When computers shrink to micro size, machines take up less space than a pinhead, and devices perform chemical analyses on dewdrop-sized fluid, the equipment components must downsize correspondingly.

At DTU Science Park in Lyngby, ATLANT 3D Nanosystems thinks big when developing mini-scale equipment. The start-up is setting a completely new standard for 3D printing. Here it develops 3D printers that can produce microscopic prints in atom-thin layers. This offers many advantages, says Maksym Plakhotnyuk, who is the CEO and one of the three founders of the start-up:

“Conventional micromanufacturing of, for example, a contact electrode consists of a series of complex processes, each of which requires separate machines and specially trained technicians to operate them. What we’ve developed is what you might call direct printing. We upload a CAD file—a digital drawing of the desired product—to our printer, which then prints exactly the 3D product you want in exactly the material you want. And there’s just one technician to operate the printer.”

With ATLANT 3D Nanosystems’ equipment, it will typically take just a few minutes to create such a microelectrode, while—with conventional equipment—it will take several hours. So the technology is both faster and more flexible than conventional microfabrication.

Atom-thin layers

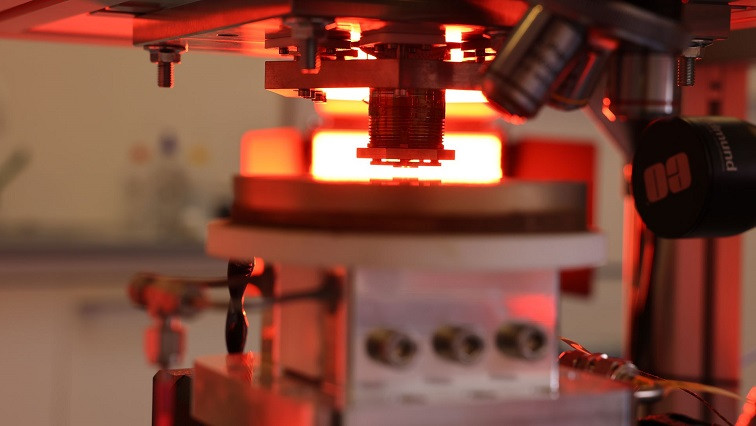

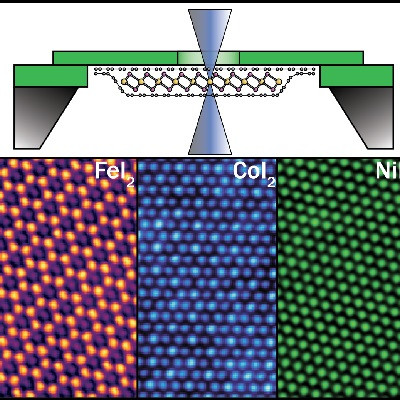

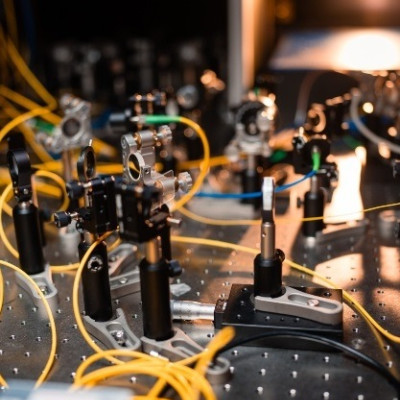

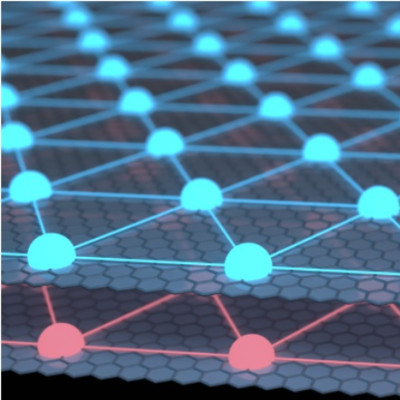

Another unique aspect of the technology is that it combines a micro nozzle and the use of ALD (Atomic Layer Deposition) technology. This technique makes it possible to deposit a chemical substance in a layer with a thickness of only a single atom or molecule by blowing gases with different chemicals down onto a print surface. On the surface, a chemical reaction then occurs with deposition of the desired substance in atom-thin layers down to 0.1 nanometre.

