In April, the team published its results on food-grade nylon film and single-use coffee cups lined with low-density polyethylene. In the case of the coffee cups, the particles were not pure polyethylene, says Christopher Zangmeister, an aerosol scientist at NIST who led the work. “The material is oxidized slightly, we think, during its journey from the factory to the cup and from the cup to the hot water,” he says. “It shows the complex chemistry that these sorts of nanomaterials and thin films can undergo in their short life span.”

Tiny plastic particles are not just released from disposable coffee cups and nylon films used in food packaging and commercial kitchens. Microplastics, typically less than 5 mm in diameter, and nanoplastics, less than 1 µm in diameter, seem to be everywhere scientists look: in water, food, and air and in human blood, lung tissue, and stool. But what their presence means for human health and the environment is still unclear.

Regulators are struggling to evaluate microplastics’ risks because the particles have complex compositions and variable sizes and shapes. Exposure data are limited, and toxicology studies typically use particles that do not reflect what’s in the environment. Researchers are just beginning to identify the sources and compositions of microplastics to conduct the toxicity studies needed to understand the effects of real-life exposure.

Why characterization matters

Most of the toxicology studies on microplastics published so far have used polystyrene beads. Such beads are easy to purchase in different sizes and with various functional groups, but they are not representative of microplastics that scientists are finding in the environment.

“From a shape point of view, that is absolutely not what we are seeing in the electron microscope” when looking at water samples collected from marine and freshwater environments, says Christie Sayes, a professor of environmental science at Baylor University. It’s also not what Sayes sees when her lab makes microplastic particles by pulverizing plastic cutlery into an ultrafine powder in a stainless steel blender.

Over the past 1½ years, Sayes has been collaborating with researchers at the US Environmental Protection Agency in Cincinnati to analyze microplastic particles in water samples. The particles in those samples, as well as in those made in her lab, “tend to be jagged, sharp-sided fragments with pointed edges,” she says. Most microplastic particles in air are also fragments, not spheres, says Stephanie Wright, an environmental toxicologist at Imperial College London.

Composition is another challenge. Researchers have detected polystyrene in water samples, but many other polymers, including polyethylene, polypropylene, and polyamide, are also abundant. And microplastics rarely start as a pristine polymer. They also contain plasticizers, pigments, and metals, according to Sayes.

In addition, one of the ways microplastics get into the environment is from ultraviolet weathering of plastic debris into smaller and smaller fragments over time, Wright says. “That UV weathering process can change the chemistry” of the plastic, at least in laboratory experiments, she says. Materials can become less hydrophobic and coated by biomolecules, minerals, and metals, she says. These contaminants can change a particle’s properties, such as its charge or polarity, she notes.More than a decade ago, researchers learned that engineered nanomaterials’ physical and chemical properties, including size, shape, surface chemistry, and charge, affect how they interact with cells. The same appears to be true for micro- and nanoplastics, toxicologists say.

Some of the first evidence that the shape and length of nanomaterials affect their toxicity was published in a groundbreaking in vivo study in 2008 that showed that long, stiff, fibrous carbon nanotubes can elicit the same pathological response in mice as asbestos.

That was an extreme example to prove a specific toxicological hypothesis, says Martin Clift, a professor of particle and fiber toxicology at Swansea University Medical School in the UK. He recalls an experiment he conducted several years ago with colleagues at Helmholtz Zentrum München that also revealed that shape is not the only factor in nanoparticle toxicity. “We looked at triangles versus hexagons, with spheres as a control,” Clift says.

The researchers saw that the differently shaped gold nanoparticles interacted with cells similarly. “But when you started to look at mechanistic pathways associated with inflammation, oxidative stress, and cell death, those with the greater number of edges showed the greatest toxicology,” Clift says. In this experiment, what was on the particle surface and the number of edges were factors, according to Clift. It’s a combination of physical-chemical properties and how those elements interact with cells and tissues that drives the biological effect for any engineered nanomaterial, he says.

One of the findings from nanotoxicology that continues to surprise some researchers is the importance of what’s attached to particles’ surfaces. As long as the particle material doesn’t dissolve, “what seems to really matter is what’s on the surface,” says Vicki Colvin, a Brown University chemistry professor with expertise in nanomaterials. For microplastics, “it doesn’t really matter what flavor of polymer might be inside,” she says. The polymer type might, however, control how small a particle gets and how it weathers, Colvin says.

