For the Syzygy modular reactors, Emerson will provide hardware, software and services, including its DeltaV distributed control system; industrial software for process simulation and data analytics; Rosemount instrumentation to measure pressure, temperature, level and flow; and Fisher valves to control pressure and improve safety.

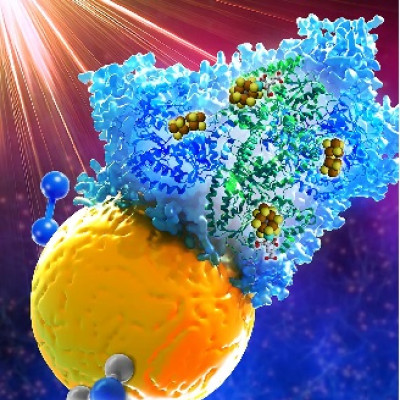

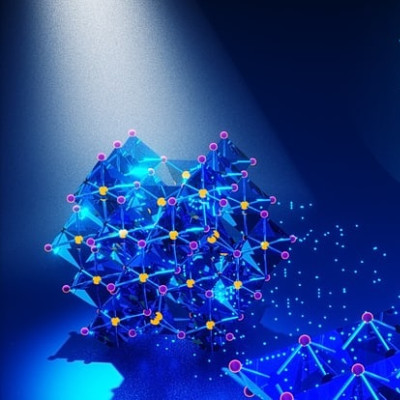

The breakthrough for this technology came when Rice University researchers embedded a nanoparticle of a traditional catalyst material into the surface of a larger, light-harvesting plasmonic nanoparticle. This two-part nanoparticle structure, known an antenna-reactor complex, provides more efficient capture and transfer of light energy to the reactive sites on the catalyst, effectively replacing the need for thermal energy from the combustion of fossil fuels with light. Also, researchers realized they could replace traditional rare, expensive catalytic metals, like ruthenium, with abundant, affordable light-reactive metals like iron.

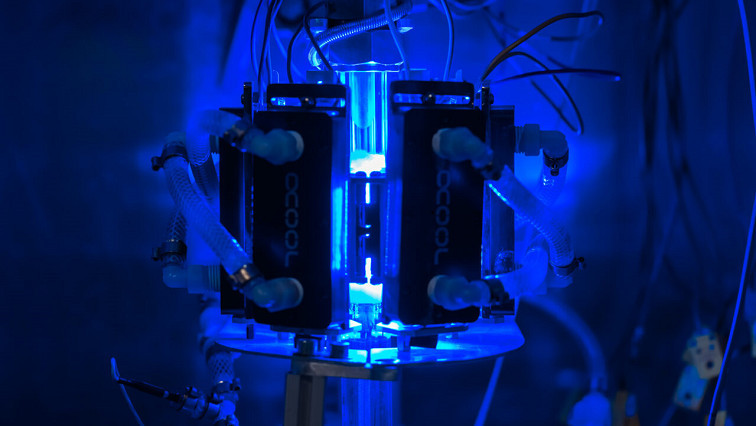

Rigel photoreactors (photo) feature a photocatalyst-filled sleeve surrounded by a light box. Each reactor is fully contained in an outer shell. Banks of these reactors can be stacked to offer flexible installation sizes ranging from 1 to 100 ton/d of product, such as H2, methanol and fuels.

Syzygy has three field trials planned for 2023, located in North Carolina, California and South Korea. Last August, for example, the company announced a joint development agreement with Lotte Chemical, Lotte Fine Chemical and Sumitomo Corp. of Americas to test a fully electric chemical reactor for clean hydrogen production. The reactor will be installed and brought online in the second half of 2023 at Lotte facilities in Ulsan, South Korea.

Read the original article on Chemical Engineering.