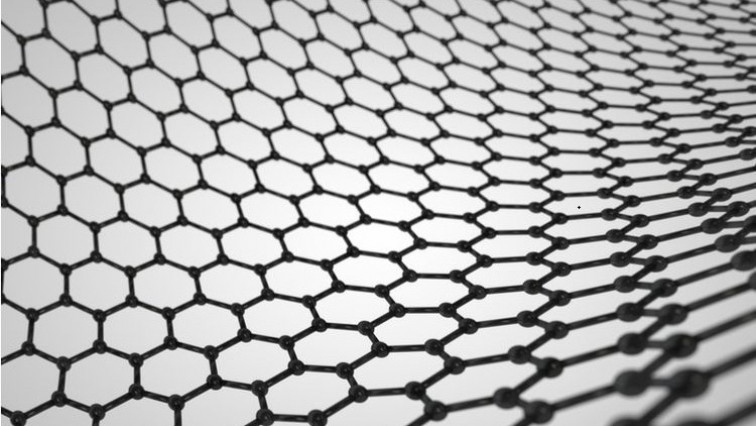

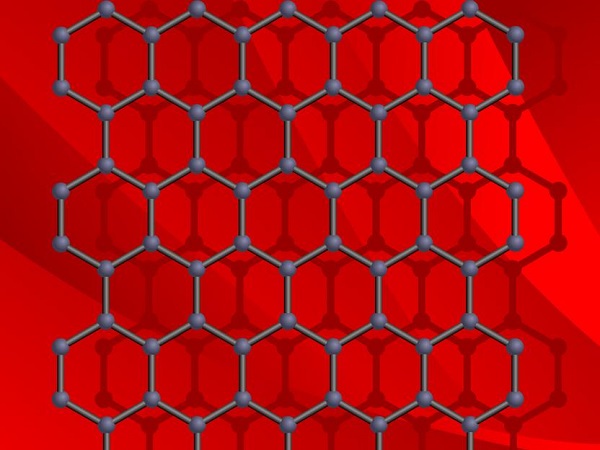

Graphene is considered the nanomaterial of the future: it is the thinnest two-dimensional material in the world, is stronger than steel, conducts electricity and heat well, can be easily chemically modified and has unique optical properties. Because of these qualities, graphene could be used in many industries - from batteries for electric cars, to microchips and solar cells, to fighting viruses in medical technology.

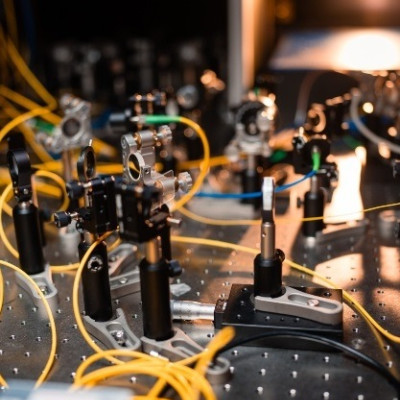

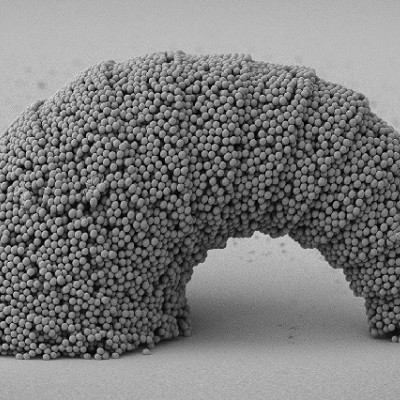

However, commercial use of graphene has been difficult so far because there are no standardized methods that reliably determine the structure and composition of the nanomaterial and its derivatives. Companies can therefore not be sure whether their products really meet the desired requirements. In the ISO-G-SCoPe project, BAM is working together with European partners from industry and science to develop a method for the reliable chemical characterisation of graphene and graphene oxide. BAM can draw on its many years of experience in the field of chemical analysis of nanomaterials using surface-sensitive methods and electron microscopy.

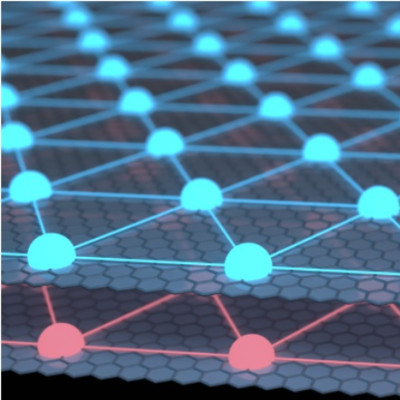

As part of the project, new methods are being developed for the precise measurement of the lateral and vertical size of graphene and graphene oxide flakes. This involves determining how many layers are present and what the flake size distribution is in different batches. Chemical analysis will determine the amount of oxygen present in graphene oxide and the material will be examined for impurities and functionalisation. In addition, two VAMAS (Versailles Project on Advanced Materials and Standards) round robin tests are being initiated under the direction of BAM in order to validate the processes in a worldwide test and develop them into standards.

"If we can establish standardised characterisation procedures for graphene, we will support industry in moving innovations more quickly from the laboratory to large-scale production," says Dr. Jörg Radnik, head of the project at BAM. "And we create confidence in the quality and safety of the material."

Read the original article on LUMITOS AG.