Scientists in Thailand have analyzed three organic phase-change material (PCM) mixtures with nanoparticles to cool PV modules and boost efficiency. They used organic fatty acid lauric acid (LA), mixing it with aluminum oxide (Al2O3), copper oxide (CuO), and magnesium oxide (MgO) in an optimal 94:6 weight ratio.

“Organic PCM has been selected due to its lower density than other types, which could potentially influence its lightweight characteristics,” the group said. ”This study significantly reduced the cost of the metal-oxide nanoparticle enhancer compared to other nanoparticles used in previous research.”

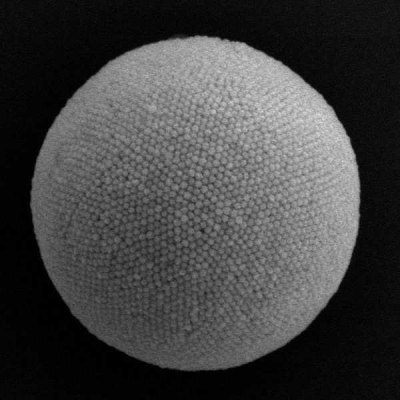

The team selected the 94:6 weight proportion based on previous experiments. They prepared the mixture using LA with at least 99% purity, Al2O3 with a particle size of 44 μm, MgO at 125 μm, and CuO at 44 μm. The PCM was placed in a 0.128 m² acrylic container, 3 mm thick, and attached to the back of the PV modules. They tested four 20 W polycrystalline modules: three with one of the PCM mixtures and one without PCM as a reference.

“After incorporating nanoparticles into the PCM and filling the container, nanoparticle dispersion and nanoparticle composited (nc)-PCM stability must be maintained,” the researchers said. “This can be achieved by inverting the container every 5 min throughout the cooling phase until it solidifies. During the test, some of the nc-PCM underwent a change from solid to liquid as they absorbed heat from the PV module, which led to their melting. This could result in a non-uniform, even distribution of nanoparticles within the PCM.”

The researchers positioned all PV modules at a 45 tilt angle under artificial light with an intensity of 1,000 W/m². Ambient temperatures in Thailand reached 38 C, while the PCMs melted at temperatures between 41 C and 44 C. They conducted three experiments in August 2023 and averaged the results for analysis.

“The back surface cooling technique of the PV module installed in the PCM container contributed to a 5.2 C (9.20%), 4.3 C (7.63%), and 2.9 C (5.2%) decrease in the average temperature of LA: MgO, LA: Al2O3, and LA: CuO, respectively,” the scientists said. “Thus, the electrical efficacy of the average PV module was enhanced by 14.11% (LA: MgO), 9.64% (LA: Al2O3), and 8.43% (LA: CuO).”

The results showed that the modules’ power output increased by 14.18% for LA: MgO, 9.69% for LA: Al2O3, and 8.47% for LA: CuO. An economic analysis found MgO to be the most cost-effective option, priced at $2.19 per kg. By comparison, Al2O3 costs $13.10/kg, and CuO is priced at $31.19/kg.

They presented their findings in “Thermal management of photovoltaic module using affordable organic phase change material combined with nano metal oxide particles enhancer,” recently published in Heliyon. Researchers from Thailand’s Khon Kaen University and Chiang Mai University conducted the study.

Read the original article on pv magazine.