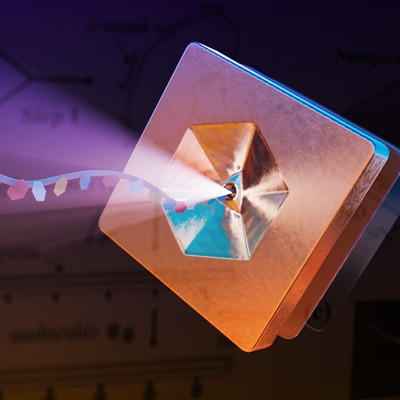

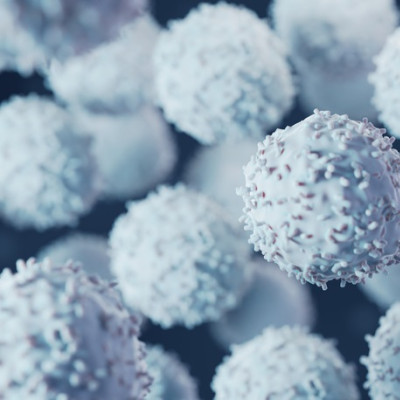

The IJM NanoScaler system is designed for lipid nanoparticle R&D - allowing scientists to determine the optimal process parameters for the formulation of API-containing lipid nanoparticles. These active pharmaceutical ingredients include complex or delicate API like RNA, mRNA, siRNA, and DNA-based molecules, or products that need specific entry into target cells.

Equipped with Knauer’s lipid nanoparticle producing Impingement Jets Mixing (IJM) technology the NanoScaler allows researchers to optimise encapsulation conditions for their nucleotide-based therapy before scaling up the process to run on a larger GMP-compliant IJM NanoProducer unit.

The IJM NanoScaler is made for low sample consumption so as not to waste valuable API. Its small footprint means it can comfortably sit on the benchtop of a research and development lab.

The system comes with five different Knauer Impingement Jets Mixers to help researchers determine which conditions result in the optimum level of API encapsulation. In addition, researchers can use their own custom mixing unit and benefit from the flexibility of the system set-up.

The formulation process can be remotely controlled by software; ran from a conventional PC or laptop, or even a tablet.

The IJM NanoScaler enables the scouting of several key parameters during the lipid nanoparticle encapsulation stage: mixing unit geometries; mixing flow rates and ratios; varying lipid formulations; dilution protocols.

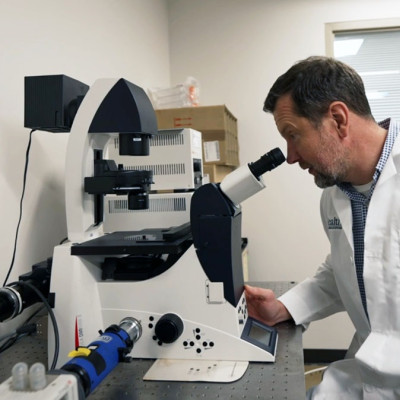

The IJM NanoScaler can be used to produce lipid-encapsulated API at a range from 1 mL to hundreds of millilitres meaning the system is perfect for proof-of-concept testing and process optimisation, pre-clinical trials e.g. for in vitro studies, as well as small-scale production.

Read the original article on Labmate Online.