“We found that the mechanism of polymerization is the same in both cases, but the kinetics of polymerization differs significantly. The reactivity of the monomer in solution turned out to be about five times lower than in the melt, which is most likely due to the effect of solvation – the interaction of the solvent with the solute,” says Galukhin.

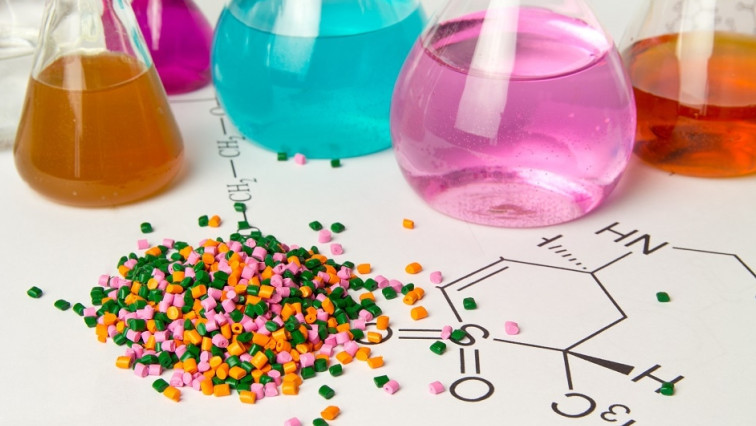

PhD candidate Ilya Nikolaev, whose upcoming thesis is dedicated to the dependencies between the structure of aryl cyanates and their reactivity, adds, “When heated, aryl cyanates enter into a polymerization reaction, the kinetics of which we are studying. In this publication, we examined the effect of a high-boiling solvent (diphenyl sulfone) on the kinetics of polymerization of the monomer we synthesized. Polymerization in a solvent medium makes it possible to obtain promising nanoporous polymer materials. Such materials can be used to store, for instance, hydrogen.”

According to Dr. Galukhin, one of the main technological problems of hydrogen energy is the storage of this very light and explosive gas. Getting into a porous material, which is a good adsorbent, gas molecules “stick” to its walls, and if the surface area of these walls is large, then the material can “absorb” a significant amount of gas. Since hydrogen is very light, it fits very little into cylinders, which means that storing this gas in this way is ineffective. If a nanoporous material is placed in a container, then it will absorb gas like a sponge, and as a result, much more of it will fit into the storage system.

A new generation of adsorbent is also needed for eliminating oil spills on water and for creating various sensors, and new scientific results can be used to optimize the conditions for obtaining such materials based on aryl cyanate monomers.

Read the original article on Kazan Federal University.