Since antiquity, humans have used pigments to add colour to their surroundings. Today the main one is titanium dioxide — a naturally occurring compound that is extremely white and bright in its powdered form. Originally introduced as a safer alternative to white lead pigments, titanium dioxide is now used in most other coloured paints due to its vibrant light-scattering properties.

After the introduction of mass-production techniques early in the 20th century, titanium dioxide has found hundreds of new applications, such as imparting whiteness to paper, plastics, inks, food additives and cosmetics. In its ultrafine form, titanium dioxide is transparent rather than white, but it still retains the ability to absorb ultraviolet light. These properties have seen titanium dioxide nanoparticles being used in sunscreens, solar cells and pollution-fighting photocatalysts.

A handful of companies churn out more than 7 million tonnes of titanium dioxide each year, but disruptions triggered by the COVID-19 pandemic, changes in consumer behaviour, and increasingly strict environmental regulations are threatening future growth. “While the demand for paint is increasing worldwide, the print market is declining because of electronic technologies,” notes Yasushi Nakao, a researcher at Ishihara Sangyo Kaisha Ltd (ISK), Japan’s leading manufacturer of titanium dioxide. “The production of titanium dioxide requires large amounts of energy, which is an issue we must address. For example, we’re reducing our reliance on coal for electricity generation.”

Founded in 1920, ISK boasts one of the world’s most advanced facilities for producing titanium dioxide. While many manufacturers generate titanium dioxide only using technology based on sulfuric acid, ISK is the sole dual-process holder in Japan capable of utilizing a newer method known as the chloride process. “This approach is more environmentally friendly because we can recycle the chlorine gas needed to separate titanium dioxide from its ores,” explains Yoichi Ishibai, another research scientist at ISK. Furthermore, having two production methods enables ISK to generate two distinct crystal structures of titanium dioxide with unique optical and chemical properties.

Made to order

ISK’s commitment to innovation is clear when it comes to titanium dioxide pigments. Because different applications have special performance demands — automotive paints differ from typical house paints — researchers at ISK have developed new chemical and physical techniques that allow them to tailor pigment properties. For example, customers are increasingly requesting paints that are highly resistant to degradation by sunlight or humidity, notes Ishibai. To achieve this goal, ISK uses surface-treatment technology to coat titanium dioxide with thin layers of other oxides, including silicon, aluminum and zinc oxides.

“We can easily modify pigment surfaces with uniform coatings of silicon dioxide, for example,” says Ishibai. “This encapsulates each titanium dioxide particle to improve its weather resistance.”

ISK’s modification capacity, combined with technology for controlling particle size also offers clients the ability to create ‘heat shield paints’ that specifically reflect infrared light, and ‘white conductive paints’ that minimize static electricity in semiconductor clean rooms.

In all cases, the properties of pigments can be adjusted by selecting specific crystal structures using the dual-process production facility.

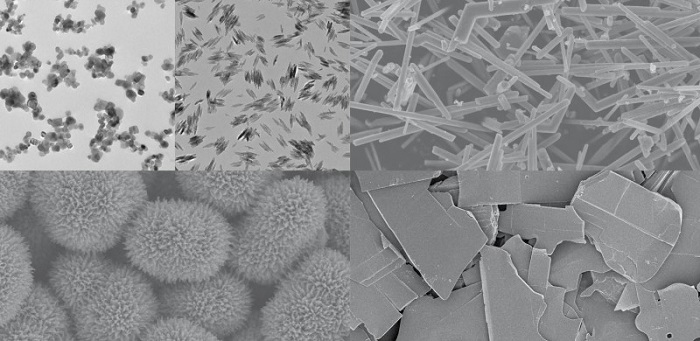

Adding chemicals to inorganic compounds during fabrication can induce crystal growth in specific directions, enabling the production of various shapes, including rods and flakes.

Getting in shape

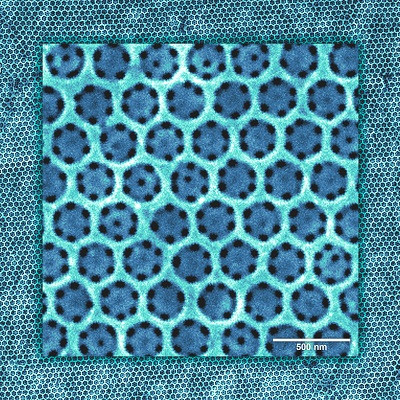

ISK is exploiting the nanotechnology revolution in the coatings industry to tailor titanium dioxide pigments on an atomic level. “One method we use is to add certain chemicals to the titanium dioxide during fabrication,” says Ishibai. “These chemicals can induce crystal growth in specific directions, allowing us to produce shapes such as rods and flakes with nanoscale control.”

To demonstrate how nanoscale shapes can impact pigment properties, Nakao describes ISK’s electroconductive pigments. Rod-shaped particles with special metal oxide treatment have a much higher electrical conductivities than spherical particles. “Customers in the vehicle sector are using our electroconductive pigments in their undercoatings so that they can apply an electrostatic overcoating process,” says Nakao. “Some clients, though, will only use pigments with certain shapes — we’re happy to provide that type of control.”

Other applications include silky pearlescent paints that ‘flip-flop’ in brightness depending on the viewing angle. In this system, flaky particles are arranged in layers in the coating film, creating a hue that does not have the graininess of conventional metallic paints.

Since the structure of titanium dioxide pigments affects how they reflect and absorb light, ISK has found that their shape and surface control technology is especially attractive for the field of colouring materials.

Paint it black

ISK has uncovered another way to manipulate colour with a proprietary wet-chemical technique that grows the inorganic compound into spiky shapes reminiscent of sea urchins. By optimizing the size and dispersion of the prickly pigments, researchers produced pigments that were extraordinarily black and matte.

Matte black coatings that don’t reflect any light could find application in vehicles.

“These types of blacks are unique, because we believe that the pigment structure confines visible light,” says Ishibai. “It’s a pure black with no reflective properties.” Such ultraflat black coatings could find use in optical instruments such as telescopes, as well as in vehicles and electric appliances.

Similar types of profoundly black colours have been seen in bird species with tiny, barb-shaped microstructures in their feathers, the researchers note.

Focus on the future

One of the best aspects of developing new products is the immediate impact they can have, Ishibai notes. “Titanium dioxide is an industrial product, but it’s also closely related to daily life — you can find it within arm’s reach most of the time,” he says. “I feel that these new products are really contributing to society.”

The key to future market opportunities lies in non-traditional applications of titanium dioxide particles to areas such as smart displays, water purification and telecommunications, say Nakao and Ishibai. To realize this, industrial designers and optical component manufacturers will need to look beyond typical ideas about paint pigments.

In all cases, the properties of pigments can be adjusted by selecting specific crystal structures using the dual-process production facility.

Read the original article on Nature.