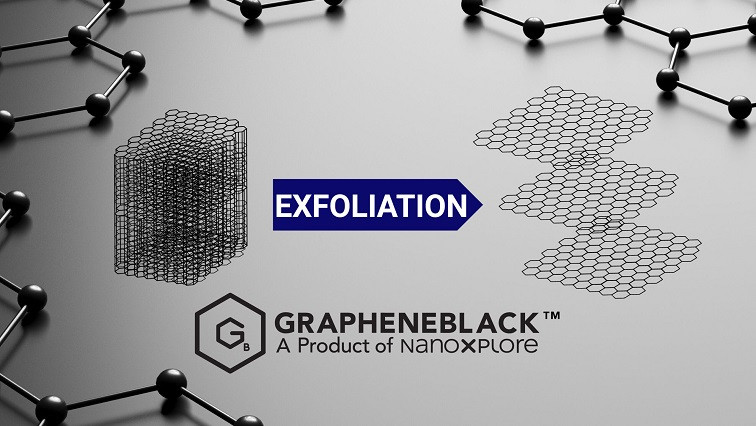

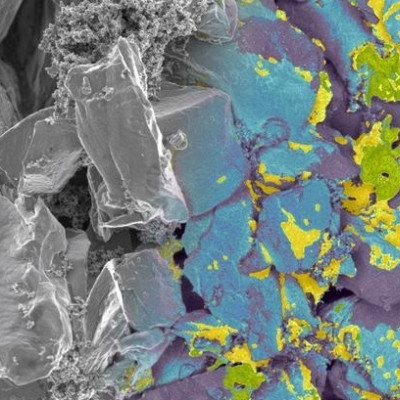

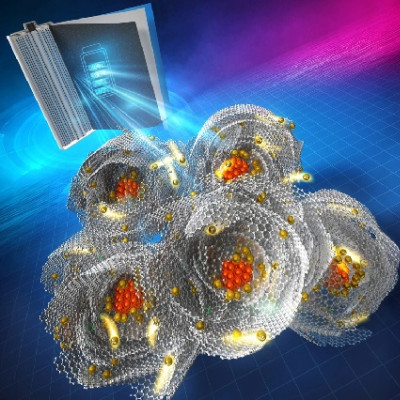

The dry process centers on an advanced exfoliation technology with innovative media that enables high yield exfoliation without the introduction of impurities.

The fusion of NanoXplore’s strong intellectual property portfolio and the strategic patents acquisition of XG Sciences has yielded in this significant advancement in graphene production. The amalgamation of eight different patents registered and/or granted in Australia, Canada, United States, Taiwan, China, and South Korea together with NanoXplore’s knowledge and experience deliver a graphene with a mix of performance and cost-effectiveness. The research and development related to this process started a decade ago with an investment of nearly $40M to date by NanoXplore and XG Sciences.

NanoXplore’s novel dry graphene manufacturing process has several benefits compared to the traditional liquid exfoliation methods. In terms of capital expenditures, dry manufacturing process delivers nearly 50% reduction versus liquid exfoliation process. According to the Corporation’s current estimation, a net 8 000 metric tons capacity requires only $20M in capital expenditures, with a quarter of the current square footage required as opposed to liquid exfoliation process. NanoXplore has secured key suppliers, ensuring a robust supply chain for the main equipment. Equipment procurement is streamlined with off-the-shelf solutions, with an estimated lead time of 8-12 months. The Corporation is planning to start purchasing the equipment during 2024 calendar year.

NanoXplore’s novel dry graphene manufacturing process could bring the Corporation within cost parity with traditional carbon additives such as carbon black. The cost reduction results primarily from using low grade waste graphite (which is derived from graphite anode production process) as feedstock. Furthermore, it is highly scalable and operates on a continuous basis, streamlining production efficiency. Superior processability and long-term performance of dry-processed graphene offers investors a more attractive proposition and will expand the Corporation’s total addressable market and accelerates commercial adoption of graphene.

With granted patents already secured, this proprietary technology boosts some key physical properties in polymers by 20% compared to existing products for applications with over 20-yr longevity requirements. The technology finds potential applications in batteries and lightweight composites, enhancing its appeal in cutting-edge industries. This new manufacturing process also opens doors to a myriad of applications, including plastic pipes, geosynthetics, recycled plastics, concrete, drilling fluids, and insulation foams, among others.

The new dry manufacturing process marks a paradigm shift, substantially reducing the environmental footprint associated with traditional graphite exfoliation methods. This new process addresses environmental concerns associated with water usage, eliminating washing and drying steps that contribute to increased costs and environmental impact.

NanoXplore's CEO, Soroush Nazarpour, expressed enthusiasm about this breakthrough, stating, "Our team's dedication to innovation and sustainability has led to this remarkable achievement. The dry manufacturing process not only underscores our commitment to environmental stewardship but also reinforces NanoXplore’s position as the leader in cost-effective, high-performance graphene solutions. This technological advancement reinforces NanoXplore's commitment to pushing the boundaries of what is possible in field of carbon technology and reaffirms its role as an industry pioneer.”

Read the original article on GlobeNewswire.