA III, in order to investigate not only the mechanical properties but also the interplay of structure, dynamics and function of nanomaterials, as well as the properties of liquids in nanopores in-situ and in-operando.

Read the original article on Deutsches Elektronen-Synchrotron DESY.