Silicon solar cells are approaching their theoretical efficiency limit of 29.4 percent. But last year scientists revealed they created tandem solar cells that for the first time exceeded the 30 percent efficiency threshold. Now they not only reveal how they did it, but another team also say they have broken this record using a different approach.

The most common solar cells use silicon to absorb light. Modern commercial silicon solar cells now reach efficiencies of more than 24 percent, and the best lab cell has an efficiency of 26.8 percent.

One way to boost a solar cell’s efficiency is by stacking two different light-absorbing materials together into one device. This tandem approach increases the spectrum of sunlight the solar cell can harvest.

More and more, scientists are investigating the use of perovskites in tandem solar cells, since these crystals are inexpensive and easily produced in labs. A common approach is to use a top cell made of perovskites to absorb higher-energy visible light and a bottom cell made of silicon for lower-energy infrared rays.

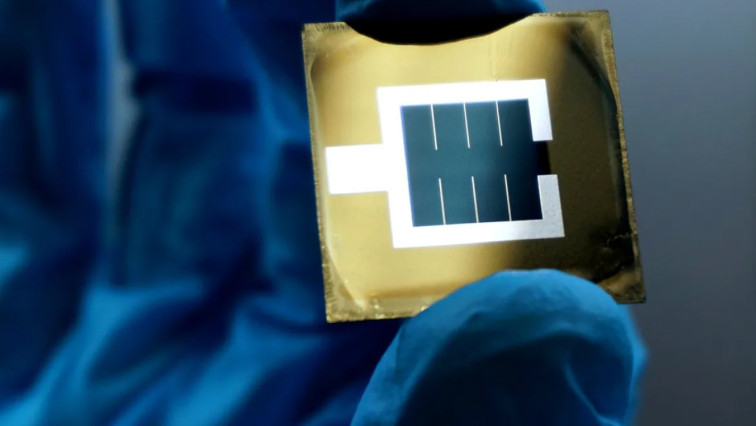

In 2022, a team of German researchers revealed how they developed a perovskite-silicon tandem solar cell with an efficiency of 29.8 percent, while a separate group at the Swiss Center for Electronics and Microtechnology in Neuchâtel, Switzerland, and their collaborators set a new record of 31.25 percent.

“It is the first time a technology with an architecture compatible with mass production has reached an efficiency above 30 percent,” says Quentin Jeangros, a materials scientist at the Swiss Center for Electronics and Microtechnology.

Now the Neuchâtel researchers and their colleagues divulged how they built their device, while the Berlin scientists and their collaborators unveiled a new tandem solar cell with an efficiency of up to 32.5 percent.

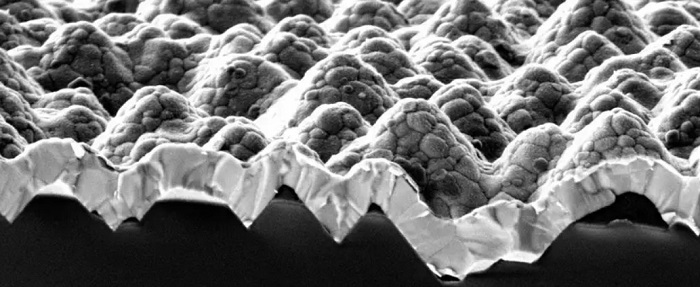

The Neuchâtel group revealed their device consisted of a perovskite top cell on a silicon bottom cell featuring pyramids a few micrometers in height. Using a textured surface instead of a flat one enhanced the surface’s light trapping capabilities.

This electron-microscopy image of the front side of the high-efficiency perovskite-on-silicon tandem solar cells reveals a textured surface and carbon-60 fullerene layer—both of which helped maximize light capture and prevent charge loss.

This group used a two-step method for depositing the perovskite. First they used thermal evaporation to lay down an inorganic template on the pyramid-covered silicon bottom cell. Next they used a solution to crystallize this scaffold into perovskite. This helped ensure the perovskite also formed pyramids to catch light.

A key problem that perovskite-silicon tandem solar cells have faced is preventing charge loss from negatively charged electrons and positively charged holes recombining in the perovskite top cell after light helps separate these charges. One strategy the Neuchâtel and Berlin teams both employed to overcome this problem was to place a carbon-60 fullerene layer that can efficiently extract electrons from the perovskite.

However, at defects on the perovskite surface, electrons and holes could recombine. The Neuchâtel group avoided this by using phosphonic acid additives during crystallization of the perovskite cells that helped prevent these defects from forming.

“These results show that the technology is ready to move forward to the next stage of its development, meaning that stability and scalability aspects should now be of central focus,” says Xin Yu Chin, a materials scientist at the Swiss Federal Institute of Technology Lausanne’s photovoltaics lab in Neuchâtel.

Using a different approach, the Berlin team relied on an ionic liquid known as piperazinium iodide. The fluid is a salt made of both positively charged cations and negatively charged anions. This let it modify positive and negative surface defects on the perovskite to reduce recombination.

Both these records were surpassed by scientists at the King Abdullah University of Science and Technology (KAUST) in Saudi Arabia, who developed perovskite-silicon tandem cells with 33.2 percent efficiency in April and 33.7 percent in May. Ultimately, “we believe 35 percent is an achievable target,” Jeangros says.

The Neuchâtel group is now focusing on developing industrially applicable processing methods for scaling up production and on improving the operational stability of these devices. “It is likely that the technology still needs 5 to 10 years to make it to the market,” Chin says.

Read the original article on IEEE Spectrum.