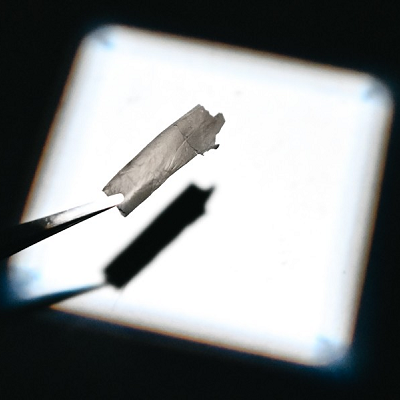

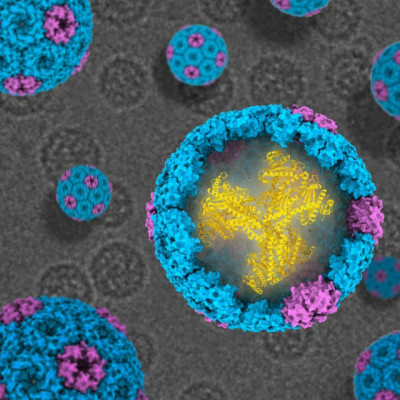

The technology, featuring graphene oxide-based hollow fibre ultrafiltration and nanofiltration membranes, was developed over more than a decade of research and development. The ultrafiltration technology utilizes a graphene oxide-block copolymer composite renowned for its exceptional chemical and thermal stability, making it ideal for harsh industrial applications. Its unique surface chemistry forms a protective water layer that effectively prevents fouling. The nanofiltration technology employs a robust single-layer modified graphene oxide membrane with synthetic water channels, enhancing selectivity and permeability. This enables efficient molecular-level separation and differentiation between monovalent and multivalent ions.

These advancements promise superior performance and broaden potential applications across industries, including textiles, agriculture, food and beverage, pharmaceuticals, pulp and paper, chemicals, microelectronics, semiconductors, and mining.

Memsift Innovations’ membrane-based solutions leverage cutting-edge technology to address some of the most challenging industrial liquid waste treatment problems. Its TS-30 system employs a unique thermodynamic principle for thermal separation, while the advanced GOSEP Ultra and nanofiltration membranes are highly effective at separating various pollutants and monovalent ions from multivalent ions, even under harsh operating conditions. The company is now enhancing its product portfolio by acquiring next-generation graphene oxide membrane technology from Ngee Ann Polytechnic.

"This is a highly anticipated milestone in our journey,” said Dr J Antony Prince, founder & CEO of Memsift Innovations. “The new graphene membrane technology offers several advantages over current state-of-the-art nanofiltration technologies. This chemical-resistant hollow fiber nanofiltration technology will integrate seamlessly as a separation and purification unit before our membrane distillation concentration technology, aiding in chemical recovery and closing the industrial liquid-waste loop. This advancement solidifies our market position in industrial liquid waste treatment and resource recovery, enabling us to provide our customers worldwide with the most advanced and valuable technologies."

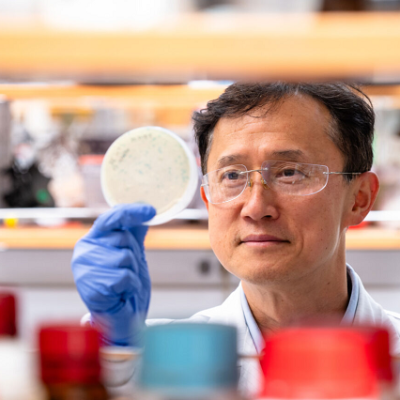

Dr Jason Tang, director of the Centre for Environmental Sustainability and chief sustainability officer at Ngee Ann Polytechnic, added: “The graphene oxide membrane technology we developed is groundbreaking, as it can reduce energy consumption by up to 50% and has a lifespan twice as long as conventional membranes. My team is excited about the potential of this technology to enhance the sustainability of industrial water treatment”.

Read the original article on Filtration+Separation magazine.