Updating investors on the commercialisation progress and sales development of THERMAL-XR, the company said the blending plant is expected to have the capacity to produce up to 500,000 litres of THERMAL-XR RESTORE coating a year, subject to graphene production, when operating two blends per eight-hour shift, 250 days per year.

This capacity enables future service growth well into the future, it added.

The company said it has also installed laboratory facilities for quality and control requirements and progressing research and development, to extend and enhance the THERMAL-XR portfolio into additional industries and applications.

"We are very excited to commission our own blend plant and to have manufactured 1,000 litres of THERMAL-XR RESTORE as part of our distributor's initial orders, which are subject to in-country regulatory approvals,” GMG managing director and CEO Craig Nicol said in a statement.

“This is an important step to becoming a globally recognised manufacturer and marketer of energy-saving products."

GMG said it has intensified sales activities since it received approval from the Australian government to produce and sell TXR at scale in February 2023. This has resulted in distribution agreements in North America, Singapore, Thailand, Indonesia, and South Korea to the heating, ventilation and air-conditioning refrigeration (HVAC-R) market.

Additionally, it said wider potential industries are being assessed including energy savings applications in data centres and for energy producers such as liquified natural gas plants, where THERMAL-XR has the potential to increase production capacity and energy efficiency.

The company said it is reviewing important initial and forward sales orders that it has received from HVAC-R distributors against their market introduction timelines and their local country approvals.

It also plans to submit an application to the USA’s Environmental Protection Agency (EPA) for approval of THERMAL-XR with all the supporting scientific testing, with a statutory 30-day review period. Given the number of approved graphene material products, GMG said it is confident of an approval.

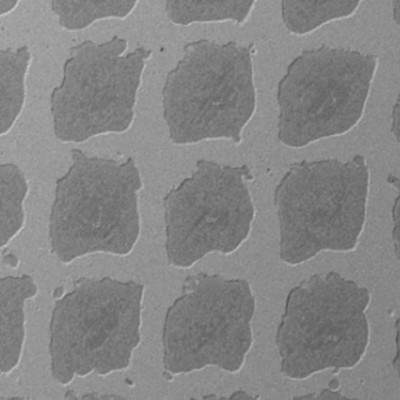

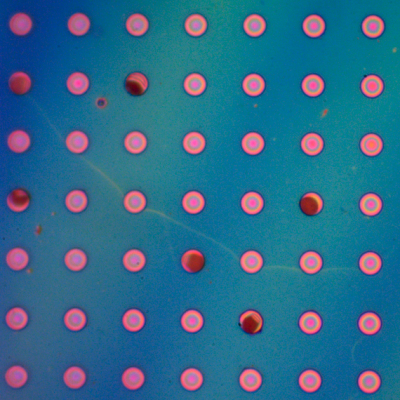

THERMAL-XR COATING SYSTEM is a unique method of improving the conductivity of corroded heat exchange surfaces and improving and maintaining the performance of new units at peak levels.

The process coats and protects heat exchange surfaces while improving and rebuilding the lost corroded thermal conductivity and increasing the heat transfer rate by leveraging the physics of GMG Graphene, resulting in an efficiency improvement and a potential power reduction.

Read the original article on Proactive Investors.