As Australia’s national COVID-19 vaccine rollout continues and the threat of new and existing global variants looms, rapid testing remains essential for identification, contact tracing and containment of infection.

Our research team, with the support of our Australian collaborators, are close to completing a year-long quest to develop commercial quantities of locally sourced magnetic nanoparticles – a key missing ingredient to a fully Australian-made COVID-19 test kit.

While antibody tests can show which people have already been exposed and have developed an immune response, polymerase chain reaction (PCR) tests (used at most Australian testing centres) are the gold standard for determining whether a person is currently infected.

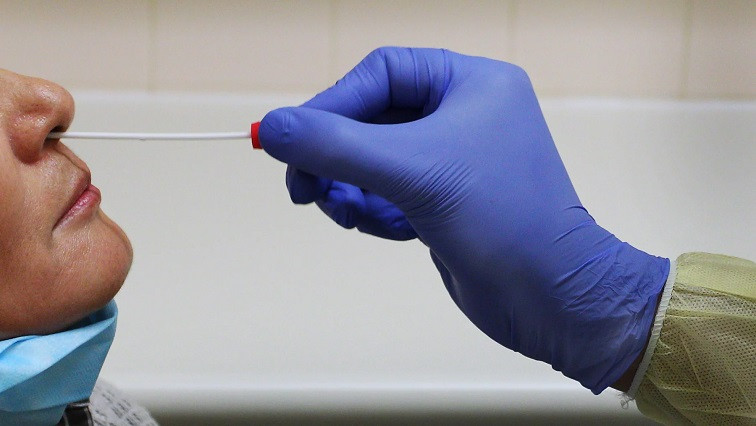

Many Australians, and indeed many people worldwide, will be familiar with the COVID-19 ‘swab test’. A cotton tip is first wiped around the back of your throat and then inserted deep into both nostrils – an odd and unpleasant sensation.

Rapid testing is essential for identification, contact tracing and containment of COVID-19 infection.

COVID Tests: Behind the Scenes

The part you don’t see then happens is in the laboratory, where technicians analyse the sample for RNA – the genetic material of SARS-CoV-2 – the COVID-19-causing virus.

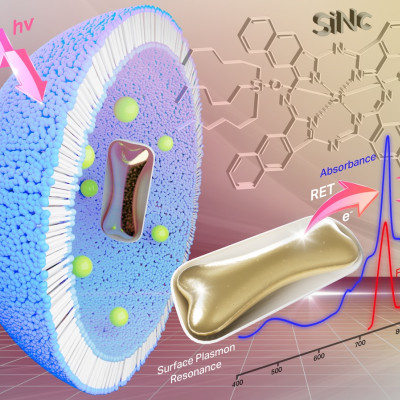

A critical part of this laboratory process is separating the genetic material (known as nucleic acid) from the other biological material collected on the swab. This is achieved using magnetic silica nanoparticles.

These nanoparticles are typically only a few hundred nanometres in size (a millionth of a millimetre) and consist of a core of magnetic material coated in a thin shell of silica (glass), which are added to a vial containing the swab solution.

A special salt is added which causes all of the nucleic acids from the swab to reversibly stick to the silica shell.

Because the nanoparticles are magnetic, the nucleic acids can now be collected and separated from all other unwanted biomaterials in the swab using a simple magnet.

The purified nucleic acids are then unbound from the magnetic silica nanoparticles, and a PCR test is conducted to check if any SARS-CoV-2 virus RNA is present.

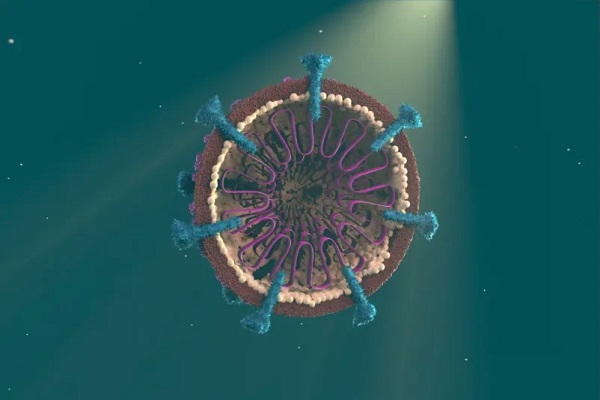

A model of the Sars-CoV-2 virus in cross-section showing its ’spikes’ in blue and its Ribonucleic acid (RNA) in purple.

