The spaghetti is not intended to be a new food but was created because of the wide-ranging uses that extremely thin strands of material, called nanofibers, have in medicine and industry.

Nanofibers made of starch – produced by most green plants to store excess glucose – are especially promising and could be used in bandages to aid wound healing (as the nanofiber mats are highly porous, allowing water and moisture in but keeping bacteria out), as scaffolding for bone regeneration and for drug delivery. However, they rely on starch being extracted from plant cells and purified, a process requiring much energy and water.

A more environmentally friendly method, the researchers say, is to create nanofibers directly from a starch-rich ingredient like flour, which is the basis for pasta.

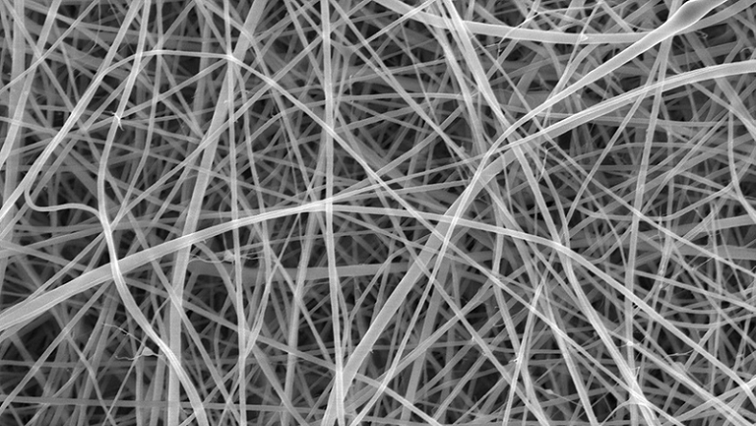

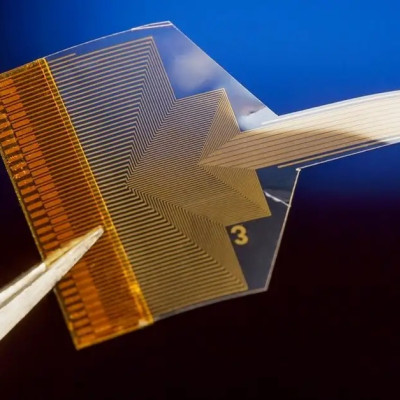

In a new paper in Nanoscale Advances, the team describe making spaghetti just 372 nanometres (billionths of a metre) across using a technique called electrospinning, in which threads of flour and liquid are pulled through the tip of a needle by an electric charge. The work was performed by Beatrice Britton, who carried out the study as part of her master’s degree in chemistry at UCL.

Co-author Dr Adam Clancy (UCL Chemistry) said: “To make spaghetti, you push a mixture of water and flour through metal holes. In our study, we did the same except we pulled our flour mixture through with an electrical charge. It’s literally spaghetti but much smaller.”

In their paper, the researchers describe the next thinnest known pasta, called su filindeu (“threads of God”), made by hand by a pasta maker in the town of Nuoro, Sardinia. This pasta lunga (“long pasta”) is estimated at about 400 microns wide – 1,000 times thicker than the new electrospun creation, which, at 372 nanometres, is narrower than some wavelengths of light.

The novel “nanopasta” formed a mat of nanofibers about 2 cm across, and so is visible, but each individual strand is too narrow to be clearly captured by any form of visible light camera or microscope, so their widths were measured with a scanning electron microscope.

Co-author Professor Gareth Williams (UCL School of Pharmacy) said: “Nanofibers, such as those made of starch, show potential for use in wound dressings as they are very porous. In addition, nanofibers are being explored for use as a scaffold to regrow tissue, as they mimic the extra-cellular matrix – a network of proteins and other molecules that cells build to support themselves.”

Dr Clancy said: “Starch is a promising material to use as it is abundant and renewable – it is the second largest source of biomass on Earth, behind cellulose – and it is biodegradable, meaning it can be broken down in the body.

“But purifying starch requires lots of processing. We’ve shown that a simpler way to make nanofibers using flour is possible. The next step would be to investigate the properties of this product. We would want to know, for instance, how quickly it disintegrates, how it interacts with cells, and if you could produce it at scale.”

Professor Williams added: “I don’t think it’s useful as pasta, sadly, as it would overcook in less than a second, before you could take it out of the pan.”

In electrospinning, the needle in which the mixture is contained and the metal plate upon which the mixture is deposited form two ends of a battery. Applying an electrical charge makes the mixture complete the circuit by streaming out of the needle on to the metal plate.

Electrospinning using a starch-rich ingredient such as white flour is more challenging than using pure starch, as the impurities – the protein and cellulose – make the mixture more viscous and unable to form fibres.

The researchers used flour and formic acid rather than water, as the formic acid breaks up the giant stacks of spirals (or helices) that make up starch. This is because the layers of helices stuck together are too big to be the building blocks of nanofibers. (Cooking has the same effect on the starch as the formic acid – it breaks up the layers of helices, making the pasta digestible.)

The formic acid then evaporates as the noodle flies through the air to the metal plate.

The researchers also had to carefully warm up the mixture for several hours before slowly cooling it back down to make sure it was the right consistency.

Lead author Beatrice Britton said: “I really enjoyed the iterative process of adjusting the variables and observing how this changed the mixture. It was a lot of trial and error – I didn’t think I would form fibres but I did. Thank you to Adam and Gareth for being so helpful and ready to answer the questions I had.”

Read the original article on University College London.