Graphene nanotubes ensure compliance with international ESD safety standards for personal protective equipment at automotive, electronics, and ATEX facilities.

Nanotubes outperform competing anti-static solutions in all elements of uninterrupted grounding chain of industrial wear, including gloves, clothing, and footwear.

Ultra-low dosage of nanotubes provides stable anti-static properties and makes it possible to maintain standard material processing and final product color flexibility.

Automotive, electronics manufacturing, oil and gas, chemical, medical, even flour-milling facilities—all require the use of personal protective equipment (PPE) with anti-static properties. Beyond protection of workers from ignition risk, the use of anti-static clothing prevents the failure of static-sensitive devices that can lead to large financial losses. Further growth of the PPE market is driven by new safety regulations aimed at keeping pace with the increasing automation of industrial facilities.

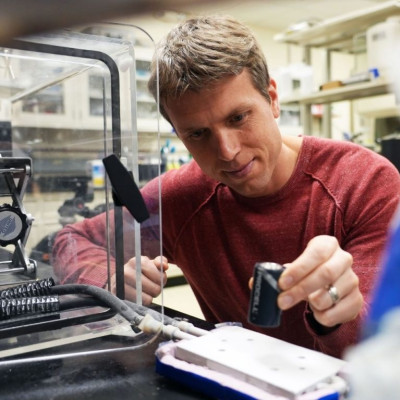

Latex gloves with graphene nanotubes

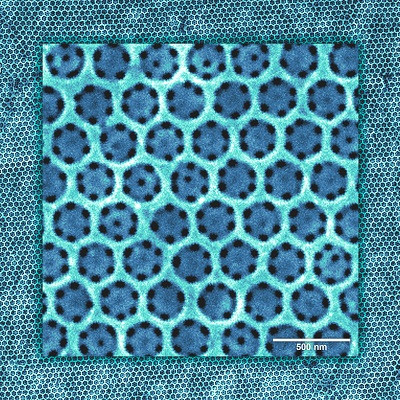

Graphene nanotubes, applied as an advanced conductive material, are being rapidly adopted by the growing PPE market. The world’s largest graphene nanotube manufacturer OCSiAl has developed a multitude of solutions for protective wear applications, from safety suits shielding the body from extreme temperatures and flames to anti-static shoes and clean room gloves.

Thanks to their high strength, electrical conductivity, and flexibility, the working dosage of graphene nanotubes is 10-40 times lower than that of other solutions. A content of just 0.05-0.06% graphene nanotubes makes it possible to produce anti-static latex gloves with electrical resistance of 10^7 Ω. In contrast to ammonium salts, which are easily evaporated, nanotubes grant permanent and humidity-independent resistance in full compliance with the new European standard EN 16350:2014 and ATEX regulations. The anti-static properties of these gloves also allow for smooth operation of touchscreens without the gloves having to be removed to ensure worker and product protection.

Besides all types of latexes, graphene nanotubes are being applied in the silicone, fluoroelastomer, and PVC plastisol-based textile coatings used for workers’ ESD protection against aggressive fuels, chemicals, hot temperatures, and sparks to ensure they match the global standards for protective wear. One remarkable example is fireproof and anti-static clothing designed for protection against sparks, splashes of molten metal, high temperatures, and risk of sudden electrostatic discharge. In this application, anti-static metal yarn has been replaced with graphene nanotubes, giving anti-static properties to the fabrics at the fluoroorganic treatment stage. Nanotube technology has proven effective after 15 washes, demonstrating uniform anti-static protection throughout the product, with electrical resistance of 10^7 Ω.

To ensure proper grounding, polyurethane elastomer with graphene nanotubes is used in the outsole and midsole of footwear, enabling anti-static shoes to be used in various static-sensitive facilities in the chemistry, oil and gas, electronics, and mining industries.

The use of graphene nanotubes grants a unique combination of permanent anti-static properties with original production processing and color saturation of the product—a combination that is difficult to achieve with other conductive solutions. A tiny dosage of nanotubes facilitates the creation of safer, longer lasting, colorful clothing and contributes to the global sustainable consumption approach thanks to the use of less raw materials to obtain better performing products.

Read the original article on Industry Today.