The Missing Ingredient

When the pandemic struck, however, magnetic silica nanoparticles were not being produced in Australia, and as there are still no local producers, Australian test kit manufacturers are required to source them from overseas.

The vastly increased global demand for these particles has driven costs up, disrupting supply chains, and limiting the availability of magnetic beads to Australian swab test kit manufacturers.

The Australian Government established a COVID Test Kit Task Force, which in March 2020, requested the help of our Nanoscience Laboratory to help produce magnetic silica particles locally, building a guaranteed supply for at least 100,000 COVID tests per week.

But there were a few problems.

Firstly, commercial particles are produced overseas via proprietary methods that are not publicly available, so before we could create an Australian supply, we would need to come up with our own method to produce functioning magnetic silica nanoparticles.

Fortunately, at the ARC Centre of Excellence in Exciton Science, we have been working on making magnetic nanoparticles for other applications including quantum dot synthesis, so we were able to quickly design and test methods for making an appropriate product.

Local Production during a Pandemic

The second problem was that it was 2020, and we were in Melbourne. With the severe restrictions on movement in place for most of the year, almost all staff and students were unable to attend the University’s Parkville campus.

However, our small team of researchers were given permission to occupy space in the largely deserted School of Chemistry to meet this important challenge. The final problem was one of scale.

Each test kit requires approximately five micrograms of silica particles, and so to meet 100,000 tests per week, our initial goal was to make 500 grams of magnetic nanoparticles per week.

We had the chemical know-how, but for a research lab that’s used to making small reactions and producing less than a gram of product, we didn’t have access to all of the necessary equipment.

To get an idea of how big this problem was, imagine being told to make enough pasta sauce for a thousand people – in your home kitchen.

To achieve this massive increase in scale, we set up collaborations with several Australian companies including Scaled Organics in Melbourne, who made available their pilot reactors to produce the amounts of material we required.

Sydney-based COVID test kit manufacturer Genetic Signatures were then able to verify whether each batch of nanoparticles was fit for purpose in a real COVID test situation.

We also had the support of the Monash Centre for Electron Microscopy and the Australian Synchrotron for work to image commercial samples of the nanoparticles and compare them to our test batches.

A Simple Recipe

The reaction needed to be simple and with relatively few steps, in order to minimise costs and other barriers to scalability.

Over months of long hours and round-the-clock work, we identified, optimised, verified and scaled up a synthesis of silica-coated magnetic nanoparticles. But there was a hitch.

We noticed a change in colour of the nanoparticle samples shortly after synthesis, prompting speculation that the crystal structure of the nanoparticles was altering from magnetite (Fe₃O₄) to maghemite (Fe₂O₃) over time.

Recognising the importance of the project, the Australian Nuclear Science and Technology Organisation (ANSTO) gave us priority access to their in-demand equipment, an X-Ray Absorbance Spectroscopy (XAS) beamline at the Australian Synchrotron, to solve this question.

It is not easy to distinguish the two crystal structures as they are very similar, but X-ray absorption spectroscopy can readily tell them apart. From the results, we determined that one of the salts that we were adding to the reaction mixture was driving the formation of one crystal structure and not the other (these results will be published at a later date).

We were then able to find the optimal salt concentration to produce magnetite, which is preferable as it’s more magnetic than maghemite, and functions better within the finished nanoparticles.

Towards an Australian-Made Test

To develop a product capable of matching equivalent overseas commercial offerings, we have run over 500 experiments with small batches to optimise each element of the production, including the thickness of the silica coating, the reagent ratios and concentrations, and even different purification methods.

Subject to verification in clinical tests, our nanoparticles could soon be used to supply magnetic silica nanoparticles for an Australian-made COVID-19 test kit – as we continue to rise to the challenges of this unprecedented global health emergency.

Read the original article on The University of Melbourne.