In a study published in the journal Advanced Materials Interfaces, researchers at Griffith’s Queensland Micro- and Nanotechnology Centre explored how specific surface structures – called re-entrant microstructures – could repel water and other liquids.

The paper – chosen as the Editor’s Choice and set to feature on the journal’s cover – revealed how factors such as shape, material, and spacing of these microstructures influenced their ability to resist wetting or liquid spreading.

“Our research dives deep into why some surfaces are better at repelling water than others,” said Dr Navid Kashaninejad, one of the study’s lead researchers.

“This understanding allows us to design surfaces that can either repel or attract liquids, which is important for applications like self-cleaning materials or surfaces that avoid fouling.”

The team focused on two materials, silicon dioxide (SiO₂) and silicon carbide (SiC), which each offered unique properties.

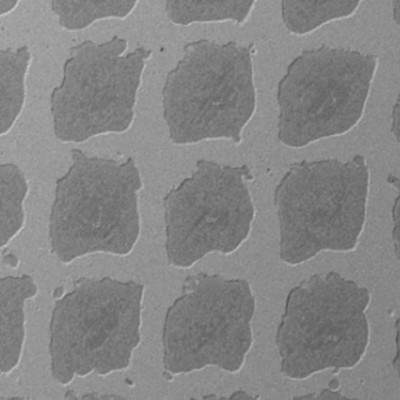

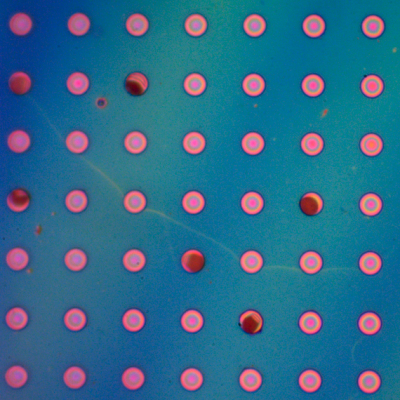

While SiC is known for its inherent hydrophobic (water-repelling) nature, the researchers found the overall geometry – especially the spacing and shape of these tiny cap-like structures – played a more significant role in influencing liquid behaviour than the type of material itself.

They found re-entrant structures with larger gaps between them effectively trapped air pockets, enhancing water repellence and preventing the liquid from fully wetting the surface.

This intricate balance between material properties and structure provided a new perspective on designing highly efficient, liquid-repellent surfaces.

Dr Kashaninejad said the implications of these findings were wide-reaching.

“In environmental technology, self-cleaning surfaces could reduce maintenance costs and improve performance in sectors such as solar panels and water-repellent coatings. In the biomedical field, liquid-repellent materials could help develop medical devices that resist bacterial build-up, improving hygiene and patient safety.”

“These findings also open doors to creating materials that can withstand extreme conditions, such as high temperatures or harsh chemicals, using materials like silicon carbide.

“This study not only contributes to the growing body of knowledge in surface science but also positions Griffith University at the forefront of innovative materials design.”

Dr Kashaninejad said the team was hopeful further exploration of these properties would lead to even more advanced applications across multiple industries.

Read the original article on Griffith University.