Fortner, associate professor of chemical and environmental engineering, leads one of the few labs in the U.S. investigating the intersection between materials science and environmental engineering. There, materials synthesized directly in the lab, whether magnetic nanoparticles, graphene-based composites, or hyperthermic catalysts, are carefully engineered to treat contaminants in water sources.

Fortner has always been drawn towards improving public health through environmental-based pathways. He initially considered a career in medicine when he first discovered the field of environmental engineering.

“I took a bioremediation course and I became fascinated with engineering biological systems to break down contaminants in situ,” Fortner said.

At the time, traditional environmental engineering research focused on using microbes – biological organisms on the microscopic scale – to degrade contaminants within industrial wastewater streams. After taking courses that bridged his biological focus with applied engineering systems, Fortner found his ‘fit’ and soon switched to environmental engineering.

Though ubiquitous today, nanomaterial research is a relatively new field. In the late 20th century, the development of advanced imaging technologies enabled scientists to study nanomaterials for the first time. In 1989, 15 years after the term “nanoscience” was coined, the first nanotechnology company began to commercialize nanostructures. By 2001, when Fortner entered graduate school, nanomaterials had been industrialized in computer science and biomedical engineering.

Compared to their larger counterparts, nanomaterials have advantages, such as tunability and/or unique reactivity, stemming from their incredibly small sizes and novel properties. As Fortner puts it, “nanomaterials have the potential to do what traditional materials simply can’t.”

In 1985, chemists at Rice discovered a new carbon allotrope - buckminsterfullerene (termed fullerenes or “buckyballs”) - leading them to a 1996 Nobel Prize in Chemistry and sparking a nanotechnology boom at Rice and beyond. Through this, the Center for Biological and Environmental Nanotechnology, an NSF-funded research center, was founded at Rice when Fortner started his graduate studies. There, he worked with collaborators to understand the behavior of nanomaterials in the environment, with his Ph.D. thesis focused on fullerenes in natural systems. At the time, very little was known about the matter that led to several exciting findings underpinning the emerging field of environmental nanotechnology.

"At the time, there was so much to explore,” Fortner said. “Beyond understanding fundamental nanomaterial behavior in the environment, it was clear that there were fantastic opportunities to apply ‘nano’ to critical environmental problems in sensing and treatment (pollution remediation)…to help make folks' lives healthier through a better, cleaner environment.”

Soon after graduation, Fortner joined the faculty at Washington University in St. Louis where he studied the fundamental mechanisms involved with nanostructure synthesis and reactivity. He was particularly interested in understanding how nanoparticles degrade contaminants differently than traditional systems and if nanoparticles have applications beyond the water industry.

During his time at Washington University, he was a Fellow within the International Center for Energy, Environment, and Sustainability, where he collaborated with other researchers to develop nanotechnologies for a range of applications including new water treatment membranes and sensing technologies.

“It was a wonderful place to start an independent research career,” Fortner said. “I developed amazing collaborations there, which pushed me even more to the fundamental side of chemistry and material science.”

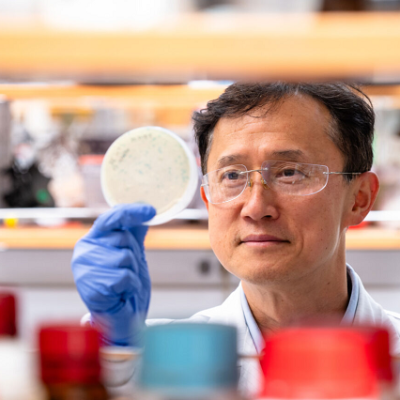

Fortner joined the faculty of Yale’s Department of Chemical and Environmental Engineering in 2019. In the Fortner Lab, almost everything is created from scratch: researchers design and synthesize nanoparticles, multi-component composites, and associated functional coatings to address water-related environmental issues.

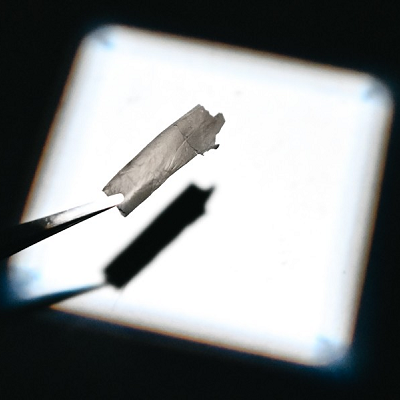

One of his most recent collaborations centers around perfluoroalkyl contaminants (PFAS), which are fluorinated carbon structures found in numerous consumer products ranging from fast food wrappers to Teflon pans to firefighting foams. Because these products were engineered to be unreactive to most chemicals or high temperatures, PFAS contaminants cannot be treated using conventional biological treatment processes. To address these ‘forever chemicals,’ Fortner’s lab, working with Kurt Pennell from Brown University and Natalie Capiro from Auburn University, has engineered superparamagnetic nanoparticles, which are specially coated with sorbents. They discovered that when these engineered nanoparticles are dispersed in a polluted source, contaminants are attracted to specified functional groups on the molecule. The particles, along with the contaminants, can then be collected using a magnet field and the concentrated PFAS can be removed. This strategy allows for very large volumes of media to be managed in a targeted and energy-efficient manner.

“It's amazing,” Fortner said. “We can sorb a significant amount of PFAS onto one particle and simply use a magnet to remove it. It's a nice way to go ‘fishing’ to remove PFAS, or other contaminants, from a polluted water source."

Read the original article on Yale University.