That includes a nano-thin window coating that can more than double the thermal protection for residential and commercial windows. That technology is now on its way to commercialization, thanks in part to $5 million in new federal funding from Sustainable Development Technology Canada.

“Windows are the weakest energy link in any building,” says Kherani, a professor in the department of material science and engineering in the Faculty of Applied Science and Engineering who is jointly appointed to the Edward S. Rogers Sr. department of electrical and computer engineering.

“Think of heat escaping in the winter months and heat entering the cool, ventilated space during the summer months," says Kherani, who co-founded 3E Nano in 2015.

Kherani explains that a window’s resistance to heat flow is measured by the R-value, which increases based on its ability to prevent heat from flowing into or escaping from a building. Currently, 3E Nano windows – in prototype as well as in pre-alpha deployment – rate R8 and higher.

"This compares remarkably to an average window whose R-value lies in a range from R1 of a single pane, to R3, a dual pane.”

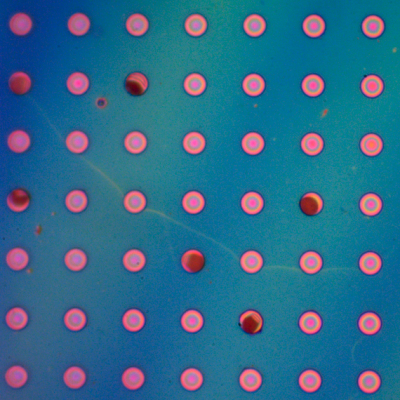

How was 3E Nano able to achieve this breakthrough? In its simplest configuration, the 3E Nano coating comprises a nano-thin metallic film sandwiched between two sapphire-like nano-thin films. This three-layered stack is opaque to certain wavelengths of light, but not others. As a result, the coating can control the flow of light entering and leaving the building over three parts of the solar spectrum: the visible, the near-frequency infrared and the mid-frequency infrared.

Both near-infrared light – which accounts for almost half of the sun’s total energy – and mid-infrared light can be reflected away. This keeps the sun’s heat from penetrating indoors, but it also keeps room heat inside the building from escaping through the windows, achieving low emissivity. At the same time, natural visible light is allowed through the window to the interior, reducing the need for artificial interior lighting.

Kherani believes 3E Nano’s coating is poised to become a mainstream product. He credits the industry experience of 3E Nano’s team with a critical pivot in the research.

“Combining earth-abundant aluminum and nitrogen results in a coating material similar to sapphire in its optical and structural properties,” he says. “The stability and multi-functional character of the sapphire-like structure is suited to low-cost, high-volume manufacturing.”

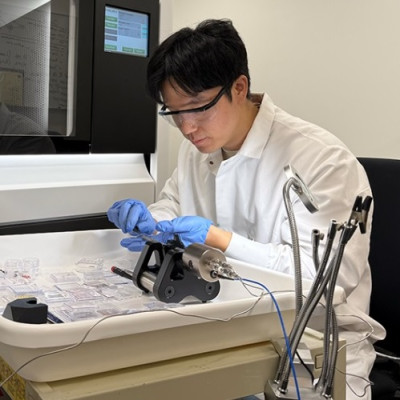

The coating is applied by sputter deposition – a process which hurls argon atoms into an aluminum target in a vacuum system, knocking the aluminum atoms like billiard balls into a lightweight polymer substrate.

After adding nitrogen gas, the resulting chemical reaction forms a colourless film only tens of nanometres thick (approximately one-thousandth of the thickness of a hair strand). This combined with a nano-thin silver layer results in a robust coating that can be tuned for optical and electrical properties.

Kherani and his team envision other aspects of the perfect window as integrated functionalities ranging from metamaterial structuring to dynamic systems that maintain ideal temperatures and daylighting (the practice of placing windows so that sunlight can provide effective internal lighting) within buildings.

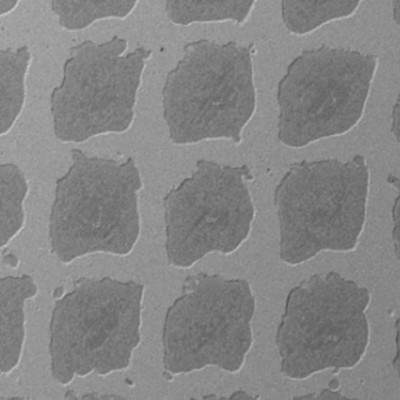

“In the lab, we’ve created a metamaterial that retains low emissive and solar-control properties but has high transparency in the gigahertz range critical for communication – nature-inspired with near-invisible hexagonal honeycomb patterns,” Kherani says.

“Professor Kherani has his eye on sustainability solutions that remain scalable,” says Professor Deepa Kundur, chair of the department of electrical and computer engineering. “His startup 3E Nano is a shining example of how industry can shape and direct research, and he’s given 3E Nano every chance at a positive impact in the green marketplace.”

Kundur also points out that it's because of researchers like Kherani that U of T was recently named a top-10 research institution for global innovation.

Kherani is encouraged by 3ENano's progress and optimistic about the company’s ability to help transform the building sector, which ranks a close second to transportation in energy-related carbon dioxide emissions.

“Although the shortest distance from point A to point B is a straight line, finding that straight line is not a simple matter," he notes. "On the other hand, we are in a promising place today, and we can clearly see where we need to be.”

Read the original article on University of Toronto.