Roads, buildings that line motorways and cars that zoom down the streets could all unlock a greener, more efficient future with the wonder material graphene, which thanks to a UAE-UK partnership is being rapidly introduced around the world.

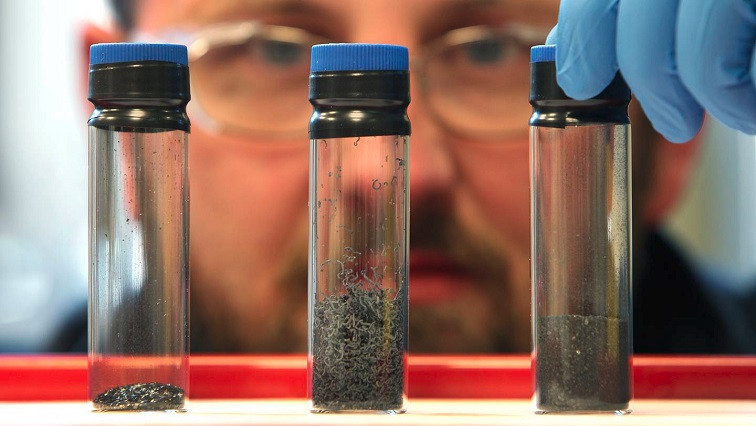

In the UAE over the coming months scientists from Graphene@Manchester are conducting some initial potential test pours over roads, parks and even sports venues.

Led by chief executive James Baker, the company is working with Abu Dhabi to progress the commercialisation of graphene and its material applications.

"If I look 100 years ahead ... not only do I get smarter, lighter concrete [through graphene], I build sensors into my concrete that enable it to tell me when it needs replacing or is damaged."

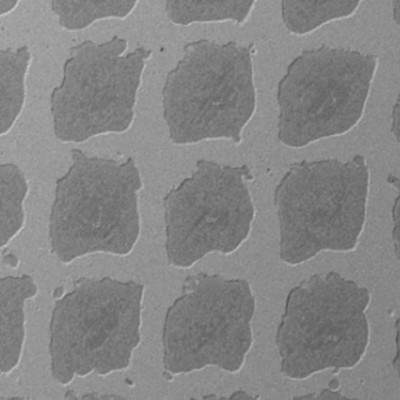

One hundred million times smaller than a single human hair, graphene is simultaneously the world's strongest, thinnest and most lightweight material.

For a single substance to lay claim to these competing accolades seems a physical impossibility: like having one protoplasm for a butterfly and a lion.

And if this was not remarkable enough, graphene is also the best conductor of heat and electricity known to man, and capable of near uniform absorption of light.

Its remarkable properties were recognised by the UAE in 2014 when Abu Dhabi clean technology and renewable energy group Masdar contributed £30 million ($39.47m) to a graphene institute in Manchester, UK.

The north-west English city has been the unofficial home of the graphene industry since 2004 after University of Manchester scientists isolated the single-layer atom, not with the help of some newfangled piece of sci-fi wizardry but simply good old sticky tape.

This was nearly 20 years ago and, despite graphene's discoverers winning the 2010 Nobel Prize in Physics, the incredibly small and strong material remains as little spotted as it is known – the Marvel superhero equivalent of Ant-Man.

Harnessing graphene's superpowers

As most of the Marvel fanbase would attest, having great power is one thing, knowing what to do with it is quite another.

Years-long gestation of a product from discovery to mass use is completely normal, however, Mr Baker told The National.

"It can take years to develop into products and applications," he said.

Mr Baker's team developed a process they christened "fail fast and learn", although even with this speedy protocol, a web of testing regulations slowed things down before products were brought to market.

"How do you make the graphene? How would you mix it? How did you formulate it so that you get the performance you need? Every time, each time, you make it? And it sounds simple, but trust me, there are different graphenes made from different methodologies with different properties. And they don't always mix the same."

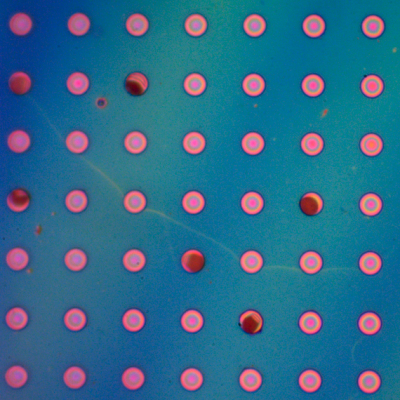

Graphene will first make its mark with "tip of the iceberg" concrete mixes that promise strong environmental benefits.

"Working with industry and working with partners we've done over 800 tonnes of concrete using 30 per cent less material, also using no steel reinforcement," Mr Baker said. "It cures quicker, it has no cracks ... and [it's] one of the areas we are talking about with our colleagues in Abu Dhabi about how we might do something similar over in the UAE."

Graphene's sustainable impact

One of the most gnarly challenges of the world's drive to reduce emissions is doing so while also providing the social, economic and physical infrastructure needed to meet the needs of today.

A material that allows for much more energy-efficient construction could be transformative in this regard and, unsurprisingly, Mr Baker agrees.

"Concrete produces 10 per cent of global CO2, so if I can reduce this by 30 per cent, that alone would reduce global CO2 by 2 per cent to 3 per cent."

He also envisages graphene-made concrete – known as concretene – playing a massive role in future smart cities, such as Abu Dhabi's Masdar City, which the UK's Prince Charles visited late last year.

It is already being used in real-world applications in Manchester, including a gym and campus at the university, and as part of the Mayfield regeneration, which includes homes, offices and leisure spaces.

Graphene@Manchester is currently doing floors while it awaits the data to approve full structural elements such as high-rise buildings and bridges.

Should this transpire, the days of graphene being an abstruse compound will be numbered.

Graphene a perfect match for the UAE

In hot and humid environments like the UAE's, "where the temperature's different, the water's different, the materials are different", construction can be bedevilled by environmental challenges. Graphene concrete could alleviate these.

"With graphene we actually get the full 28-day performance within 12 hours," Mr Baker said. "You could be laying the concrete on the first day and building on it on day two."

"When I came out to Abu Dhabi two years ago to sustainability week in January 2020, we had quite a lot of interest but what I talked about was potential," he said. "I think Abu Dhabi invested in potential, but we're now starting to translate that potential into real investment and market opportunities.

"We've now done over 350 projects, we've got a number of partners, and we're really starting to see an acceleration of these products and applications in the marketplace."

Following Iron Man's demise in Avengers: Endgame, perhaps the franchise should replace him with a new, all together more robust – and environmentally friendly – superhero: Graphene Man. You read it first in The National.

Read the original article on The National.