The Company currently has the capacity to produce up to 40 tonnes of graphene annually. As part of its growth initiative, the Company is undertaking a significant expansion that will increase its production capacity to 140 tonnes per annum, more than tripling its current capacity. This scale-up will position the Company among the leading graphene producers globally.

The additional production unit will be installed within the Company's existing operational facility located at Thomas Swan & Co. Ltd. in the UK. This site already comprises a well-established infrastructure, with power and other essential utilities required for expansion. By leveraging the existing site and utilities at the Thomas Swan facility, the Company will be able to minimize capital expenditure, reduce lead times for installation, and accelerate the path to increased commercial output.

The increased production capacity will not only support existing customer relationships but also enable the Company to meet the requirements of new strategic partners seeking reliable and scalable graphene supply.

Simon Marcotte President and Chief Executive Officer, commented: "This expansion marks a pivotal milestone in our evolution; it is not just an increase in production capacity, but another step toward industrial scale. As demand for our products increases and several customer development programs are advancing, this investment positions us to meet both current and future market needs with confidence."

The new equipment includes a GEA Ariete 3160 unit, that is currently well advanced in its design, engineering and tailored to Black Swan's proprietary specifications. In collaboration with technology partner GEA, a global leader in high-pressure homogenization systems, the equipment is expected to be completed and installed in the short term at the Company's facility in Consett, United Kingdom, marking a pivotal step toward increasing production capacity from the current 40 tonnes annually to an impressive 140 tonnes per year.

The enhanced capacity is being driven by the successful execution of commercial agreements and strategic partnerships across the polymers, concrete, and advanced composites industries, and by an expanding sales pipeline.

The 3160 is a modular, scalable high-pressure homogenizer designed to handle the production of graphene nanoplatelets at industrial scale. Its development leverages the strong collaboration between Black Swan and GEA, which began over a decade ago. This partnership has produced a robust, proprietary exfoliation process capable of producing high-quality graphene products cost-effectively and reliably - a critical factor in unlocking large-volume applications for this transformational material.

This investment is funded in part by proceeds from the Company's recent equity financing. In addition to the equipment purchase, the funds supported the hiring of key sales and operations personnel, expanding Black Swan's ability to serve clients globally and to deepen commercial engagement.

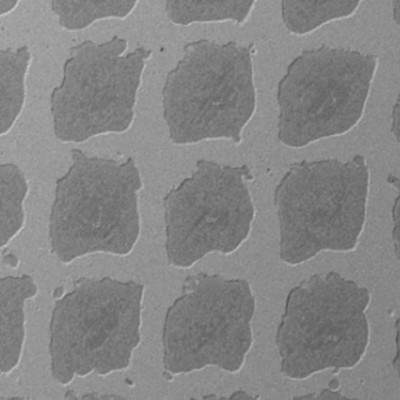

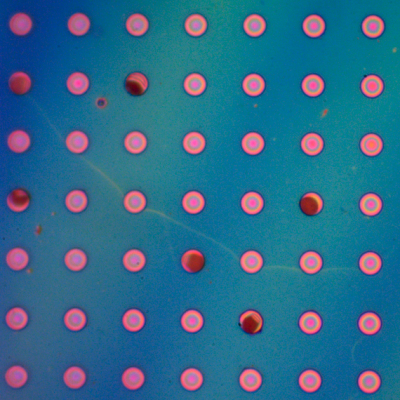

Michael Edwards, Chief Operating Officer, commented: "Graphene-enhanced materials are moving from promise to deployment, and Black Swan is at the center of that transition. With our Graphene Enhanced Masterbatch™ (GEM) polymer products now in commercial rollout and our concrete admixtures showing clear sustainability gains, our ability to deliver consistently and at scale is what sets us apart."

Black Swan has already launched seven GEM polymer products, which are being well received by the market, and the concrete admixtures, developed in partnership with Concretene and The University of Manchester's GEIC, are positioned to reduce cement usage and carbon emissions by up to 30%. The new 3160 system will ensure that this growing product portfolio can be delivered at scale and with the consistency demanded by global clients.

Read the original article on Graphene-Info.