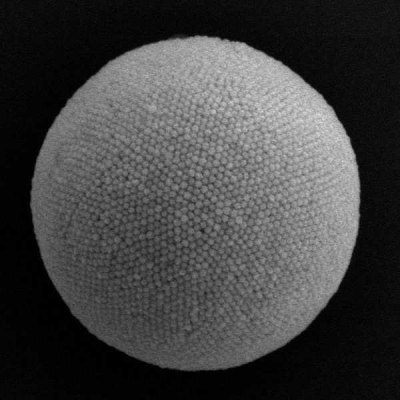

The performance of the production unit, according to GMG's CEO and managing director, Craig Nicol, has "exceeded the Company's expectations in both graphene production rate and graphene quality. The company continues to perform minor optimizations with this new production plant which have both increased production yield and quality of the graphene".

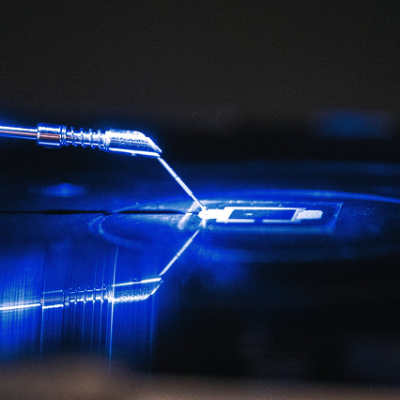

The company has also authorized a total of AUD$250,000 (around USD$168,000) of capital expenditure for new equipment for quality assurance and quality control purposes of the Company's graphene for its graphene aluminum ion battery and its liquid graphene products, Thermal-XR and G lubricant. The equipment being procured by the company includes: a Raman spectrometer and a particle size analyzer, amongst others. To date the Company has been working with various universities to obtain this analysis. Once the equipment is procured, delivered, commissioned and operational, it will largely be self-sufficient on testing of its nano materials.

Craig Nicol commented: "We are very excited to see the new modular plant exceed expectations in terms of graphene production and quality. The expansion of our graphene characterization equipment will also reduce learning loop times for optimization projects where we no longer have to wait for university equipment access. The graphene production system uses GMG's self developed innovative plasma technology which creates the high-quality graphene GMG's end products need to deliver their notable benefits."

Graphene Manufacturing's chairman and director, Jack Perkowski, commented: "It is great to see the Company's production technology maturing to this point as this is GMG's fundamental core competency. Ongoing graphene production and characterization developments will only support the company's ability to develop and provide its useful liquid graphene products and graphene aluminum ion battery."

Read the original article on Graphene-Info.