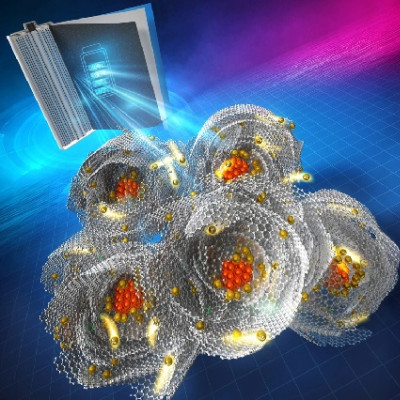

Ludwigshafen, Germany and Chico, California – BASF, a globally leading battery materials producer, and Nanotech Energy, a worldwide leader in the field of graphene-based energy storage products, have agreed to partner to significantly reduce the CO2 footprint of Nanotech’s lithium-ion batteries for the North American market. The agreement aims to close the loop for lithium-ion batteries in North America, with BASF producing cathode active materials from recycled metals in Battle Creek, Michigan, for the usage in lithium-ion battery cells produced by Nanotech Energy. Feeding recycled metals into the production of new lithium-ion batteries can reduce the CO2 impact of batteries by about 25 percent compared to the use of primary metals from mines.

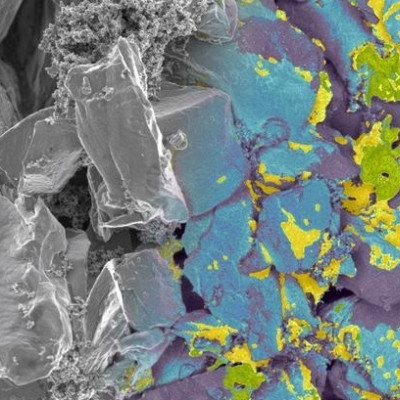

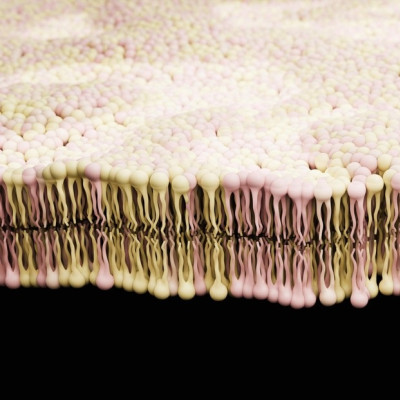

Both companies will additionally partner with American Battery Technology Company (ABTC), a lithium-ion battery recycling company in Reno, Nevada, and TODA Advanced Materials Inc. (TODA) with decades of experience in manufacturing specialized pCAM (precursor for Cathode Active Material) and metal hydroxide material located in Ontario, Canada, to establish such a localized battery value chain for the North American consumer electronics and automotive industries. Along that chain, battery scrap and off-spec material from Nanotech’s pilot operation in Chico, California, as well as from its planned commercial facility will be recycled by ABTC. The battery-grade metals as recovered by ABTC – such as nickel, cobalt, manganese, and lithium – will be subsequently used by TODA and BASF to produce new precursors and cathode active materials, respectively. Nanotech will then use these materials again in its battery cell production – overall, a truly circular economy in North America.

BASF recently announced battery recycling capacity in Europe and is already providing recycling services and cathode active material based on recycled metals as a closed-loop solution in Asia for years.

Daniel Schönfelder, Senior Vice President Battery Base Metals and Recycling at BASF, summarized: "Our partnership with Nanotech, ABTC, and TODA marks an important step for BASF’s global battery recycling business. Now, we are establishing the first closed-loop system in North America. This enables BASF and Nanotech to produce lithium-ion batteries with locally recycled content."

Curtis Collar, Chief Marketing and Sales Officer at Nanotech Energy, said: "By working together, our four companies can pool their expertise and drive better and more sustainable outcomes for the entire North American electric vehicle and consumer electronics industries. This is a major milestone among the ongoing advances and growth of the lithium-ion battery market, and we are proud playing such a key role in the reduction of CO2 emissions along the battery value chain."

Read the original article on BASF.