Transition metal nitrides coating materials, especially titanium nitride (TiN) coatings, exhibit high hardness, chemistry inertness, excellent wear and corrosion resistance. These properties enable them to serve as superior protective coatings on nuclear reactor structure materials. However, the extreme radiation environment in nuclear reactors may change their properties and degrade their performance. Thus, it is essential to conduct research on the radiation response of the coating materials.

Researchers at IMP have studied the radiation-induced changes in the properties of TiN-based coating materials. They selected TiAlN as an isostructure model material to investigate the irradiation induced nanohardness and microstructure evolution, and the relationship between them.

In the experiment, the coatings were deposited on WFeNi substrate via the cathodic arc ion plating method, and the average grain sizes of as-deposited coatings were about 10 nm. The nitride (N) ion irradiation experiments of the obtained TiAlN coatings were performed at the 320 kV multi-discipline research platform with various temperatures and fluences.

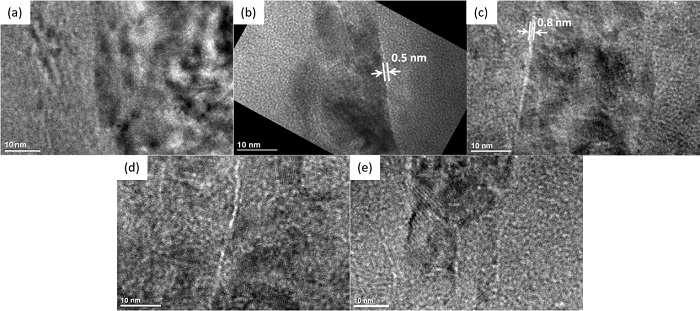

According to the researchers, there is no amorphization or phase transformation observed in each of the irradiated samples, even under the damage level of 10 dpa at room temperature and higher temperatures, indicating that the prepared TiAlN coating has a good irradiation resistance.

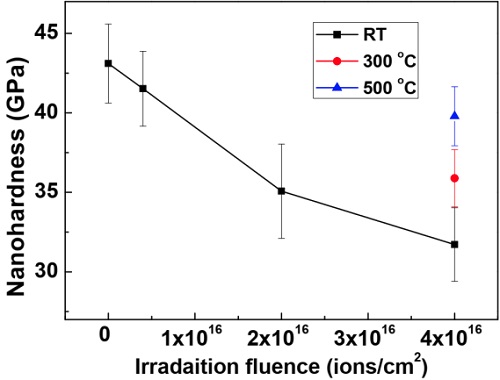

Moreover, they observed significant radiation-induced softening (RIS) effects in all the irradiated samples. The RIS effects were amplified in samples irradiated at room temperature compared with the samples irradiated at the high temperature. The researchers observed a large number of N bubbles in all irradiated samples, and found that the N bubbles located along grain boundaries should be responsible for RIS effects in nano-structured TiAlN coating.

Figure 1. The nanohardness values of TiAlN coatings before and after irradiation.

Figure 2. High resolution transmission electron microscopy images of as-deposited coating (a), RT-2E16 (b) RT-4E16 (c), 300 oC-4E16 (d), 500 oC-4E16 (e) coating samples.

This work was supported by the National Natural Science Foundation of China, the Natural Science Foundation of Guangdong Province and the Advanced Energy Science and Technology Guangdong Laboratory.

Read the original article on Chinese Academy of Sciences (CAS).