The results of the first international comparison of the measurement of graphene have been published in 2D Materials, led by NPL, through the Versailles Project on Advanced Materials and Standards (VAMAS) and in collaboration with institutes from around the world.

The international interlaboratory comparison (ILC) outlined improvements that reduce measurement uncertainty, in some cases by a factor of 15, and which will be the basis for a new international standard which is currently under development within ISO/IEC for Raman spectroscopy. This will provide a verified source of data and ultimately provide more accurate and precise measurement standards for the global graphene industry.

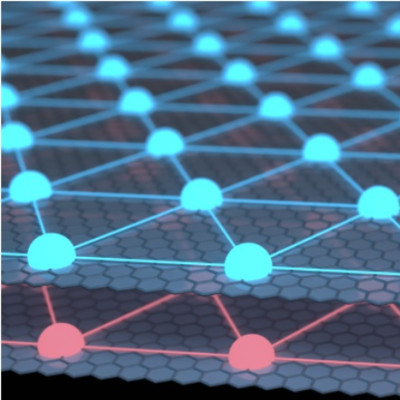

Although a wonder material with many superlative properties set to disrupt industries ranging from electronics to construction, as a single layer of carbon atoms, graphene can be difficult to measure. There is a pressing need for reliable, reproducible and accurate measurements of graphene’s properties, through international standards, to facilitate industrial growth.

Processes such as chemical vapour deposition (CVD) allow companies around the world to now produce graphene on the scale of metres, but a standardised measurement method to determine the quality of the material is still under development within the International Organization for Standardization (ISO) and International Electrotechnical Commission (IEC).

VAMAS was established in 1982 by the G7 group of nations to ensure best practice plus accurate and precise standardised measurement methods, in order to promote and grow world trade. More recently in 2016, a technical working area was established for ‘Graphene and Related 2D Materials’, that now has 14 active projects.

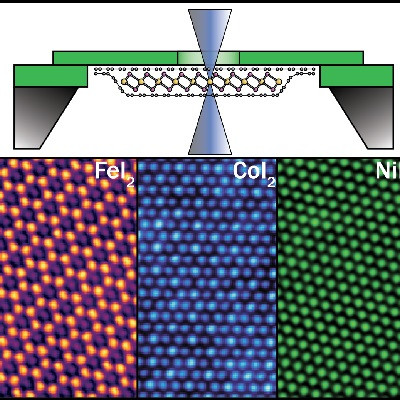

The first of these projects is the measurement of CVD grown graphene using Raman spectroscopy, a go-to measurement technique for understanding the structure of graphene related 2D materials. The Industrialisation Work Package (WP19) of the EU Graphene Flagship funded NPL’s work to lead this international ILC consisting of 17 entities, including National Metrology Institutes, Universities and industry, with CVD grown graphene samples supplied by Graphenea Semiconductor, Spain.

The protocol for this ILC was based on the Raman spectroscopy measurement of CVD grown graphene first published in the NPL Good Practice Guide 145 ‘Characterisation of the structure of graphene’, which was developed in collaboration with the University of Manchester, UK. As well as the first published VAMAS study on graphene, this work was also the first completed VAMAS study investigating the uncertainties in Raman spectroscopy measurements.

By comparing the differences in the measurements of the same CVD grown graphene using the same protocol across many institutes, it was found that important measurands such as the Raman peak intensity ratios used to determine the material properties of graphene, could vary by a factor of 3. However, by users performing an intensity calibration using a certified reference material, this variation could be drastically reduced. Similarly, by using a consistent form of data analysis, the difference in the measured Raman peak widths could be reduced by orders of magnitude.

These results and method improvements will be used within ISO/AWI TS 21356-2 ‘Structural characterization of graphene — Part 2: Chemical vapour deposition (CVD) grown graphene’, which is currently under development within ISO and IEC. As the first VAMAS project within ‘Graphene and Related 2D Materials’, there are further projects addressing the measurement needs of different forms of graphene and using different techniques.

Many of the measurements for these VAMAS ILCs have been completed, however there are several projects that have been recently initiated and are looking for participants. These projects will also contribute to other international standards, ultimately improving the accuracy of the measurement of graphene and other 2D materials and, in doing so enabling industry around the world.

Dr. Andrew J Pollard, Principal Research Scientist at NPL said: “Interlaboratory comparisons are vital if we are to provide a quantitative uncertainty alongside our measured values, as well as help us to improve standardised protocols to achieve the most accurate and precise values possible. These in-depth studies require both time and international collaboration but will help the whole community through reproducible and comparable measurements.”

Prof. Cinzia Casiraghi, Professor of Nanoscience at the University of Manchester said: “Raman spectroscopy is one of the most used techniques for characterization of graphene because it can quickly provide a wide range of information on the quality of this material. Despite its simplicity, discrepancies in the Raman measurements and data were reported in the literature, hence affecting industrial production and the ability to compare graphene samples produced in different labs. The VAMAS project is a first crucial step in the development of a standardised protocol for the characterization of graphene using Raman spectroscopy.”

Dr. Amaia Zurutuza, Scientific Director at Graphenea Semiconductor said: “This was our first time participating in an international interlaboratory comparison, we found the experience very positive and we would like to highlight the crucial importance of these type of studies. It was incredible that such disparate values were obtained on the same samples. We will definitely participate in another ILC in the near future.”

Read the original article on National Physical Laboratory (NPL).