From nanotoxicology, researchers learned that attaching amine groups to particle surfaces can elicit a stronger adverse biological response than attaching other chemical moieties, such as carboxylated groups, Clift says. Negatively charged surfaces also appear to be less toxic than positively charged surfaces, he says.

Making microplastics

Researchers are starting to fabricate micro- and nanoplastic particles in the lab for toxicology studies so they can move beyond polystyrene beads and simulate more real-world exposure scenarios.

“They might be using a ball mill, stainless steel vials, or metal ball bearings,” which could introduce metal contamination and complicate toxicology studies, Wright says. And toxic organic contaminants in the environment, like flame retardants and phthalates, may have a high affinity for the material, she adds.

Nanotoxicology taught researchers that the presence of endotoxins and soluble impurities like iron can affect how cells respond to particles, Wright says. “If you’re looking at things like inflammation or oxidative stress, it’s really important that you know exactly what you’re putting on your cell before you decide it’s the plastic” causing an effect, she says.

Most people characterize their microplastic particles according to size, Wright says. They might have some scanning electron microscopy images, size distribution in culture medium, and Fourier transform infrared or Raman spectra to show the particles are polymers, she says. But characterizing impurities, such as metals, organics, and endotoxins, is not really done yet, she says.

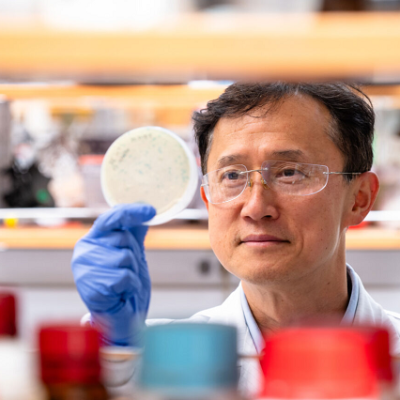

“We don’t want to replicate the mistakes we made with nanotoxicology 10–15 years ago,” says Philip Demokritou, the Henry Rutgers Chair in Nanoscience and Environmental Bioengineering at Rutgers University and an adjunct professor at Harvard University’s T.H. Chan School of Public Health. People rushed to buy commercially available engineered nanoparticles for toxicity studies, he says. Impurities and batch-to-batch variability made it difficult to compare results across studies, he says.

In an effort to better control the properties of nanomaterials used in toxicology studies and to understand more real-world exposures, Demokritou established a center for nanosafety research at Harvard in 2016. The US National Institute of Environmental Health Sciences, which is part of the National Institutes of Health, provided funding to establish the center.

The center has been at the forefront of research on emerging engineered nanomaterials’ interactions with biological systems and their potential health implications, says Demokritou, who is still the center’s director. It also serves as a reference source of nanomaterials, including metal oxides, carbon nanotubes, graphene, nanocellulose, and advanced nanocomposite materials. Researchers in the US and the European Union use the nanomaterials in toxicology studies, Demokritou says. “We make them in a controlled way, make sure there are no impurities, and store them in controlled conditions,” he says. “That enables us to have some reproducibility in our bioactivity data.”

Demokritou is now developing a similar program for microplastics. He and his collaborators are making micro- and nanoplastic particles that are more environmentally relevant than polystyrene beads. They use incineration to thermally degrade polyethylene pellets at 850 °C into particles that are then fractionated by size and extracted into water. They also make polyamide powder by milling sheets of polyamide with a high-speed cryogenic rotary mill. And they weather polyamide fibers, like those in nylon clothing, by washing them and exposing them to UV light and drying them.

The researchers chose the polymers on the basis of their abundance. Manufacturers produce millions of metric tons of polyethylene, polyamide, and other polymers annually.

“Our goal is to develop a kind of a reference microplastics library that we can use for our studies,” Demokritou says. “We want to discover the fundamental rules of bioactivity—how the structure or properties of materials affect health outcomes,” he says. “In order to do that, you need to have a way to control properties. Otherwise, we’re not going to help the risk assessors to answer the question of health implications.”

Potential health hazards

People are exposed to microplastics primarily from ingesting particles in food and water, as well as inhaling particles in air. Using in vitro systems that simulate digestion or inhalation, scientists are starting to build a picture of how micro- and nanoplastic particles can harm human gut and lung cells.

