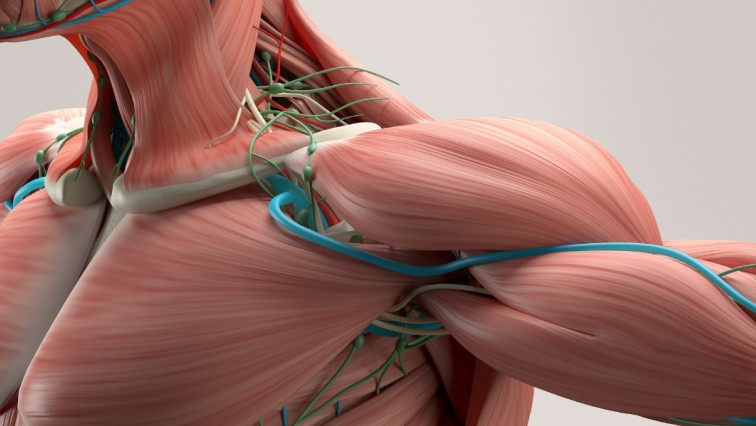

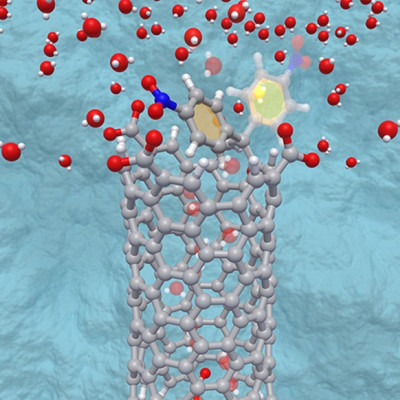

The team wet-spin a mixture of GO nanosheets and poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT: PSS) into a composite fiber in which the flexible, conductive polymer is embedded in between aligned, closely-packed nanosheets. The addition of a depleting agent, polyethylene glycol (PEG), improves toughness and elasticity, while chemical reduction of GO to rGO increases electrical conductivity. Finally, the composite fibers are plied with nylon yarns to create a hierarchical composite actuator with capabilities better than typical biological muscles (75 J/kg work capacity and 924 W/kg power density).

“Most soft actuators are based on responsiveness to heat, light, pH, and water, [so] actuation efficiency is low and actuation speed is slow”, said Shu Yang, who led the work. “We addressed the paradox in actuation performance and the distinct limitations of soft actuators.”

While electrically stimulated actuators, such as those based on carbon nanotube (CNT) aerogel sheets or bundles of closely aligned fibers, respond quickly and forcefully, they tend to be brittle and require specialist equipment for fabrication. Instead, the team exploited the assembly of GO sheets into a lyotropic liquid crystal (LLC) phase.

“We pre-assemble GOs into an ordered phase before they are assembled into fibers, which is critical to their formation of zigzag brick-and-mortar close-packing morphology in the fiber format,” explains Yang, “[which] leads to superior actuation performance based on charge injection and electrostatic repulsion.”

“We demonstrate rapid and forceful actuation through electrostatic repulsion between rGO nanosheets in fiber form, achieving high energy efficiency, high power density, and high weight-lifting capability that can meet or beat the performance of biological muscles,” adds Yang.

Actuators fabricated from the composite fiber respond quickly (80 ms) and reversibly over 10,000 cycles. Crucially, the new composite is mainly inorganic but does not suffer from the typical brittleness of such materials because of addition of polymeric additives.

“Our actuators are good for bending, but not good for twisting or making knots,” admits Yang, however. “[But we are now] exploring different geometries and topologies, as well as material compositions, for bending and twisting.”

Read the original article on Graphene-Info.