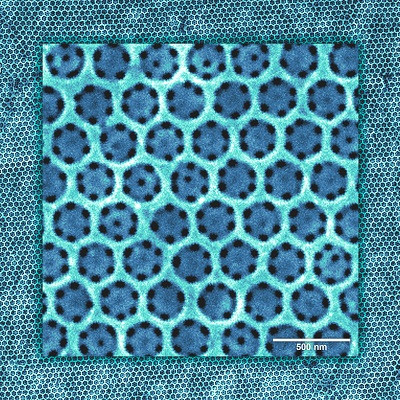

Over the next three years, the two companies will work together to incorporate Levidian’s sustainable graphene in a range of composite materials. Levidian uses plasma chemistry to crack methane into hydrogen and graphene. This process means their graphene has no batch-to-batch variation, a very small number of layers, and a positive environmental impact. The addition of graphene to composite materials and components will lead to improved process times while augmenting physical properties.

The JDA will focus on the unique properties of graphene allowing innovative processing methods and applications in advanced composites. Together the companies will develop fabrics, pre-preg, resin, adhesives, and coatings that address the challenges faced today in various industries including automotive, aerospace and space, and wind energy.

Adamant Composites is a developer of high-end solutions serving primarily the aerospace, defense and energy markets. It has completed projects for several institutional and industrial clients such as the European Space Agency, Airbus, and others. It designs large deployable structures and uses composite and nano-enabled materials in applications such as batteries, hydrogen storage tanks, UAVs airframes, deployable structure subsystems, structural components and ground support equipment for satellites and launchers. Adamant has established pilot lines and processing know-how for nano-enabling composites materials and together with its customers and partners it validates and scales them up for commercial production.

Read the original article on Graphene Info.