Li-metal batteries use metallic lithium instead of graphite as the anode, as it has a 10 times higher theoretical capacity (3,860 mAh/g) than graphite (372 mAh/g).

Despite this advantage, lithium can develop dendrites if it is not uniformly and effectively stored during when cycling process, leading to large volume expansion of the electrode, which in turn may shorten the battery’s cycle life and cause safety issues such as fire and explosion triggered by internal short-circuits.

Here’s where the KERI solution comes in.

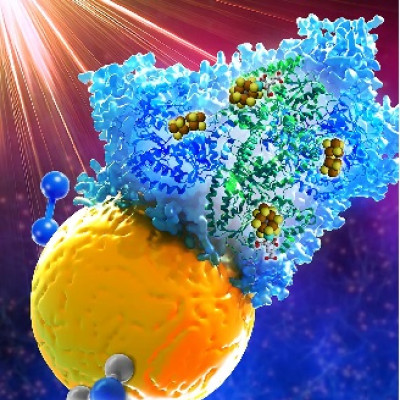

In the new structure, gold controls lithium’s growth direction by reacting with it, thereby inducing Li deposition inside the core. In addition, many nano-sized pores are formed in the shell part to improve the Li-ion movement toward the core space.

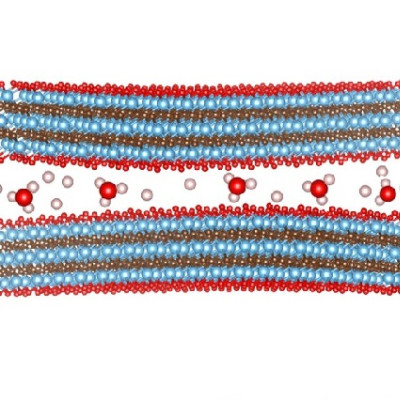

A major challenge observed in the existing hollow core-shell Li host, however, was the Li deposition on the conductive carbon shell, not inside the core, under high-rate charging conditions. Seeing this, the KERI team introduced many nano-sized pores to the shell and achieved significantly improved coulombic efficiency without Li dendrite growth even under a high-current testing condition of 5 mA/cm2.

Simulation results showed that the reduced Li-ion diffusion length by the shell pores and improved Li affinity by the gold nanoparticles kept lithium deposition inside the structure even under high-current charging conditions.

In a paper published in the journal ACS Nano, the researchers also point out that the designed Li host showed excellent cycling performance of over 500 cycles under a high current density of 4C rate (82.5% capacity retention).

“Despite the merit of high capacity, the Li-metal batteries have many hurdles to be overcome for commercialization mainly due to stability and safety issues,” lead scientist Byung Gon Kim said in a media statement.

“Our study is invaluable in that we developed a technique for mass production of Li-metal reservoir with high coulombic efficiency for fast-rechargeable Li-metal batteries.”

Read the original article on Mining.