“You won’t be able to test these gazillion combinations of micro- and nanoplastics with animals. That would require a lot of money and time,” Demokritou says. “You have to start with the physiologically relevant in vitro approaches and in silico computational toxicology approaches” to get an idea about bioactivity, he says. Materials that are shown to initiate molecular events associated with negative health effects can then be studied further in laboratory animals, he says.

Demokritou and colleagues are using an in vitro model of the epithelium small-intestinal to test whether micro- and nanoplastics interfere with the digestion and absorption of nutrients. The epithelium lines the digestive system.

“We did confirm that there are interactions with the absorption of fat in a negative way,” Demokritou says. Microplastic particles ingested with fatty foods can double the bioavailability of that fat, he adds. Microplastics also affect the absorption of micronutrients, such as vitamins, he says. “We haven’t done animal studies, but the fact that we’ve seen this in vitro is kind of alarming,” Demokritou says.

In vitro studies also suggest that the presence of micro- and nanoplastics in food and water can lead to a disorder known as leaky gut, in which material escapes the digestive tract and interacts directly with other tissues rather than having the intestinal lining as a filter, Demokritou says. Researchers need to conduct animal studies to confirm these preliminary findings, Demokritou adds. “It’s an emerging area and we really need to get to the bottom of this.”

Sayes and her colleagues at Baylor screen microplastic particles in water samples collected by the EPA and the plastic particles they fabricate in their lab for toxicity to human gut cells. Their gut-on-a-chip test system incorporates intestinal epithelial cells to look for cell viability, macrophages for particle uptake, and immune cells for immune responses.

The researchers separate the particles by size—greater than 100 µm, 1–100 µm, and less than 1 µm. They then expose each group to the gut-on-a-chip system, as well as to three strains of bacteria that are environmentally relevant and part of the human gut, Sayes explains.

The results have yet to be published, but in general, the 1–100 µm particles decreased the viability of the intestinal epithelial cells and decreased the growth of the three bacteria, Sayes says. But bacterial growth increased in the presence of larger particles, she says.

Sayes speculates that the bacteria could be using the larger microplastics as a nutrient source. Another possibility is that the larger microplastics could have more bacteria on their surfaces than the smaller ones do, she says.

Clift and Wright are collaborating to study how inhaled microplastics affect human health. “We aerosolize well-characterized micro- and nanoplastic particles through a commercially available aerosol chamber and deposit them onto our advanced in vitro cultures of the lower lung to start to understand their potential human health hazard,” Clift says.

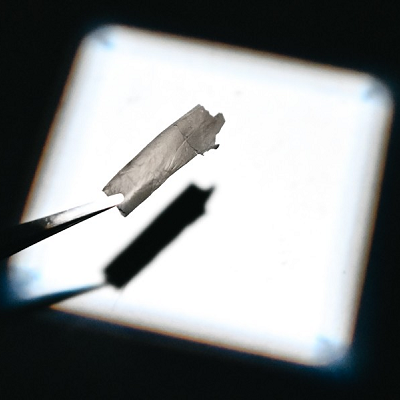

Wright’s group makes microplastic particles by manually grinding frozen plastic powders, such as polyamide and polyethylene, in a ceramic mortar and pestle. The researchers also collect air samples from indoor environments, such as their university’s gym, to better understand real-world exposures. Wright presented some preliminary results from the gym study at the Society of Toxicology annual meeting in late March. The work has yet to be published, but Wright says they found high levels of microplastics in the samples from the gym. Using Raman spectroscopy, they identified most of the particles as polyamides, likely from nylon sports apparel.

Researchers are just starting to conduct mechanistic toxicology studies to understand how microplastic particles behave in cellular systems. Ultimately, they hope the work will be used to develop models to help design safer materials in the future. “If we want to avoid adverse health outcomes, we need to know what we need to avoid or what properties to look out for,” Wright says.

Changing behavior

Once researchers understand how microplastic particles behave in cellular systems, they can create models of toxicity, says Andrew Maynard, a professor and director of the Risk Innovation Lab at Arizona State University. When a manufacturer produces a new type of plastic that releases a subtly different type of microplastic, “we can plug those characteristics into our models” and get a risk profile of that new material, he says.

