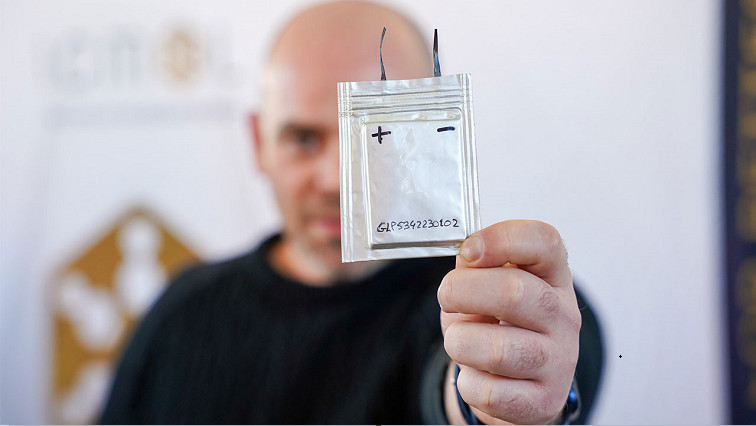

Graphenano and the Institute of Molecular Science (ICMol) of the University of Valencia have developed the first battery cell without current collectors or metal terminals. The system, using graphene and carbon nanomaterials instead, enables the manufacture of safer, lighter, and more efficient batteries. Its application in electric cars, aviation, and stationary storage, inter alia, revolutionizes the battery industry.

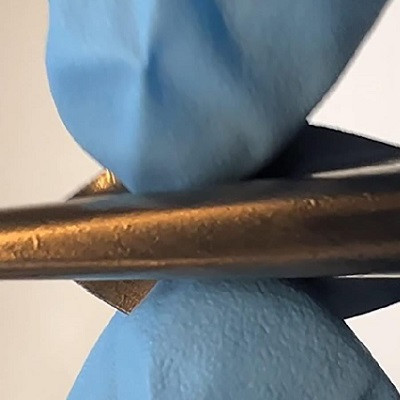

The project has succeeded in removing the copper, aluminium or steel sheets, the materials generally used in conventional batteries to evacuate the electric current generated. Simultaneously, the metallic tabs (current terminals), usually made of nickel or other metals, which are responsible for transferring the energy from the inside to the outside of the battery, have been eliminated.

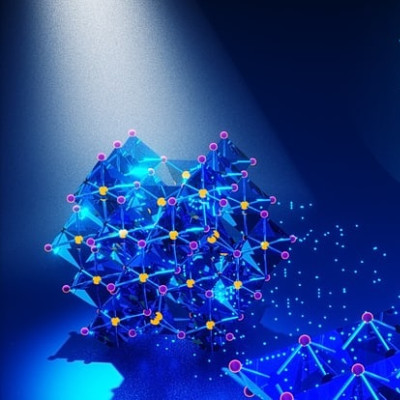

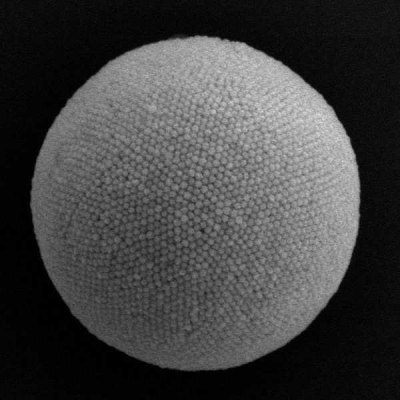

The replacement of these metals by graphene and other carbon nanomaterials - materials with good electrical conductivity - significantly reduces the weight and volume of the devices. Furthermore, as ascertained in tests, it increases the energy density by 30-60% and eliminates the risk of explosion or fire accidents on contact with air.

“We have patented a technology that solves the problem of battery safety with a disruptive approach," explains Martín Martínez, CEO of Graphenano. “Our system provides such chemical stability that the battery does not burn on contact with air, even in the presence of lithium. Therefore, the heavy safety shielding of existing batteries can be dispensed with," remarks the entrepreneur.

This technique therefore permits the development of safer, lighter, more powerful, more compact and, definitely, more sustainable batteries. The reduction in weight and volume increases both energy density (in watt hours per kilo) and volumetric density (watt hours per litre). In addition, it is not necessary to replace the current cell assembly machinery, which facilitates its implementation without excessive industrial costs.

Sustainable and recyclable

The new cell is more environmentally sustainable as it does not contain collector metals. Moreover, it significantly reduces its carbon footprint and promotes the recycling of materials in line with Battery Passport, the European Commission's strategy to control the full life cycle of the battery. “By eliminating these metals, which are scarce on Earth, will undoubtedly have an impact on the economy and global geostrategy," claims Gonzalo Abellán, leader of the 2DChem group (ICMol) involved in the project along with Professor Eugenio Coronado's team at the University of Valencia.

“This new system is very versatile and can be used in several chemistries, such as those using lithium or sodium. Furthermore, it expands a new field in silicon batteries, supercapacitors, fuel cells and hydrogen electrolyzers”, points out Abellán. “Partnership between innovative companies, such as Graphenano, and research centres of excellence such as ICMol, is essential for economic and social progress, and this is an illustration of that", concludes the scientist.

The Graphenano Group's energy division manages, develop, and operates the business of graphene polymer cells for use in several applications. The Institute of Molecular Science of the University of Valencia focuses its work on the molecular aspects of nanoscience and the study of materials with magnetic, electrical, or optical properties. Since 2015, it has been a ministerially recognised centre as a María de Maeztu Unit of Excellence.

Read the original article on EIN Presswire.