Czech Republic-based nanofibre specialist Nano Medical has developed two initial medical products it is launching under its ChitoFib brand based on chitosan fibres, to protect wounds from contamination and promote and accelerate healing.

At the forthcoming Filtech exhibition taking place in Cologne, Germany, from February 14-16, the company will introduce the ChitoFib Patch NW, a nonwoven with individual chitosan nanofibre layers, and ChitoFib Patch – finished medical plasters and wound covers based on the nonwoven composite.

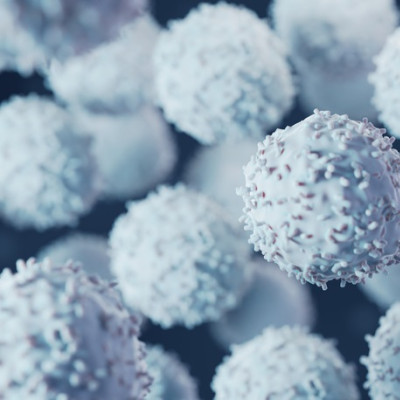

The nanostructure combined with biopolymers supports cell proliferation and creates a natural structure for areal wound healing.

The principle of damp healing is to create gel in contact with liquids – the creation of a humid environment – which enables new epidermal cells to migrate more easily to the wound surface. A benefit for the patient is the faster healing of the wound, a longer interval between replacing bandages, the prevention of scabs and the restriction of pain.

The extremely fine nanofibre structure of ChitoFib Patch NW works as a protective filter against potential microbial contamination of the wound from the exterior environment. The natural antimicrobial effect of chitosan also helps prevent possible microbial infection from the environment and it degrades naturally due to the impact of body fluids.

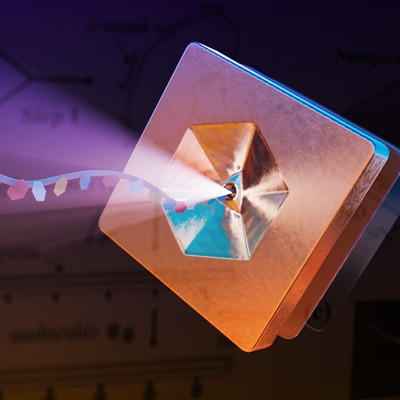

Nano Medical employs Nanospider surface filtration which enables the manufacture of very homogenous nanofibre membranes like the ChitoFib product. The compactness and porosity of the nanofibre membranes are also suitable surface filtration application. The use of the membrane considerably increases filtration efficiency and prolongs the service life of a filter.

The company has also patented a technology for deeper filtration called MACspiner which makes it possible to use nanofibres in areas where they could not have previously been used due to high production costs. This technology produces nanofibres in an open ‘fluffy’ structure which supports the principle of deep filtration and provides the materials with the ability to hold dust with a high filtration efficiency and excellent breathability.

Read the original article on Innovation in Textiles.