Maynard says that while scientists and funding agencies might get excited about microplastics over the next 2–3 years and spend billions of dollars to research the health implications, he’s concerned that “10 years from now, nothing will have changed and nobody will be talking about it.”

That is what happened with engineered nanomaterials, he says. The reason no one in the mainstream media is talking about nanomaterials’ toxicity today is because there was a disconnect between “people building their careers on the assumption that nanomaterials are very dangerous” and translating that research into public policy or regulatory action, Maynard says. Researchers are still getting large grants to study the toxicity of nanomaterials, “but in the real world, nobody cares,” he says.

“It would be great if people were asking smart research questions and that translated into changes in behavior in society,” Maynard says. “Whether it’s how we manufacture things, how we use things, or how we assess risks versus benefits.”

In contrast to Maynard, Brown University’s Colvin believes nanotoxicology research did have an impact on the nanotechnology industry. Once scientists raised nanomaterials’ potential environmental, health, and safety implications, industry slowed down and shifted gears to avoid negative consequences, she says.

In the case of microplastics, the consequences are still unknown. But regulators could target large sources, such as polyethylene terephthalate, which is used to make soda and water bottles, Colvin says. That would force industry to investigate alternative materials that may break down through different pathways and not lead to sturdy, persistent small particles in the environment, she says.

The situation with microplastics has many similarities with what “we were talking about 10–15 years ago with nanomaterials,” Maynard says. “And there’s actually an opportunity to get the conversation right this time,” he says. But Maynard is not optimistic that regulators will address all the relevant properties of microplastics.

“We were arguing a decade or so ago that we’ve got to look at what’s physiologically important,” whether that’s size, shape, surface chemistry, surface area, or just the number of particles, Maynard says. But many regulations are still based on “the mass of material that gets into the environment or what you’re exposed to,” he says.

Such an approach is not science based, “because it tells you nothing about the mechanisms of how these things cause harm,” he says. “But it is a very, very crude way of keeping concentrations low enough that you don’t see significant or substantial harm.”

The US Food and Drug Administration, for example, sets limits on the total mass of a polymer allowed to migrate from food packaging, Zangmeister says. All the samples he and his colleagues at NIST measured, including disposable coffee cups, released masses of plastic particles well below the FDA regulatory limits. But the particles were 30–100 nm, a size that may have health effects that don’t arise from particles of larger diameters, Zangmeister says, emphasizing “may.” “Methods of regulation on a per-mass basis might not capture all the health effects that may be present in these sorts of materials,” he adds.

And the lack of exposure data makes it difficult to assess the risks of micro- and nanoplastic particles. “We don’t know what people are being exposed to in terms of levels,” Clift says. Risk is a function of both hazard and exposure.

Demokritou is convinced people are getting exposed. Micro- and nanoplastics are everywhere, he says. “And the exposures will go up because we have 6 billion metric tons of plastic already out there that is constantly degrading,” and industry is putting more than 400 million metric tons of plastic out there every year, he says.

Funding for projects to fill in the data gaps is scarce, particularly in the US, according to Demokritou. “We really need to launch a micro- and nanoplastic safety consortium similar to what we did with nanomaterials and bring a lot of groups and scientists together to address these fundamental questions,” he says. “Because right now, with a little bit of funding here and a little bit there, we won’t be able to generate the data that risk assessors need,” he says.

“Agencies should be funding research into how the specific forms of microplastics lead to specific risks,” Maynard says. “We need mechanistic research that ties shape, size, and chemistry into what gets into the environment, where it goes, and what it does when it gets there.”

The global chemical industry also wants answers about microplastics’ health risks. And it is not waiting for government agencies to fund the work. According to the American Chemistry Council (ACC), which represents chemical manufacturers, industry has launched its own microplastics research program.

Details about that program are scarce. But in a statement to C&EN, John Norman, senior director of regulatory and scientific affairs at the ACC, says the “program has funded work to develop standardized sampling protocols and testing materials, examine environmental fate and potential routes of exposure of microplastics, identify potential hazards of microplastics, and develop a risk assessment framework capable of integrating the complex information developed.” Researchers will present the results at upcoming scientific conferences and technical workshops as the data become available, he says.

Read the original article on American Chemical Society (ACS).