Finally, ATLANT 3D Nanosystems has developed a process in which it moves the print surface so that the gas jet hits the surface in a predetermined pattern. If this pattern is changed from layer to layer, a micro-sized 3D item can be built.

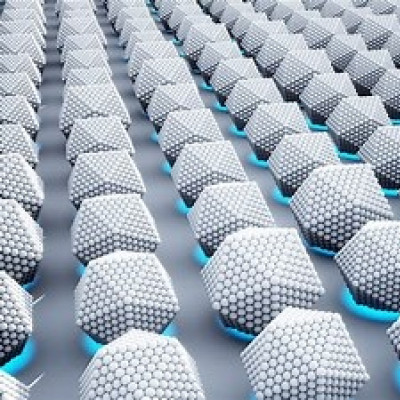

The start-up’s technology also makes it possible to print several layers of different material on top of each other in a continuous process. This makes it possible to create highly complex prints. Conventional microfabrication methods require several separate processes and machines to perform the work.

When ATLANT 3D Nanosystems produces prints, it can currently print items as small as 400 micrometres in width. However, the goal is to arrive down to about one micrometre. The items on which you can print can be as large as 30 by 30 centimetres, which become densely covered with uniform 3D microprints. Over time, the goal is to reach items over a metre with tight-fitting microprints, if needed.

High-flying development

ATLANT 3D Nanosystems was established in 2018, but the company has already gained great international attention. The start-up’s first customer was no less than NASA, which, in 2021, received an ultra-compact 3D printer, which is designed to print in space, where gravity is close to zero.

In 2021, the start-up was awarded a major international prize as the winner of Hello Tomorrow Global Challenge among more than 4,000 technology start-ups. In addition, ATLANT 3D Nanosystems has received a Gold Go Global Award from the International Trade Council.

In autumn 2022 the company succesfully raised 15M USD from UK venture capital firm West Hill Capital and also from existing investors including a leading Japanese corporation. The investment will enable ATLANT 3D Nanosystems to develop advanced manufacturing hubs that both can ensure radical innovation in manufacturing while eradicating supply chain issues.

Maksym Plakhotnyuk arrived in Denmark from Ukraine in 2014 to start in a PH.D.-position at Technical University of Denmark (DTU). Here he worked with microfabrication and nanofabrication techniques as part of his PH.D. The breakthrough for ATLANT 3D Nanosystems' technology came when, in 2018, he initiated a collaboration with Ivan Kundrata and Julien Bachmann, who specialize in machine development and ALD processes, respectively.

ATLANT 3D Nanosystems has currently successfully printed with eight different materials, and four of them have a clear application potential. These are platinum, titanium oxide, aluminium oxide, and zinc oxide. The material that currently has the greatest potential is platinum, which is particularly useful in sensors and other microelectronics.

Titanium oxide can be used for catalysts and optical items. Aluminium oxide is used as a protective film against radiation, while zinc oxide is used in the manufacture of batteries, solar cells, and touch screens.

Numerous applications

In the electronics industry, there are infinite applications. Everything from mobile phones to hearing aids and car airbags contain microscopic electronic devices that can advantageously be produced using 3D printing technology.

Microscopic electronics work with low electrical voltages and are therefore very sensitive to electromagnetic effects. Here, the new technique can be used to produce a thin film that provides a shield against the electronic radiation and thus ensures the functionality of the electronics.

In the future, mobile phone screens can pick up 5G signals when a transparent antenna is printed on the screen using ATLANT 3D Nanosystems’ technique. Micromachines between 20 micrometres and 1 millimetre are rapidly emerging, and here ATLANT 3D Nanosystems will also be able to supply the ultra-small components.

Finally, Maksym Plakhotnyuk mentions so-called smart glasses, that is glasses in which a thin printed electronic film makes it possible to use the glasses as a computer screen, while it is concurrently possible to see through the lenses. This is something that is already known from fighter pilots’ visors.

ATLANT 3D Nanosystems is planning to establish offices in both the United States and Asia, where the demand for micro-scale printing is increasing.

Maksym Plakhotnyuk expects that ATLANT 3D Nanosystems will begin to produce printers for its customers’ development departments and to produce commercial print products during 2023.

Read the original article on Technical University of Denmark.